Aluminium road stud production line includes material preparation, designing molds, making mold, melting metal casting,feeding, injection process, cooling molding, demolding, and other steps.

The material of aluminum road studs is usually aluminum alloy. These can be pressure cast from aluminum alloy and usually measure 100mm x 100mm with a height of 20mm and an optional anchor bolt length of 50mm.

Aluminum road studs are available in a variety of types, including those with lenses, those with anchor pins, and those with spikes. These road studs play an important role in road safety by demarcating road boundaries, and improving night visibility and reducing traffic accidents.

Aluminium road stud production line

- Material preparation

- Designing and making road stud mould

- Melting the aluminum

- Feeding process

- Injection process

- Cooling solidification

- Trimming and surface treatment

- Shot peening

- Cleaning and Packaging

Material preparation

Aluminum road studs typically use aluminum alloy as the raw material due to its durability.

Designing and making road stud mould

First of all, we should design and manufacture the mold based on the shape and dimensional accuracy required for the aluminum road stud product.

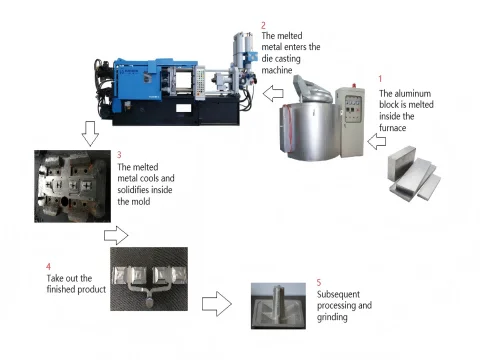

Melting the aluminum

Workers ladle molten aluminum from a separate furnace into the cold chamber of the casting machine.

Feeding process

The automated ladle the appropriate weight of molten aluminum alloy material from the furnace for each road stud production run and pours it into the inlet of the die casting machine’s press chamber.

Injection process

In the press chamber, the hydraulic system pushes the molten metal into the cavity of the road stud mould through a piston.

In this process, the injection punch advances, hydraulically inserts the metal into the mould cavity. And injects the molten aluminum alloy into the mould cavity through a concentrated inlet through high pressure.

Cooling solidification

Molten aluminum begins to cool and solidify the shape of the molded cavity immediately upon contact with the inner surface of the mold.

Control of the cooling time is critical to ensure uniform solidification of the aluminum. It can prevent defects such as warpage or internal porosity.

Trimming and surface treatment

Die castings deburred, rounded, and descaled to remove rust and rust. Decorative surface treatments to improve functional edges and surface appearance.

Shot peening

Ability to clean purposefully and where it is needed.

Adjusted the angle of the gun and the spraying distance to the optimum position at any time according to the operator’s observation.

Cleaning and Packaging

Cleaning products directly or indirectly affect liquids and dirt, dispersing, emulsifying agents, and stripping the dirt layer for cleaning purposes..

So After the finished product comes out, packing to prevent damage to the finished product.

The size of the road studs

Road studs: The specifications are generally 100mm×100mm×20mm, and the height is not more than 25mm. The specifications of reflective road studs are also usually 100mm×100mm×20mm, and the height is not more than 25mm.

Railway Road Studs: Road studs include 8mm× 80mm, 10mm× 100mm, 12mm× 120mm, 14mm× 130mm, 16mm×165mm, etc. Other sizes include road studs with a diameter of 8 to 10 mm and a length of 30 to 75 mm. The diameter of the spiral road nail is generally 3.0mm to 5.5mm, and the length is adjusted according to the need.

Special types of road nails: Some special types of road nails, such as doghead road nails, are specified as a nail bar length of 165mm, a cross-section of 16mm × a rectangular nail bar.

The size of the LED four-sided illuminated buried road stud is D138mm×H66mm, and the protruding ground height is only 15mm.

To sum up, the size of road studs varies according to different uses and types. It mainly including road studs and railway studs, among which the specifications of railway road studs are more diverse.

What machine can produce Aluminium road stud?

Cold chamber die casting machine can produce aluminium road stud.

Aluminum alloy die casting is an industrial process that uses high pressure to inject molten metal into a mold cavity to form parts. This process is in a cold chamber or hot chamber die casting machine, among which cold chamber die casting machines are more common because the melting point of aluminum alloys is lower, which is suitable for high pressure operation.

What are road studs made of?

Road studs can be made from a wide variety of metals but are most commonly manufactured in stainless steel and aluminium. The majority of road studs that pedestrians will come across will be aluminium due to their high strength, corrosion resistance and long life.

Haichen aluminium road stud cold chamber die casting machine

Haichen is a die casting machine factory located in Ningbo, China, mainly supplying cold chamber die casting machine and hot chamber die casting machine. Besides machines, we also supply die casting auxiliary equipments, including temperature control equipment, ladles and extractors and so on.

We have rich experience and cases in producing aluminum road studs. So we can provide a complete production line. We supply aluminum alloy road stud cold chamber die casting machine, molds and corresponding auxiliary machines. Welcome to consult us and choose us as your aluminum alloy spike manufacturer.

Therefore, this aluminium road stud production line ensures high precision and quality of aluminum alloy die castings.