Aluminum die casting provides modern cookware with advantages like superior heat distribution, durability, lightweight design, and affordability.

The die-casting process creates cookware that is resistant to warping, heats up quickly and evenly to prevent hot spots, and is lighter than cast iron for easier handling.

Its rivet-free construction, electromagnetic compatibility design, and fast-response temperature control feature make it an ideal choice for efficient kitchens.

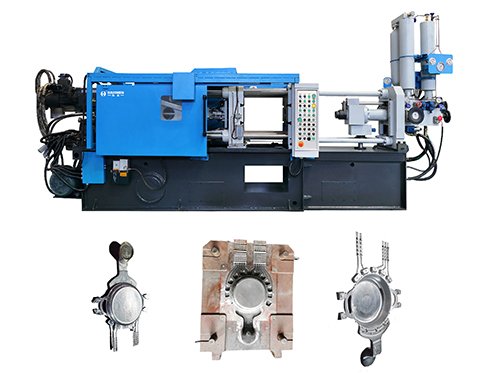

If you want to find a suitable die casting machine to produce aluminum cookware, you can consult haichen.

What is Aluminum Die Casting Cookware?

Aluminum Die Casting Cookware is produced using a high-pressure casting process.

This involves pouring molten aluminum alloy into a mold under high pressure to form cookware with a consistent and durable structure.

Haichen‘s die casting machines are all high-pressure die casting machines,unlike other manufacturing methods.

Such as stamping or machining from solid blocks, die casting allows for the creation of complex shapes with high precision while maintaining a lightweight design:

- Depth and Design

- Material Benefits

- Versatility

Depth and Design

The process enables the production of pans with deeper sides (typically between 3 to 6 inches), which helps contain hot oil and reduces splatter during cooking.

Material Benefits

Aluminum is an excellent heat conductor. It heats up quickly and distributes heat evenly, which is crucial for achieving consistent cooking results.

Additionally, die cast aluminum is often more affordable compared to other metals, making it a cost-effective option.

Versatility

Modern die cast aluminum pans are available in various forms and can be treated with surface coatings.

Such as anodizing or ceramic layers, to improve durability and reduce reactivity with food.

Overall, die cast aluminum cookware represents a fusion of advanced manufacturing techniques with practical cooking benefits, making it a strong contender in the modern kitchen.

A combination of lightness and strength

Aluminum die-cast cookware is popular for its lightness, which makes the cookware easy to carry and operate, even when it is full of food.

In addition, the aluminum die-casting process enables the creation of high-strength, durable cookware, such as pots and pans, with thicker bottoms and sides, for added durability.

Excellent thermal conductivity

Aluminum alloy has excellent thermal conductivity, which allows aluminum die-cast cookware to evenly distribute heat, resulting in even heating, ensuring perfect results for every cooking.

It is worth mentioning that this characteristic is particularly suitable for cooking methods that require even heating.

Non-stick coating and ease of cleaning

Aluminum die-cast cookware is usually equipped with a non-stick coating.

Which not only makes cooking more convenient, but also greatly simplifies the cleaning process.

It can be easily cleaned with just a soft cloth and warm water.

This non-sticky property also avoids the accumulation of food debris and further improves the hygienic performance of the cookware.

Corrosion Resistance & Durability

Aluminum die-cast cookware has good corrosion resistance and can be used for a long time without rusting even in wet environments.

This property makes aluminum die-cast cookware an affordable and long-lasting option.

Design Flexibility & Aesthetics

The aluminum die casting process allows for the manufacture of intricate shapes and finely designed cookware.

Which not only enhances the aesthetics but also enhances the functionality of the cookware.

For example, modern aluminum die-cast cookware can be designed as a thin-walled structure that is both aesthetically pleasing and functional.

Eco-friendly & Efficient

Production Aluminum die casting is an efficient and environmentally friendly manufacturing process that enables the rapid production of high-quality parts while reducing scrap and energy consumption.

This process not only improves production efficiency, but also reduces production costs.

Versatility & Compatibility

Aluminum die casting allows for customization of different cookware, and Haichen’s mold design team can adapt them to a variety of cooking styles according to the manufacturer’s requirements. Including a pan, or a cooking pot.

Haichen die casting manufacturing

Haichen is an expert in the field of high-pressure aluminum die casting.

The key to the die casting process lies in precision, speed and consistency.

The high pressure forces the metal into every tiny crevice of the mold, thereby creating parts with extremely high precision and extremely fine details, with the precision reaching the final shape or very close to it.

This means that when the parts are taken out of the mold, they are already very close to the final shape, minimizing the time and cost of secondary processing.

Steel molds are very durable and can be used to produce tens of thousands of identical parts, making them an efficient and economical process for large-scale production.

When customers bring us the design drawings of the aluminum cookware, we will utilize our professional technical expertise in aluminum die-casting to transform the digital design into tangible and high-performing physical components that are within reach.

Why choose Haichen?

Our company specializes in high-pressure die casting and offers precise, efficient and versatile high-pressure die casting machines.

Whether you need a production line for aluminum pots, frying pans or other aluminum cookware, we can provide it for you.

Have you ever thought about how aluminum die casting can assist your next project?

Contact us immediately and let’s explore all the possibilities together!