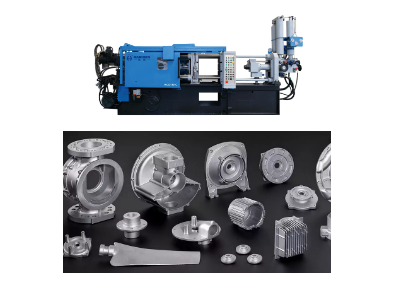

Aluminum die casting parts offer high strength-to-weight ratios, excellent corrosion resistance, and precise dimensional accuracy, making them ideal for lightweight, durable applications in automotive, aerospace, and consumer electronics.

Aluminum die – casting parts are widely used across various industries due to their unique combination of properties and benefits.

These parts offer a range of advantages that make them ideal for modern manufacturing processes. This article will explore the numerous advantages of aluminum die – casting parts and how they contribute to efficient and effective production processes.

By understanding these benefits, manufacturers can make informed decisions to optimize their production strategies and achieve high – quality results.

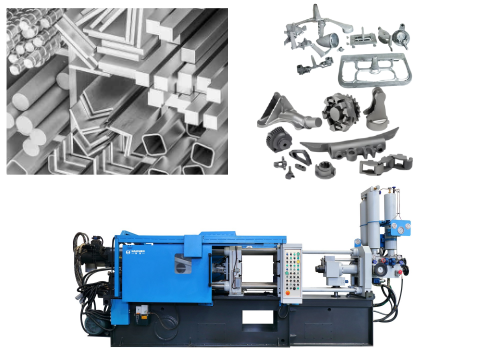

Lightweight and High Strength

One of the most significant advantages of aluminum die castings is their excellent strength-to-weight ratio. This is crucial for many industries.

- Material Savings and Improved Energy Efficiency

- Excellent Mechanical Properties

- Thin-Wall Forming Capability

Material Savings and Improved Energy Efficiency

Aluminum alloy parts are significantly lighter than iron or steel parts. In vehicles, this reduces weight, leading to improved fuel efficiency and reduced emissions.

Excellent Mechanical Properties

Aluminum parts are not only lightweight but also strong. Commonly used alloys such as ADC12 and A380 exhibit excellent tensile strength and hardness. This allows them to withstand stress, vibration, and wear in demanding applications.

Thin-Wall Forming Capability

Thanks to the excellent fluidity of molten aluminum, this process can form thin-walled parts with uniform wall thickness. Thin-wall designs further reduce material usage, decrease weight, and allow for faster cooling, thus shortening production cycles.

Precision and Complexity

Aluminum die casting allows for the production of highly precise and complex parts with tight tolerances. The high-pressure injection process ensures that the molten aluminum fills even the most intricate mold cavities, resulting in parts with excellent dimensional accuracy and surface finish.

This precision is critical for applications such as electronic housings, where tight tolerances are necessary to ensure proper fit and function.

Cost-Effective

Aluminum die casting is a cost-effective manufacturing process, especially for high-volume production. The ability to produce large quantities of parts quickly and with minimal waste makes it an economically viable option.

Additionally, the durability and longevity of aluminum parts reduce the need for frequent replacements, further lowering overall costs.

Design Flexibility

Aluminum die casting offers significant design flexibility. Engineers can create parts with complex geometries and integrated features, reducing the need for secondary operations and assembly.

This not only saves time and money but also enhances the overall performance and functionality of the final product.

Energy Efficiency

Aluminum is a highly recyclable material, and die casting processes can be designed to minimize energy consumption.

HAICHEN, a leading die casting machine manufacturer, focuses on developing energy-efficient machines that reduce operational costs and environmental impact.

By using advanced control systems and optimized processes, HAICHEN machines ensure that aluminum die casting remains a sustainable manufacturing choice.

Aesthetic Appeal

Aluminum die casting parts can achieve excellent surface finishes, making them suitable for applications where appearance is important. The ability to produce parts with smooth surfaces and fine details enhances their aesthetic appeal, which is particularly valuable in consumer electronics and automotive exteriors.

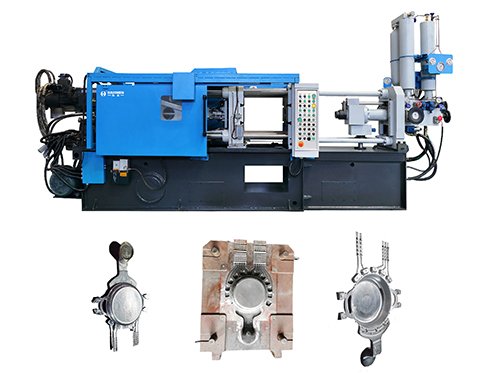

Application Case: Achieving Advantages with HAICHEN

To fully get the advantages of aluminum die casting parts, high-performance and stable equipment is essential. HAICHEN die casting machines help turn these potential benefits into high-quality end products through precise process control.

- Case: Producing an Aluminum Deep Fry Pan on a 650-Ton Machine

- How Key Technologies Secure the Advantages

- Overall Value for the Customer

Case:Producing an Aluminum Deep Fry Pan on a 650-Ton Machine

A cookware manufacturer uses a HAICHEN 650-ton cold chamber die casting machine to produce large aluminum deep fry pans (specs: 280mm diameter, 70mm height, 2.8-4mm wall thickness, ~1kg weight). The product demands high uniformity in wall thickness, surface flatness, and heat distribution.

How Key Technologies Secure the Advantages

The stable clamping force of the HAICHEN machine ensures the large mold stays tightly closed during high-pressure injection, preventing flash. Its multi-stage precision injection control allows molten aluminum to fill the mold cavity smoothly and quickly. This perfectly forms the gradual thin-wall structure from the pan bottom to the side wall, avoiding defects like cold shuts or trapped air. Combined with an efficient mold temperature control system, it ensures stable part dimensions and a fine microstructure.

Overall Value for the Customer

This solution enables high-yield, single-step production of the complex thin-wall pan. It fully utilizes the advantages of aluminum die casting parts: light weight, high thermal conductivity, and good surface quality. The efficient and stable production helps the customer meet market demand quickly and gain a competitive edge with a superior product.

Advantages of Aluminum Die Casting Parts including high strength, lightweight, precision, cost-effectiveness, design flexibility, energy efficiency, and aesthetic appeal. These benefits make aluminum die casting a preferred choice for a wide range of industries.

With manufacturers like HAICHEN leading the way in die casting technology, the future of aluminum die casting looks promising. Whether for automotive components, consumer electronics, or industrial applications, aluminum die casting continues to play a crucial role in modern manufacturing.