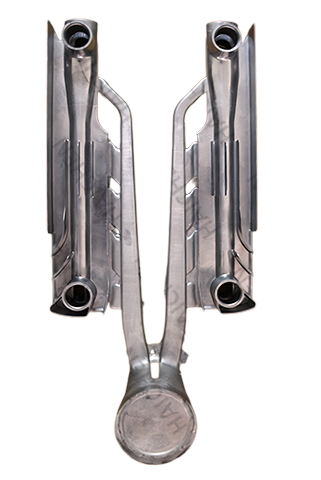

The advantages of aluminium radiators include: lightweight, efficient heat conduction, energy saving, corrosion resistance, environmentally friendly, easy installation and modern and diverse appearance.We use Aluminium radiators die casting machine for production.

However, aluminium radiators also have some disadvantages, such as lower strength, easy to deform, shorter service life, sensitive to pressure instability, prone to leakage, and rapid heat dissipation but also rapid cooling.

Aluminium radiators are mainly produced by cold chamber die casting machines.

This process is capable of producing radiators with complex shapes, high precision and good thermal conductivity and corrosion resistance.

Advantages of die-casting aluminium radiators for die-casting production

Die casting production of aluminium radiators has the following advantages:

- High thermal conductivity of aluminium die-casting radiators

- Aluminium die-casting radiators are lightweight and durable

- High precision and consistency of aluminium die-cast radiators

- Aluminium die casting radiator design flexibility

- Energy saving and environmental protection

- High production efficiency of aluminium die-casting radiator

- Aluminium die-casting radiator corrosion resistance

- Modular design of aluminium die-casting radiator

Aluminium die-casting radiator high thermal conductivity

Alloy Aluminium has excellent thermal conductivity, can quickly transfer heat, improve the efficiency of heat dissipation, especially suitable for electronic equipment and automotive and other high heat dissipation needs of the field.

Aluminium die-casting radiator is lightweight and durable

Cold chamber Aluminium die-casting heat sinks are lightweight but strong, suitable for portable devices and can be used for a long time under harsh conditions.

Radiators form Aluminium die-casting are highly accurate and consistent

Aluminium die casting process can produce highly accurate and dimensionally consistent castings with smooth surfaces, saving costs by eliminating the need for additional machining.

Aluminium die casting radiator design flexibility

High pressure cold chamber die casting can achieve complex shapes and thin-walled design, to meet the individual needs of aluminium die casting radiator, suitable for a variety of application scenarios.

Energy saving and environmental protection

Aluminium can be recycled, less resource consumption in the manufacturing process, in line with the modern environmental protection concept.

High production efficiency of aluminium die-casting radiator

D ie casting equipment for aluminium has high production efficiency, suitable for mass production, reducing the unit cost.

Aluminium die casting radiator corrosion resistance

Die casting Metal Aluminium has good antioxidant and corrosion resistance, aluminium die casting radiator has long service life and low maintenance cost.

Aluminium die-casting radiator modular design

Aluminium die-casting radiator adopts modular combination design, easy to install and maintain.

These advantages make aluminium die-casting radiator widely used in many industries, and continue to promote its technological progress and market expansion.

Different die-casting machine methods for aluminium radiators

The different die-casting machines for aluminium alloy radiators mainly include the following four types:

- Aluminium alloy radiator high pressure die-casting machine

- Aluminium alloy radiator semi-solid die-casting machine

- Aluminium alloy radiator low pressure die casting machine

- Aluminium alloy radiator composite die-casting machine

- Aluminium alloy radiator high pressure die casting machine

Aluminium alloy radiator high pressure die-casting machine

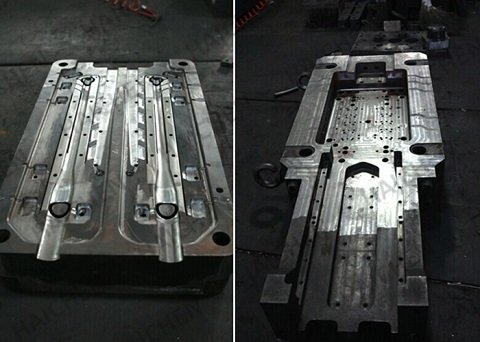

Liquid aluminium alloy is injected into the mould under high pressure and quickly cooled and shaped.

It is suitable for manufacturing radiators with complex shape and high precision.

This way can produce uniform wall thickness, smooth surface of the radiator, and high dimensional accuracy, usually reach 6 ~ 7, and even can reach 4.

Aluminium alloy radiator semi-solid die-casting machine:

By adjusting the pouring temperature of aluminium alloy, make it in semi-solid state, and then die-casting moulding.

This method can improve the organisational structure and mechanical properties of castings.

Aluminium alloy radiator low pressure die casting machine

Suitable for the production of thin wall thickness or simple shape of the radiator.

This method is less costly, but the mould and Aluminium radiators die casting machine requirements are higher.

Aluminium alloy radiator composite die-casting machine

Combines the dual material advantages of die-cast aluminium and steel or stainless steel tubes for manufacturing composite radiators.

This method improves the pressure-bearing capacity and corrosion resistance of the radiator.

Different aluminium alloy radiators can be produced using various types of aluminium alloy radiator die casting machines, the specific choice of which method depends on the product design requirements and production efficiency considerations.

Advantages of Haichen aluminium radiators cold chamber die casting machines

Haichen aluminium radiator cold chamber die casting machine tool quality and competence in many ways.

There are eight main aspects:

- High precision and surface quality

- Efficient production

- Suitable for a wide range of materials

- Economic benefits

- Complex geometry

- Durability and strength

- Automation and stability

- Wide range of applications

High precision and surface quality

Cold chamber die casting machine is capable of producing aluminium radiator with high dimensional accuracy and surface finish.

Tolerance grade up to IT13~IT15, low surface roughness, suitable for complex shapes and high requirements of parts production.

Efficient production

Cold chamber die casting machine production efficiency is high, each hour can die casting 50 ~ 90 times, suitable for large-scale aluminium radiator mass production.

Applicable to a variety of materials

Aluminium radiators die casting machine is suitable for aluminium alloy, brass, copper alloy and other high melting point metal processing.

It avoids corrosion problems and ensures material performance.

Economic benefits

Due to the accurate size and smooth surface of aluminium radiator parts, no secondary processing is required, reducing the waste of raw materials and processing costs, and improving the economic benefits.

Complex geometry

Cold chamber die casting can produce parts with complex geometry and thin wall.

Such as the minimum wall thickness can be up to 0.5mm (aluminium alloy). Especially suitable for the production of aluminium radiator.

Durability and strength

Cold chamber die castings have high strength and durability, suitable for the production of high-strength, lightweight and durable aluminium radiator.

Automation and stability

Cold chamber die casting machine is easy to automate production.

The stable operation of the equipment improves the production efficiency and product quality of aluminium radiator.

Wide application areas

Cold chamber die casting machine is widely used in automotive, aerospace, consumer electronics and other industries, to meet the requirements of different areas of material properties.

Haichen aluminium radiator cold chamber die casting machine plays an important role in modern manufacturing industry with its advantages of high precision, high efficiency production, strong applicability and high economic efficiency.