Advantages of industrial robot for die casting machine includes improve production efficiency and product quality, reduce labor risk, save cost and so on.

What are the advantages of industrial robot for die casting machine?

The main advantages of industrial robot for die casting machine are to do hot, repetitive jobs instead of people, making the production cell automatic. This article will explain the specific advantages for safety, quality, and efficiency. It will describe common robot tasks. Then, a HAICHEN case will show how they offer complete solutions that combine robots and machines to work better together.

Die casting machine robots have significant advantages in many aspects, including improving production efficiency, ensuring quality control, improving safety, reducing production costs, enhancing flexibility and adaptability, improving environmental impact and optimizing the working environment. These advantages make die casting robots play an increasingly important role in modern manufacturing.

The main advantages of using an industrial robot with a die casting machine are to automate tasks like part removal and spraying. This increases production efficiency, keeps people safe, and makes product quality stable. This article will explain these specific advantages, show common robot tasks, and highlight HAICHEN’s skill in robot integration and the selling points of its die casting machines.

Industrial robots for casting machines has significant advantages, they mainly reflected in the following aspects:

- Improve production efficiency

- Improve automation

- Improve product quality and consistency

- Adaptability and flexibility

- Cost savings and improved economic benefits

Improve production efficiency

- Work without taking a break

- Adapt to new production needs

Industrial robots for die casting machine can replace traditional manual operations to automate the casting process. It can significantly improve production efficiency in the die casting process.

Work without taking a break

Firstly, the robot can work continuously without taking a break, thus achieving 24/7 uninterrupted operation. This continuous working mode allows the production line to complete tasks at a higher frequency and reduce production cycle time.

Adapt to new production needs

Secondly, Robots can also quickly adapt to new production needs.

For example, the industrial robots can easily reprogramm adapt to different product types and design changes. Thereby it can improve production flexibility. This flexibility enables manufacturers to respond faster to changes in market demand and improve overall production efficiency.

Improve automation

- Replace dangerous and repeat task

- Control of complex processes

The application of industrial robots in die-casting machines is an important means of achieving automation. Automation not only improves production efficiency, but also reduces reliance on manual labor.

Replace dangerous and repeat task

For example, robots can replace the dangerous and repetitive tasks that require a lot of manual operation in traditional die-casting processes. Thereby robots can reduce the labor intensity and work risks of workers.This automation not only improves production safety, but also reduces labor costs.

The foundry industry usually requires workers to perform high-intensity physical labor. And the industrial robots can replace these jobs, reduce labor intensity and operate risks. Moreover, the application of robots in high-risk environments also reduces the threat to worker safety.

Control of complex processes

The automation application of robots in the die-casting process also includes precise control of complex processes.

For example, robots can provide higher precision and control in the melting and die-casting processes. Thus ensuring consistency in product quality. This precise control capability enables robots to handle parts of various shapes and sizes. And also improving production efficiency and product quality.

Improve product quality and consistency

- Reduce product defects

- Precise control and monitor

Industrial robots can provide higher precision and consistency when performing post-casting cleanup (such as removing gates, parting lines, etc.).

Reduce product defects

The use of industrial robots in die casting machines can also significantly improve product quality. Robots can ensure high consistency in the production process, thereby reducing product defects.

For instance, robots can ensure the accuracy and consistency of each part, thereby reducing product defects. This consistency not only improves product quality, but also enhances customer satisfaction.

Precise control and monitor

Robots can also reduce waste in the production process through precise control and monitoring.

For example, robots can accurately handle materials, thereby reducing waste, improving production efficiency and product quality.

Through programming control, robots can accurately complete these tasks, thereby improving the quality and surface finish of castings.

Robotic casting

Robotic casting refers to using industrial robots to automate or assist in various stages of the casting process, including both metal casting (like die-casting and investment casting) .

Advantages of robotic casting

- Increased productivity and efficiency: Robots can perform tasks faster and more consistently than humans, leading to higher output.

- Improved quality: Precision control from robotic systems reduces errors, leading to more consistent and higher-quality parts.

- Enhanced worker safety: Robots handle dangerous jobs, such as working with hot metal, reducing the risk of injury to human workers.

- Greater flexibility: Automation allows for more flexible production, making it easier to meet fluctuating demand and adapt to different part types.

Adaptability and flexibility

- Handle various products

- Switch different product lines

Industrial robots are highly flexible and adaptable. They can quickly adjust work procedures and tool configurations according to different production needs.

Handle various products

Industrial robots are able to handle parts of various shapes, sizes and complexities, thus expanding the scope of die casting manufacturing. For example, robots can be quickly reprogrammed to adapt to new production needs, which allows manufacturers to flexibly respond to market changes.

Switch different product lines

In addition, robots can also switch between different production lines, thereby improving equipment utilization. This flexibility enables robots to cope with multi-variety, small-batch production requirements and meet the diverse needs of modern manufacturing.

Provide Automatic Solutions with Robot and Machine Teamwork

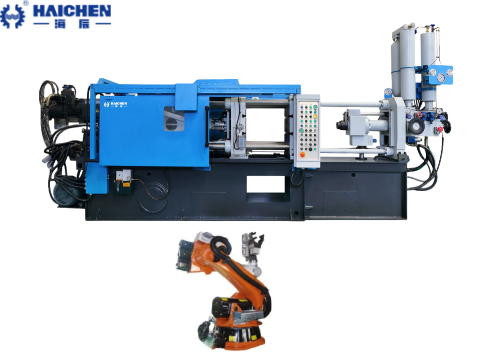

HAICHEN not only provides high-performance die casting machines but also has strong skills in robot integration. They build efficient and reliable “die casting machine + robot” production cells for customers.

Customer Need for Automation Upgrade

An aluminum part maker wanted to upgrade their manual part-removal and spraying line to an automatic cell. They needed more output and had to meet stricter safety rules.

HAICHEN’s Robot Integration Plan and Machine Selling Points

HAICHEN planned and set up a full automatic cell for them. It included a die casting machine, a six-axis robot, a sprayer, and a conveyor. This solution shows these teamwork selling points:

- Deeply Integrated Control System: HAICHEN’s machine control system and the robot controller share data and work together. The robot’s actions can start directly from the machine’s cycle signal. This connects them smoothly and reduces the delays or problems common in multi-system setups.

- Machine Design Made for Easy Automation: HAICHEN machines are designed with standard robot interfaces, safety signals, and enough free space around them. This makes robot setup easier and safer.

- Stable Die Casting Process is the Base: HAICHEN machines provide steady clamping force and repeatable injection profiles. This ensures stable part quality and cycle time. It is the foundation that lets the robot work efficiently and in good order.

Results and Value Added

After the automatic cell started, the customer fully automated part removal and spraying. Output per shift increased by 25%. Part damage rate fell by over 90%. Safety risks for those jobs were removed. Also, release agent use dropped by about 30%.

Haichen produce many different types of cating robots. It has single, double axis, triple axis robots series. They can meet various condition of die casting works. These die casting robots can enhance productivity, consistency, and enable workers safely by automating tasks. Haichen can supply suitable die casting robots model series as per your specific die casting industrial.

Cost savings and improved economic benefits

- Cost saving

- Reduce energy consumption

The industrial robots can significantly reduce labor costs. And also increase the competitiveness of enterprises by improving production efficiency and product quality.

Cost saving

The use of industrial robots in die casting machines can also significantly reduce production costs.

Firstly, robots can reduce labor costs because they can replace a large number of tasks that require manual operation. Secondly, Robots can significantly reduce labor costs because they reduce dependence on manual labor.

In addition, robots can reduce material waste because they can handle materials precisely, thereby reducing waste.

Reduce energy consumption

For example, industrial robots can increase production efficiency while reducing energy consumption, thereby reducing overall operating costs. This increase in energy efficiency makes robots more cost-effective in long-term operations.

Furthermore, the advantages of robots in reducing energy consumption and improving production efficiency have also brought significant economic benefits to enterprises.

Die casting robot advantages in casting machines application including improve production efficiency and product quality, reduces labor intensity and production costs. It also brings significant economic benefits and competitive advantages to enterprises. These advantages make industrial robots an indispensable and important tool in the modern casting industry.