Aluminum alloy die casting mold is a key tool used to fill molten metal at high pressure and high speed to manufacture complex parts.

Accurate aluminum alloy die-casting mold design and process optimization directly affect product quality and production efficiency.

If you are looking to learn about the aluminum alloy die casting industry and molds, you have come to the right place. Haichen has been working in the die casting field for more than 20 years and has rich practical experience. Let us list the technical information of aluminum alloy die casting molds for you.

Mold knowledge in aluminum alloy die casting technology

- Materials and Coating Technologies

- Mold Design and Structure

- Process Parameters and Quality Control

- Surface Treatment and Alloy Modification

- Advanced Technologies and Applications

- Cost Efficiency and Productivity

Materials and Coating Technologies

- Corrosion- and Wear-Resistant Coatings: Feng Zongjian (2012) developed ZrB2-Co composite coatings using laser cladding. These coatings bond metallurgically with the mold substrate, enhancing corrosion resistance, thermal fatigue resistance, and wear resistance while preventing thermal cycling cracks.

- Mold Substrate Materials: Manufacturers typically use special cast iron or steel (e.g., H13 steel) for molds to withstand high pressure and temperatures. Permanent molds require materials with high thermal conductivity, and engineers often apply graphite coatings to cavity surfaces to extend lifespan and simplify demolding.

Mold Design and Structure

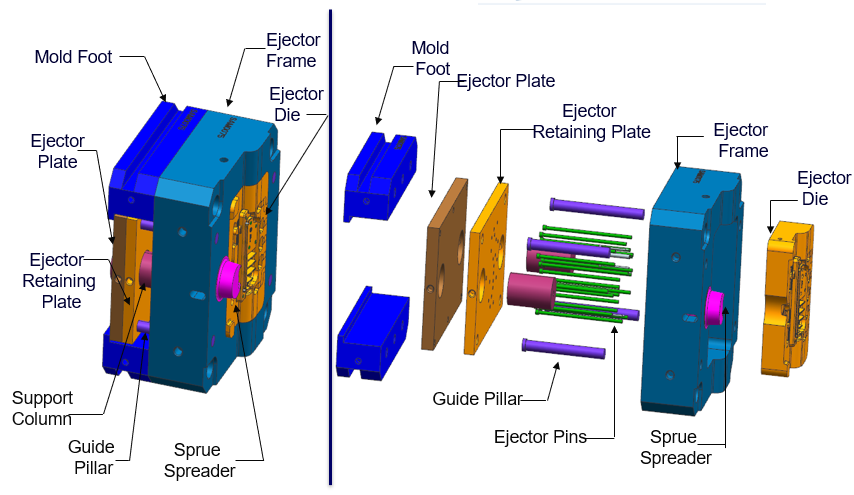

- Core Components: An Aluminum alloy die casting mold ntegrates a fixed die (Cover Die) and movable die (Ejector Die), featuring a gating system (runner, sprue), cavity, and ejector pins. Critical components include cavity inserts and cooling channels.

- Complex Geometry Optimization: For thin-walled parts (e.g., medical gloves), engineers combine semi-solid die-casting with resin sand cores and simulate filling processes to eliminate weld lines and forming defects.

Process Parameters and Quality Control

- Temperature Control: Operators maintain mold temperatures at 230–280°C (~40% of molten aluminum temperature) using oil-based heating/cooling systems. For example, a transmission housing mold operates at 200°C (fixed die) and 220°C (movable die) to reduce thermal stress and improve density.

- Injection Parameter Optimization: Studies demonstrate that delaying the high-to-low-speed switch and optimizing gate speeds (e.g., 48 m/s) minimize end-of-fill defects, achieving 220 MPa tensile strength and 8% elongation. High pressure (5–150 MPa) and speed (5–100 m/s) drive die-casting efficiency.

Surface Treatment and Alloy Modification

- Alloy Modification: Al-Si alloys (e.g., A380, ADC12) dominate due to their fluidity and corrosion resistance. Adding Sr or Na refines silicon phases, boosting elongation by 55%. Engineers use phosphorus modification to suppress silicon precipitation in hypereutectic Al-Si alloys.

- Lubrication and Demolding: Manufacturers apply high-temperature lubricants (low volatility, non-corrosive) to molds to prevent sticking and residue.

Advanced Technologies and Applications

- Semi-Solid Die-Casting: This method enables precision forming of thin-walled parts (e.g., medical gloves) via uniform acceleration barrel incubation and simulation-guided parameter tuning.

- Large-Scale Molds: Chongqing Dongke Mold produces 1,600-ton molds for EV drive housings and telecom heat sinks. Research explores 60,000 kN presses for integrated vehicle body casting.

Cost Efficiency and Productivity

- High Volume and Low Cost: Molds withstand millions of cycles, while optimized gating systems and reduced machining (e.g., Hanway’s heat treatment) cut costs.

Key technologies for aluminum die-casting molds include heat-resistant steels, composite coatings, optimized gating systems, and precise control of temperature/pressure/speed.

Future trends prioritize larger-tonnage molds, real-time process simulation.

And recyclable materials to meet demands for lightweight, high-precision parts in EVs and aerospace.

How to make a die casting mould?

Die casting mold manufacturing is a complex and precision-driven process that integrates design, material selection, machining, and testing. Below is a detailed breakdown of the key steps and technical considerations:

- Mold Design

- Material Selection

- Machining Processes

- Heat Treatment & Stress Relief

- Mold Assembly

- Trial & Adjustment

- Mold Maintenance

Mold Design

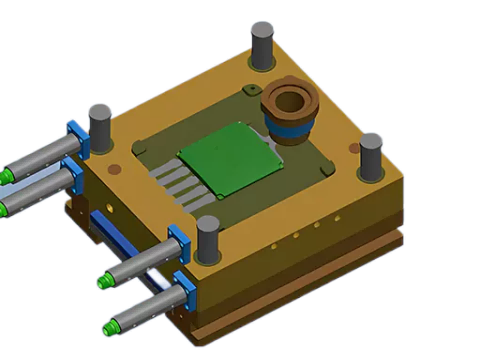

- CAD Modeling: Create a 3D model based on part specifications, defining critical structures like parting lines, gating systems, ejection mechanisms, and cooling channels. Design considerations include metal flow dynamics, venting, and thermal management.

- Simulation Analysis: Use CAE software (e.g., Moldflow) to simulate filling, solidification, and potential defects (e.g., porosity, shrinkage). Optimize gate locations and cooling layouts iteratively.

Material Selection

- Tool Steel: The mold base is typically made of heat-resistant, high-strength steel such as H13, SKD61, or DIN 1.2343. Heat treatment (HRC 48-52) ensures resistance to thermal fatigue and high-pressure stress.

- Critical Components: Cores, sliders, and ejector pins may use tungsten carbide or surface coatings (e.g., TiN, CrN) to enhance wear resistance.

Machining Processes

- CNC Roughing: Mill and drill the mold base, leaving allowances for finishing. Deep cavities require extended-reach tooling.

- Precision Machining:

- EDM (Electrical Discharge Machining): For intricate geometries or fine surface textures.

- Jig Boring: Achieve high-precision alignment of guide pins and inserts.

- High-Speed Milling (HSM): Use ball-end mills for smooth surface finishes (Ra ≤ 0.8μm).

- Polishing & Surface Treatment: Hand-polish cavities to mirror-like finishes (e.g., VDI 18). Apply nitriding or PVD coatings for durability.

Heat Treatment & Stress Relief

- Stress Relieving: Anneal at 500–600°C after rough machining to minimize distortion.

- Hardening: Vacuum quench for uniform hardness, followed by tempering (e.g., H13 steel: double-tempered at 550°C).

Mold Assembly

- Guiding System: Install guide pillars/bushings with 0.01–0.02mm clearance for precise alignment.

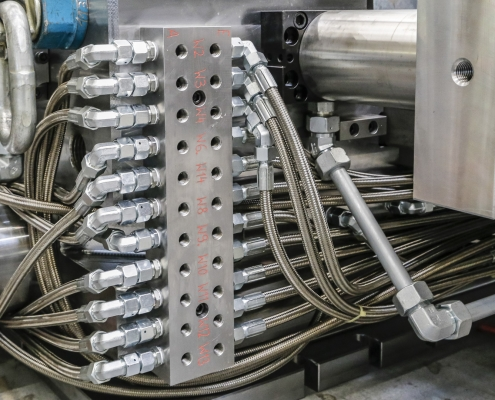

- Cooling System: Embed conformal cooling channels (copper pipes or 3D-printed designs). Pressure-test for leaks.

- Ejection System: Set ejector pins, return springs, and ensure stroke exceeds part height by 2–3mm.

Trial & Adjustment

- Process Optimization: Adjust parameters based on alloy type (e.g., aluminum alloy ADC12):

- Injection pressure: 60–90 MPa (cold chamber machines).

- Mold temperature: 180–250°C (aluminum).

- Dwell time: 3–10 seconds (depending on wall thickness).

- Defect Correction: Modify overflow wells, venting slots, or gate cross-sections to address porosity, warping, or incomplete filling.

Mold Maintenance

- Routine Checks: Inspect lubrication, wear, and alignment every 5,000 cycles. Clean cavities with specialized solvents.

- Repairs: Use laser cladding or TIG welding to restore worn areas, followed by repolishing.

Key Innovations

- Conformal Cooling: 3D-printed internal channels improve cooling efficiency by 40%+, reducing cycle times.

- Smart Molds: Integrated sensors monitor real-time temperature/pressure for closed-loop process control.

Aluminum Die casting molds require meticulous integration of design, materials, and precision machining. A typical mold lifespan ranges from 100,000 to 500,000 cycles, with development cycles spanning 3–6 months for complex parts (e.g., automotive housings). Mastery of thermal management and wear resistance is critical for high-volume production.

Working process of aluminum alloy die-casting mold

The aluminum alloy die-casting process is a highly precise and automated cycle, involving the following key steps and technical considerations:

- Mold Preparation and Preheating

- Clamping and Locking

- Molten Metal Injection and High-Pressure Filling

- Pressure Holding and Cooling

- Mold Opening and Ejection

- Post-Processing and Mold Maintenance

- Cycle Reset

Mold Preparation and Preheating

- Preheating: Heat the mold to 200–300°C to minimize thermal stress and extend mold life (temperature varies based on part thickness and alloy type).

- Release Agent Coating: Apply a release agent (e.g., graphite or silicone-based) to the mold cavity to prevent metal adhesion and aid demolding.

- Mold Installation: Secure the fixed and moving mold halves onto the die-casting machine, ensuring precise alignment.

Clamping and Locking

- The hydraulic system closes the mold halves to form a sealed cavity. Clamping force (typically hundreds to thousands of tons) is calculated based on part projection area and injection pressure.

Molten Metal Injection and High-Pressure Filling

- Molten Alloy Parameters: Aluminum melt temperature is maintained at 680–750°C, with vacuum degassing to remove gas impurities.

- Injection Stages: The injection plunger forces molten metal into the cavity at high pressure (10–100+ MPa) and high speed (16–80 m/s), completing filling in 0.01–0.02 seconds.

- Filling Dynamics: Metal flows in three phases: initial shell formation along cavity walls, core filling, and final solidification under pressure.

Pressure Holding and Cooling

- Pressure Holding: Maintain pressure for 2–5 seconds post-filling to minimize shrinkage and porosity.

- Cooling Control: Use built-in water/air channels to accelerate solidification. Cooling time (5–15 seconds) depends on wall thickness; improper cooling leads to warping or defects.

Mold Opening and Ejection

- Separate mold halves to a preset opening distance (e.g., 400 mm). Ejector pins or hydraulic cylinders push out the casting (e.g., 40 mm stroke), along with overflow and biscuit residues.

- Automated robots or operators remove the part to avoid surface damage.

Post-Processing and Mold Maintenance

- Casting Finishing: Remove flash, burrs, and gates via trimming, shot blasting, or polishing.

- Mold Cleaning and Cooling: Spray coolant to lower mold temperature and remove residual release agent/aluminum debris.

- Mold Inspection: Check for thermal fatigue cracks, wear, etc. Molds typically require repair/replacement after 20,000–50,000 cycles.

Cycle Reset

- Close the mold, reapply release agent, and preheat for the next cycle.

Critical Technical Factors:

- Temperature Control: Melt, mold, and cooling rates directly affect part quality and surface finish.

- Pressure-Speed Optimization: Balance pressure and injection speed to avoid air entrapment or incomplete filling (simulation software is often used).

- Automation: Robotic handling and real-time monitoring ensure efficiency and consistency.

Key Considerations:

- Melt temperatures vary across literature (e.g., 700°C vs. 750°C), depending on alloy composition (e.g., ADC12 vs. A380).

- Mold preheating temperature adjustments are critical for complex geometries.

In summary, aluminum die-casting is a tightly controlled thermo-mechanical process requiring multi-stage coordination to achieve high-quality production.

Haichen’s die-casting molds excel in precision engineering, material adaptability, and intelligent maintenance, working in conjunction with high-efficiency discharge control equipment and stable hydraulic systems. These capabilities provide robust, reliable, and high-quality production results for the automotive, home appliance, and hardware industries.