Advantages of aluminium die casting includ high strength and lightweight, ability to produce complex geometries and so on.

Aluminum Die Casting offers several significant advantages that make it an ideal choice for manufacturing complex metal parts.

Advantages of aluminium die casting: High Strength and Lightweight

Aluminum die castings have an excellent strength-to-weight ratio. That makes them very popular in applications. That requires lightweighting while maintaining high strength, such as the automotive and aerospace industries.

Advantages of aluminium die casting: Ability to produce complex geometries

Aluminum die casting is able to produce parts with complex shapes. And aslo sharp contours and thin walls, which are difficult to achieve with other metal forming processes. This capability is particularly suitable for manufacturing complex parts such as automotive gearboxes, engine cylinders, etc.

Advantages of aluminium die casting: Dimensional stability and precision

Aluminum die castings have extremely high dimensional stability. They can meet strict tolerance requirements (±0.075 mm), and maintain high precision during production.

Advantages of aluminium die casting: Excellent surface quality

Aluminum die castings can provide smooth or textured surfaces without the need for additional post-processing. That can reduce production costs and improves efficiency.

Corrosion resistance

Aluminum die castings have good corrosion resistance and can be used in harsh environments, extending the service life of the product.

Thermal and Electrical Conductivity

Aluminum’s high thermal and electrical conductivity make it an ideal choice for electronic devices, heat sinks, and other applications that require thermal management and electrical energy transfer.

Environmental protection and sustainability

Aluminum is a recyclable material, and aluminum die castings are 100% recyclable, which meets the needs of modern industry for environmental protection and sustainable development.

High production efficiency

Aluminum die casting is a highly automated production method. It with high productivity and short production cycle. That is particularly suitable for mass production.

Cost-effectiveness

Although the equipment and mold costs are higher. The production efficiency and material utilization of aluminum die casting make it cost-effective in large-scale production.

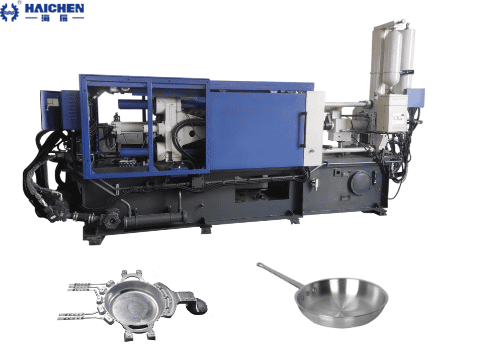

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

When you have any demand of selecting cold chamber die casting machine, feel free to contact us.