Aluminum pressure die casting advantages includes high effective production, excellent mechnical properties, manufacture complex geometries, etc.

High-pressure aluminum die-casting technology plays an important role in modern manufacturing due to its high efficiency, precision, economy and versatility. It is not only applicable to traditional industries such as automobiles, aerospace, electronics, etc., but also provides innovative solutions for emerging fields.

High Pressure Die Casting (HPDC) has several significant advantages that make it a widely used technology in modern manufacturing. These advantages include:

- High production efficiency

- Excellent mechanical properties

- Manufacture capabilities for complex geometries

- High Precision and Dimensional Stability

- Cost-effectiveness

- Surface treatment friendly

High production efficiency of Aluminum pressure die casting advantages

High pressure aluminum die casting can produce complex parts with extremely high speed and precision.

It can produce thousands of parts per hour, suitable for large-scale production. Its fast filling time and short cycle make it ideal for high-volume production needs.

Fast Production Cycles and High Output

Aluminum die casting uses high-pressure injection combined with efficient mold cooling technology to achieve rapid filling and solidification of molten metal. Cycle times are extremely short (typically in seconds), enabling high-volume production of parts.

For example, thousands of castings can be produced daily, making it particularly well-suited for large-scale orders in industries like the automotive industry.

Automation and Process Controllability

- The die casting process is highly automated, with precise control of the machine and molds ensuring consistent production.

- Molds can be reused hundreds of thousands of times, significantly reducing unit costs and increasing output per unit time.

- The automated process reduces manual intervention and achieves faster production speeds than sand casting or investment casting.

Reduced Need for Secondary Processing

Castings offer excellent dimensional accuracy (tolerances as low as 0.1mm) and surface finish (Ra 1-2.5μm), significantly reducing the need for subsequent machining.

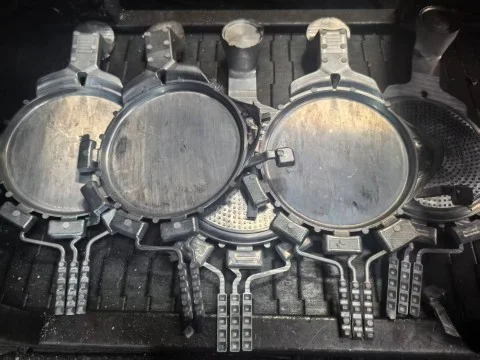

Haichen high pressure die casting aluminium alloy pot

For example, Haichen adpot high-pressure die casting (HPDC) to produce high-quality aluminum alloy cookware pots with exceptional efficiency and performance.

By injecting molten aluminum into precision steel molds under intense pressure, this process enables the rapid production of pots with complex, thin-walled geometries and excellent dimensional consistency. The result is lightweight yet durable cookware with superior heat distribution.

Key advantages include high production speeds, minimal material waste, and the ability to integrate reinforced structures and intricate surface details directly into the casting, ensuring both functional excellence and aesthetic appeal in every piece.

Haichen can also produce replaceable pot bottom moulds for same diameter with different bottom shape pans. That can help save and reduce customer’s significant cost.

Excellent mechanical properties

Aluminum alloys cool rapidly during the high-pressure die-casting process, forming a fine grain structure that improves strength and durability.

In addition, aluminum alloys also have good rigidity and a high strength-to-weight ratio, making them outstanding in lightweight applications.

Combine high strength with lightweight

- Aluminum die-castings offer an excellent strength-to-weight ratio. Aluminum alloys have a low density (approximately one-third that of steel).

- However, through high-pressure injection and rapid cooling, a fine-grained structure is formed, significantly improving strength and hardness.

High tensile strength and hardness

- Aluminum die-castings can achieve a tensile strength of 415 MPa (approximately 60 ksi).

- Some alloys (such as A380/A383) can achieve even higher strengths through process optimization.

Excellent toughness and impact resistance

Aluminum exhibits excellent toughness at both high and room temperatures, with particularly outstanding impact toughness.

Manufacture capabilities for complex geometries

High-pressure aluminum die casting is able to produce parts with wall thicknesses as thin as 1mm and can achieve complex internal details and thin-wall designs.

This capability allows designers to create lightweight and highly functional parts such as automotive parts and aerospace components.

Achieve High-Precision Complex Geometries

- High-pressure die casting, by injecting molten aluminum into precision molds at high speed, can produce complex geometries such as thin walls (down to 1mm), sharp angles, fine features, and undercuts.

- Typical examples include automotive transmission housings, electronic enclosures with built-in cooling channels, and thin-walled, high-rigidity brackets, all of which can be formed in a single die casting, eliminating the need for segmented production.

Dimensional Accuracy and Surface Quality

High-pressure injection combined with rapid cooling results in castings with high dimensional stability (tolerances down to ±0.1mm) and excellent surface finish (Ra below 1.6μm), reducing the need for subsequent machining.

For example, automotive parts can directly meet assembly precision requirements, eliminating milling steps.

Process flexibility supports innovative designs

- The use of core technology allows the creation of hollow structures, special-shaped runners, and other internal features not possible with traditional casting.

- This increased design freedom enables the integration of multifunctional components, such as heat sinks and structural components, into one die casting, optimizing product performance.

Cost-effective mass production

- Molds can be reused over 100,000 times, enabling high-volume production of complex parts at significantly lower unit costs.

- For example, the automotive industry can produce millions of geometrically consistent parts annually.

- Compared to machining or welding assembly, die casting reduces material waste by over 30%, making it particularly suitable for manufacturing lightweight, complex components.

High Precision and Dimensional Stability

High-pressure aluminum die casting is able to produce parts with extremely close dimensional tolerances and a high surface finish, reducing the need for subsequent machining.

This makes the process particularly suitable for industries that require precision machining, such as automotive and electronic equipment manufacturing.

High Dimensional Precision (Tight Tolerances)

Aluminum die casting can achieve extremely tight tolerances.

- Initial dimensional accuracy reaches ±0.1 mm (within the first 2.5 cm), with a deviation of only ±0.02 mm per additional cm (approximately ±0.004 inches for the first inch and ±0.002 inches per additional inch in imperial units).

- This high precision is achieved through high-pressure injection (40–120 MPa) and high-speed mold filling (30–80 m/s), enabling the molten aluminum to fill the mold cavity within 0.01–0.16 seconds, minimizing flow deformation.

Dimensional Stability of Aluminum pressure die casting advantages

- The die casting process utilizes precision molds (steel dies) and high-pressure solidification, ensuring highly consistent parts over repeated production runs and minimizing batch-to-batch variability.

- Rapid cooling under high pressure creates a fine-grained structure, reducing internal porosity and enhancing part density, thereby improving mechanical stability.

- Aluminum’s low coefficient of thermal expansion and optimized alloys (such as A380/A383) further ensure dimensional stability despite temperature fluctuations, making it suitable for high-temperature environments (such as automotive engine components).

Adaptability to complex designs

- It can produce ultra-thin-wall parts (down to 0.75 mm) while maintaining dimensional accuracy.

- Supporting lightweight and complex geometries (such as heat sinks and precision electronic components).

- Directly forming fine features (such as threaded inserts and thin ribs) reduces subsequent processing and the risk of deformation.

Cost-effectiveness

Despite the higher initial tooling costs, high pressure aluminum die casting has a lower unit cost, making it more economical, especially in large-scale production.

In addition, the process reduces material waste and post-processing costs, further improving economic benefits.

Low Material Costs of aluminum pressure die casting advantages

Aluminum alloys are significantly cheaper than other metals like copper, brass, and steel, and the die-casting process minimizes material waste, further reducing raw material costs.

Production Efficiency and Economies of Scale

- High Volume and Automation: The die-casting process is highly automated, enabling rapid production of large numbers of parts.

- For example, robotic die-casting cells can significantly improve efficiency, achieving production rates of thousands of parts per minute.

- Economy of Scale: While initial mold investment is high, the cost per part can be significantly reduced through large-scale production.

Process Integration Reduces Post-Processing

Die-cast parts typically exhibit high precision and excellent surface quality, reducing or even eliminating post-processing steps such as machining and polishing, thereby reducing labor and equipment costs.

Mold Reusability and Long-Term Cost-Effects

- Molds are reusable, and optimized design (such as MUD systems and standardized components) can further reduce mold costs.

- It emphasizes that despite the high initial tooling costs, significant long-term savings can be achieved through reduced scrap and high energy efficiency.

Surface treatment friendly of aluminum pressure die casting advantages

The parts produced by high-pressure aluminum die casting have smooth surfaces and are easy to be surface treated.

Such as sandblasting, polishing or electroplating. This provides more possibilities for the aesthetics and functionality of the product.

Excellent initial surface quality reduces the need for post-processing

- The die-casting process inherently produces high-precision, low-roughness surfaces, significantly reducing or even eliminating the need for additional surface finishing.

- Die-cast parts have a smooth, fine-grained surface immediately after demolding (typically with a surface roughness of Ra 1-2.5 μm or less).

Highly compatible with a variety of surface treatment processes

The excellent initial surface finish of aluminum alloy die-castings provides an ideal substrate for a variety of subsequent functional or decorative surface treatments.

Basic Performance Enhancement Treatment Effects

The inherent properties of aluminum alloy, combined with the die-casting process, provide an excellent foundation for surface treatment.

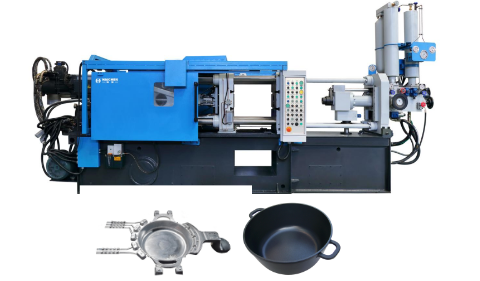

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.