The advantages of mould temperature controller include improved surface quality, enhanced structural integrity, and increased production efficiency.

In high-pressure die-casting production, the mold temperature is directly related to whether the casting is qualified, whether the production can be carried out efficiently, and how long the mold can be used.

The operator needs to accurately maintain the thermal balance of the mold through the mold temperature controller (mold temperature controller for short), which is crucial to ensure the stability of the die-casting process.

This article will analyze the working principle, main functions and technical value of this type of equipment in combination with actual industry applications.

Working principle and technological evolution of mold temperature controller

Mold temperature controller is a temperature control device with integrated heating and cooling functions. It realizes heat exchange by circulating heat-conducting medium (water or oil) inside the mold:

- Heating process: electric energy/gas energy → heater → heat-conducting medium → mold heating.

- Cooling process: mold heat → cooling medium (water/air) → heat discharge.

- Closed-loop control: temperature sensor real-time monitoring, PID algorithm dynamically adjusts power, and the accuracy can reach ±0.1℃.

Technological evolution:

- In the early days, it was only used for injection molds, and now it has expanded to die casting, rubber, chemical industry and other fields.

- Intelligent upgrade: microcomputer touch control, PROFINET communication interface to achieve coordinated control with die casting machine.

Advantages of Mould temperature controller

- Significantly improve casting quality

- Extend mold life by more than 30%

- Improve production efficiency by 20%-30%

- Energy saving and environmental protection benefits

- Intelligent and automated integration

Significantly improve casting quality

- Eliminate defects: Uneven temperature can cause defects such as cold shut, flow marks, bubbles, shrinkage holes, etc. The mold temperature controller controls the temperature difference within ±1°C to ensure smooth filling of the metal liquid flow.

- Case: In aluminum alloy die casting, mold temperature below 180°C is prone to flow marks; above 270°C is prone to mold sticking and thermal cracks.

- Optimize internal structure: Stabilize the temperature field to promote sequential solidification, reduce internal porosity, and improve the density and mechanical properties of castings.

Extend mold life by more than 30%

- Preheating protection: Preheat the mold evenly before production to avoid sudden contact of cold mold with high-temperature molten metal to cause thermal cracks.

- Reduce thermal stress: Constant temperature delays thermal fatigue of the mold surface and inhibits the expansion of thermal cracks.

- Reduce the risk of mold sticking: Accurate temperature control reduces the amount of release agent and avoids damage to the mold caused by alloy adhesion.

Improve production efficiency by 20%-30%

- Shorten cycle: accelerate the cooling process (such as spot cooling technology), reduce pressure holding and cooling time.

- Stabilize the beat: eliminate the filling time and spraying time variation caused by temperature fluctuations, and ensure continuous production.

Energy saving and environmental protection benefits

- Energy consumption optimization: PID algorithm outputs power on demand, saving 15%-20% energy compared to traditional heating.

- Resource conservation: reduce cooling water consumption by 30% and reduce mold release agent dosage by 40%.

Intelligent and automated integration

- Multi-zone independent temperature control: large die-casting molds are equipped with 20-40 sets of independent temperature control circuits to cope with complex structures.

- Data linkage: Link with die-casting machine parameters to adjust the process in real time (such as micro-spraying trigger).

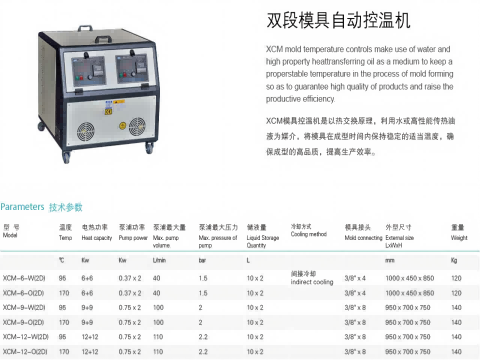

Key technical parameters of die-casting mold temperature controller

According to national standards and industry practices, the mold temperature controller must meet the following requirements:

| Parameters | Water circulation mold temperature controller | Oil circulation mold temperature controller | Application scenario |

| Temperature control range | ≤180℃ | ≤320℃ | High-temperature die casting of aluminum alloy/magnesium alloy |

| Temperature control accuracy | ±1℃ | ±1℃ | High-precision castings |

| Working pressure | ≤1.0MPa | ≤1.0MPa | Ensure system safety |

| Flow requirement | ≥80 L/min | ≥80 L/min | Large integrated die casting |

Haichen-Mold Temperature Controller

At Haichen, we integrate advanced mold temperature controllers into our die casting machines.

This system can precisely control the mold temperature to create ideal working conditions for each die casting cycle, thereby producing more consistent quality products.

It also ensures that all parts of the mold are heated evenly. This is crucial to ensure that the final product is dimensional accurate and has fewer defects

HAICHEN Mold Temperature Controllers: Integrated Innovation and Superior Performance

As a provider of comprehensive die-casting solutions, HAICHEN deeply integrates its advanced mold temperature control system into its die-casting equipment, surpassing the functionality of independent temperature control devices and achieving a comprehensive improvement in performance, efficiency, and reliability.

Intelligent Collaboration and Precise Control

HAICHEN mold temperature controllers do not operate in isolation but are seamlessly integrated with the die-casting machine’s main control system via a high-speed data bus. This deep integration brings key advantages:

Process Parameter Linkage: The mold temperature can be dynamically fine-tuned based on real-time injection curves, alloy type, and part geometry. For example, after injection, the system can immediately initiate enhanced cooling for thick-walled areas, and then precisely preheat to the ideal temperature before the next cycle, ensuring process consistency.

Multi-Zone Independent High-Precision Temperature Control: For large or complex molds (such as integrated die-cast body parts), HAICHEN provides up to 40 or more independent temperature control loops. Each circuit employs a high-precision PID algorithm and adaptive control technology to ensure that the temperature difference across all areas of the mold surface is strictly controlled within ±1°C, fundamentally eliminating defects such as flow marks, cold shuts, or localized overheating and sticking caused by uneven temperature.

Energy Efficiency Optimization and Sustainable Production

Haichen mold temperature controllers incorporate green manufacturing concepts from the initial design stage:

On-Demand Energy Supply and Heat Recovery: The system can adjust heating and cooling power output in real time according to the actual heat load of the mold, avoiding energy waste. Some high-end models also integrate waste heat recovery functionality, which can use the heat removed during cooling for preheating chilled water or auxiliary workshop heating, reducing overall energy consumption by 15%-20% compared to traditional systems.

Resource Conservation: Precise temperature control reduces reliance on external cooling water and the amount of release agent sprayed, achieving savings in water resources and chemical auxiliaries.

Using a die-casting mold temperature controller can actually solve several key problems in production. It can help workers make better products more stably and reduce pores, cold lines or cracks on the surface of castings. With a stable equipment temperature, the production rhythm can also be accelerated, and there is no need to frequently stop and adjust the mold due to inappropriate mold temperature, so there will naturally be less scrap and wasted materials.

More importantly, this precise temperature control can effectively protect the mold, avoid crack damage caused by hot and cold, and allow expensive equipment to last longer. At the same time, the entire production process is also smoother and more energy-efficient.