Magnesium die casting is a popular manufacturing process for producing lightweight, high-strength components, particularly in the automotive, aerospace, and electronics industries. However, it also has some limitations.

Magnesium die casting is a specific technique employe to fabricate quality, lightweight metal components. As it provides unique benefits along with challenges it is very important for manufacturers to understand self optimised production techniques and materials to use for their applications.

This article will cover the pros and cons of magnesium die casting, its unique versatile manufacturing features.

We will mengtions several of magnesium die casting applications across different industries to show how optimized production achieved to support die casting proposed benefits.

Advantages of Magnesium Die Casting

- Lightweight and High Strength

- Excellent Casting Properties

- Good Mechanical Properties

- Easy Machining

- Cost-Effectiveness

- Environmental Friendliness

- Good Thermal Conductivity

Lightweight and High Strength

Magnesium alloys are, structurally, the lightest of metals with a density of roughly 1.74 g/cm³. This is a third of aluminum and a seventh of steel. Because of their very high strength to weight ratio, magnesium alloys are use in aerospace, automotive, and portable electronic industries where weight saving is a major design criterion.

Excellent Casting Properties

Magnesium alloys are characterize by their high fluidity and rapid solidification, features that are advantageous to die casting processes. Parts produced by die casting are notable for their surface detail and dimensional accuracy. Also, these alloys increase die casting production rates: it is 4X faster than aluminum and 50% more efficient than magnesium die alloys and faster than the conventional aluminum die cast.

Good Mechanical Properties

Magnesium alloys are able to absorb vibrations and reduce noise which extends the life and mechanical efficiency of components exhibiting best impact resistance and impact stability. Thus they are suitable to high impact and precise applications.

Easy Machining

Magnesium alloys can be machine quickly which lowers the cost of tools and machining which increases overall efficiency.

Cost-Effectiveness

Magnesium’s price and abundance, combined with the ease of machining and durability of alloys decreases the need for replacements, providing economical profit.

Environmental Friendliness

Magnesium alloys resonates with eco-friendly sustainability practices as they are recyclable and non-poisonous. Sustainability improves the efficiency of resources by reducing waste.

Good Thermal Conductivity

Magnesium alloys can be used for applications which need good thermal conductivity, for example, heat sinks and electronic enclosure which require rapid dissipation of heat.

Disadvantages of Magnesium Die Casting

- Limited Corrosion Resistance

- Flammability

- High Mold Costs

- Design Flexibility

- Potential Porosity

Limited Corrosion Resistance

New magnesium alloys are still performing poorly with corrosion resistance in comparison to alloys made of aluminum, titanium or steel. Protective techniques for corrosion are essential in places with high industrial exposures.

Flammability

Strict safety techniques are needed for the processing and handling of magnesium powder or chips as they can catch fire when exposed to air.

High Mold Costs

For magnesium die casting, the specialized molds that are required can be expensive and difficult to design and manufacture. For minor production runs, this foundational investment might not make sense.

Design Flexibility

After a mold has been made, making changes to the cast part’s design is nearly impossible without incurring a large expense.

Potential Porosity

During the die casting cycle, for some reason cast air can become confined in the process which results in the part becoming porous and can lead to weakened strength.

HAICHEN’s Magnesium Die Casting Solution: A Systematic Approach to Industry Challenges

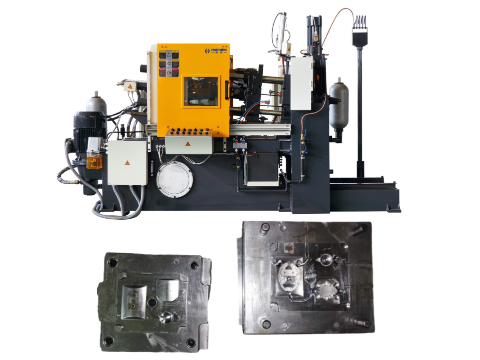

HAICHEN provides a complete system solution, from equipment to process, to address the inherent challenges of magnesium die casting. Our cold chamber machines integrate vacuum and argon protection systems to effectively prevent oxidation and combustion of molten magnesium. The high-precision intelligent temperature control, combined with optimized mold design, helps reduce thermal stress and slow down mold wear, tackling the high mold cost issue. Moreover, a stable and repeatable injection process significantly minimizes internal porosity.

Application Case: When producing a magnesium alloy dashboard crossbeam bracket for a new energy vehicle customer, HAICHEN’s systematic solution successfully kept the product’s porosity at a very low level and significantly improved the adhesion of the corrosion-resistant coating. The mold life met and exceeded the expectation of 300,000 shots. This solution helped the customer achieve substantial weight reduction for the component while increasing the overall product yield to over 98.5%, reducing extra costs associated with mold maintenance and scrap.

Magnesium Die Casting machine supplier: Haichen Machinery

Haichen Machinery is a Chinese firm that focuses on the production and distribution of magnesium cold chamber, hot chamber machines and other complementary devices. We provide a number of die casting services such as cold chamber die casting that is frequently used for casting non-ferrous alloys like aluminum and magnesium, and other die casting machines.

Die casting of magnesium has become increasingly popular in modern industry, and is a common method of manufacturing in the automotive and aerospace sectors for its light weight, high efficiency, and superb mechanical qualities. However, technological innovation and advancements in process refinement are required to solve issues such as high cost, poor corrosion resistance, and flammability.