Advantages of die casting process:

- High Production Efficiency

- Precision and Consistency

- Excellent Surface Finish

- Cost-Effectiveness

- Strength and Durability

- Material Versatility

- Complex Geometries

- Recyclability

The die casting process offers numerous benefits for producing high-quality metal parts with precision and efficiency.

The die casting process offers numerous advantages that make it a popular choice in modern manufacturing.

High Production Efficiency

Die casting allows for the rapid production of large quantities of identical parts.

Its automated nature and short cycle times enable manufacturers to produce a significant number of components in a short period.

This makes it highly suitable for high-volume manufacturing.

Precision and Consistency

The process achieves a high degree of precision and consistency. It can produce parts with complex shapes, intricate details, and tight tolerances.

Every part is virtually identical, reducing defect rates and ensuring uniform quality.

Excellent Surface Finish

Die cast parts typically have smooth surfaces with minimal imperfections. In many cases, no additional finishing operations are required.

This not only enhances the aesthetic appeal of the products but also reduces the need for secondary processes, lowering overall production costs.

Cost-Effectiveness

Despite the high initial costs associated with tooling and machinery, die casting becomes cost-effective in the long run.

The ability to produce large volumes quickly and with minimal material waste helps reduce unit costs. Additionally, the reduced need for secondary operations further contributes to cost savings.

Strength and Durability

Die cast parts are known for their strength and durability.

The high pressure used during the process results in dense, robust components with excellent mechanical properties.

These parts are often more durable and have higher tensile strength compared to those produced by other casting methods.

Material Versatility

Die casting is compatible with a wide range of non-ferrous metals, including aluminum, zinc, magnesium, and copper alloys.

This versatility allows manufacturers to choose materials based on specific mechanical properties required for their products.

Complex Geometries

The process can create highly complex shapes and thin-walled parts.

This capability is particularly advantageous for industries that require intricate and lightweight components, such as automotive and aerospace.

Recyclability

Die casting supports the recycling of materials. This not only reduces waste but also makes the process more environmentally friendly.

Die Casting Process

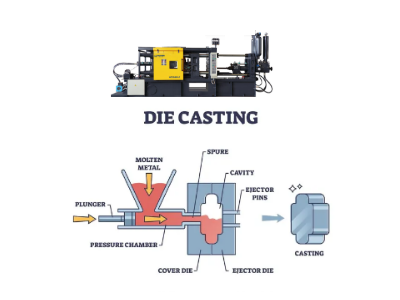

The die casting process is a metal casting process characterized by injecting molten metal into a reusable mold cavity under high pressure to produce metal parts with complex geometries, precise dimensions, and smooth surfaces.

This process is widely used in non-ferrous metals such as zinc, aluminum, and magnesium, and is suitable for automotive, electronics, industrial parts, and other fields.

Haichen die casting machine supplier

Haichen is a die casting machine supplier from China, specializing in the production of high-quality cold chamber and hot chamber die casting machines.

The company provides advanced solutions for aluminum, magnesium, zinc, and other non-ferrous alloy die casting applications.

Key Features of Haichen Die Casting Machines:

High Precision & Stability: Ensures consistent part quality with tight tolerances.

Energy Efficiency: Advanced hydraulic systems reduce power consumption.

Fast Cycle Times: Improves productivity for high-volume manufacturing.

Durable Construction: Robust machine design for long service life.

Smart Control Systems: PLC and CNC integration for automated operation.

If you’re looking for a reliable die casting machine supplier, Haichen offers a good balance of performance, durability, and affordability.