Aluminum alloys are widely used in the High – Pressure Die Casting (HPDC) process due to their excellent flow characteristics, low melting point, and high strength – to – weight ratio, making them ideal for producing complex and lightweight parts efficiently.

Aluminum alloys play a crucial role in the High Pressure Die Casting (HPDC) process due to their unique combination of properties that make them ideal for producing high-quality, lightweight, and durable components.

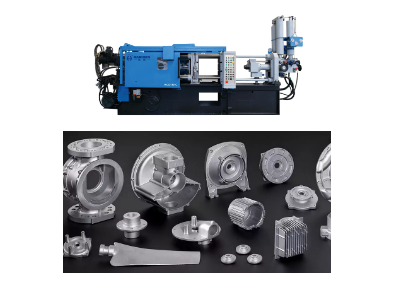

Automotive, aerospace and consumer electronics manufacturers widely adopt the HPDC process to mass-produce precision components with tight tolerances.

This article will explore the characteristics of aluminum alloys and how they interact with the HPDC process to achieve optimal results.

Characteristics of Aluminum Alloys

Aluminum alloys are engineered materials designed to offer a balance of strength, weight, and corrosion resistance. Key characteristics include:

- Lightweight: Aluminum alloys are significantly lighter than traditional materials like steel. Making them ideal for applications where weight reduction is critical.

- High Strength: Despite their low weight, aluminum alloys can achieve high strength levels, often comparable to those of steel.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing excellent resistance to corrosion.

- Thermal Conductivity: Aluminum has high thermal conductivity, which is beneficial for heat dissipation in applications such as engine parts and electronics.

Haichen Practice and Expansion:

Haichen possesses extensive experience in die-casting aluminum alloy applications. Our HPDC series die-casting machines are optimized to fully utilize the properties of aluminum alloys.

- Regarding flowability: Our machines’ precise injection control system matches the optimal filling speed curve for different aluminum alloys, ensuring uniform filling of the deep cavity in complex parts such as 280×70 aluminum deep frying pans.

- Regarding strength and lightweight: We collaborate with customers to select suitable aluminum alloy grades for applications such as automotive structural components, and further improve the density and mechanical properties of castings through process optimization (such as high vacuum technology).

- Regarding thermal management: Our intelligent mold temperature control system precisely regulates the solidification process of aluminum alloys, reducing internal stress, which is crucial for products requiring good thermal conductivity and dimensional stability, such as 5G base station heat sinks.

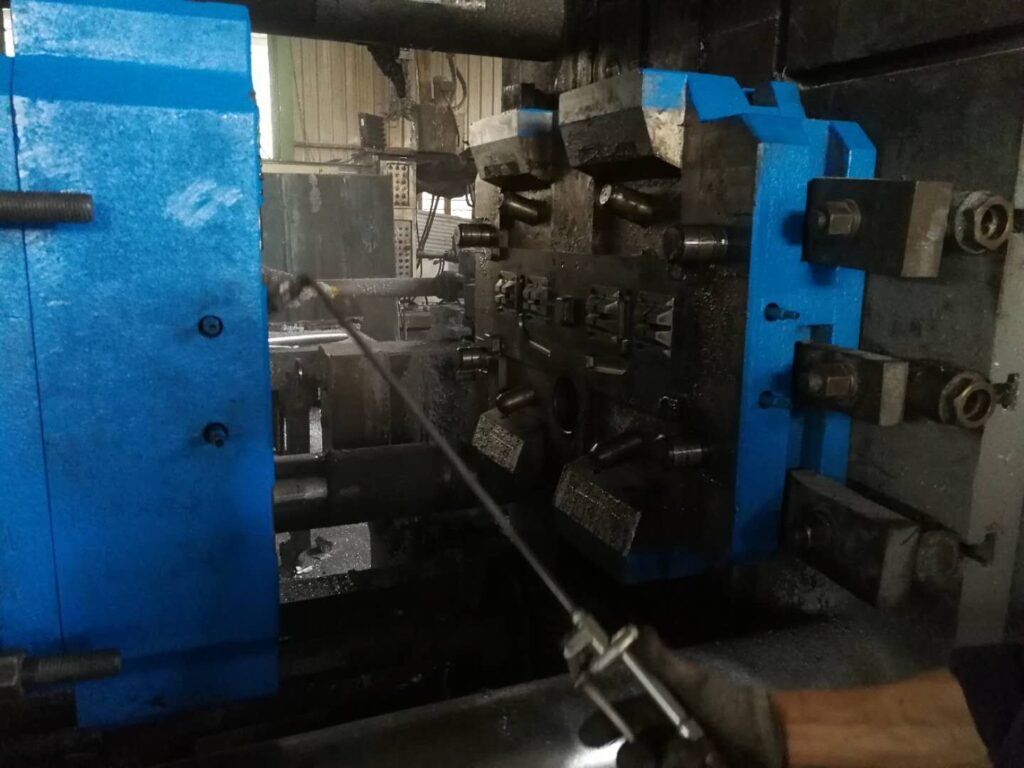

HPDC Process Overview

The High Pressure Die Casting process involves injecting molten aluminum alloy into a steel mold (die) at high speed and under high pressure. The process is characterized by:

- High Injection Speed: The injection system drives molten metal at 2-8 m/s velocities to fill mold cavities within 50-100 milliseconds.

- High Pressure: The injection system applies pressures up to 900 bar to completely fill mold cavities and achieve uniform solidification.

- Rapid Cooling: The metal solidifies quickly in the mold, resulting in fine-grained microstructures and high mechanical properties.

- Automation: Advanced automation drives this process, achieving 800+ cycles/hour with ≤0.1% quality variation across production batches.

Interaction of Aluminum Alloys with HPDC

The success of the HPDC process relies heavily on the compatibility of the aluminum alloy with the casting conditions. Key factors include:

- Flowability: Aluminum alloys must have good flow properties to fill complex mold designs without defects.

- Solidification Rate: Process engineers optimize the alloy’s solidification rate to eliminate porosity and shrinkage defects in castings.

- Thermal Stability: The alloy must withstand the thermal stresses of the HPDC process without degrading.

- Mold Compatibility: The alloy must not chemically react with the mold material, ensuring long mold life and consistent part quality.

Real – World Applications

The combination of aluminum alloys and the HPDC process is us in a wide range of industries:

- Automotive

- Aerospace

- Consumer Electronics

Automotive

In the automotive industry, HPDC is use to produce lightweight components such as engine blocks, transmission housings, and wheel hubs. The use of aluminum alloys reduces vehicle weight, improving fuel efficiency and performance.

Aerospace

The aerospace industry benefits from the high strength – to – weight ratio of aluminum alloys, using HPDC to produce parts such as aircraft structural components and engine parts. The precision and consistency of the HPDC process ensure that these parts meet stringent quality standards.

Consumer Electronics

The consumer electronics industry relies on HPDC to produce lightweight, durable, and aesthetically pleasing parts. Aluminum alloys are used in the production of laptop casings, smartphone frames, and other electronic components.

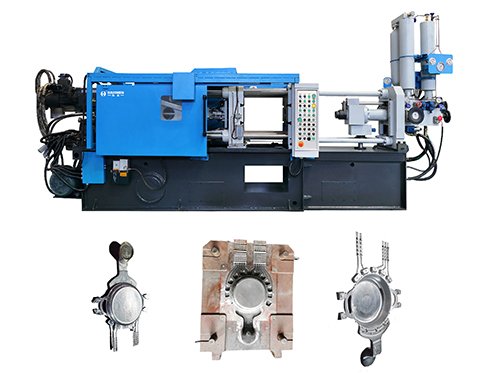

HAICHEN Aluminum Alloy Die Casting Practice Case

HAICHEN has extensive experience in aluminum alloy die casting. Our equipment performance and process solutions are deeply match to the properties of aluminum alloys to address core challenges in production.

Case: Efficient Production of Large, Thin-Wall Aluminum Fry Pan

A cookware manufacturer needed to produce an aluminum fry pan with a diameter of 280mm and height of 70mm. The product had thin walls (4mm bottom, 2.8mm side) and required a smooth surface finish and fast cycle time.

- Challenge: The thin-wall, deep-cavity structure demanded extremely high metal filling speed and balanced mold temperature, with risks of cold shuts or incomplete filling.

- HAICHEN Solution: A HAICHEN 650-ton cold chamber die casting machine was used with targeted process optimization.

- Filling Control: The servo injection system executed a “slow-fast-slow” multi-stage speed profile to ensure smooth and rapid cavity filling while avoiding air entrapment.

- Temperature Management: A multi-zone mold temperature controller provided precise temperature control to different mold areas, ensuring thermal balance and reducing distortion.

- Mold Coordination: The gating and venting system was optimized to promote sequential filling and effective air evacuation.

- Result: The production cycle time stabilized under 45 seconds with a product yield rate exceeding 98.5%. The casting surface quality and wall thickness uniformity fully met requirements.

HAICHEN: Your Partner in HPDC Solutions

At HAICHEN, we specialize in manufacturing advanced high-pressure die casting machines designed to work seamlessly with aluminum alloys. Our precision-engineered machines control injection speed (±0.5%), pressure (up to 2500 bar) and cooling rate (±1°C) to guarantee superior casting quality and 15-20% higher productivity. By leveraging our expertise in HPDC technology and material science, we help our customers achieve high-quality aluminum alloy castings with minimal defects and maximum production efficiency.

Why Choose HAICHEN?

- Advanced Technology: Our HPDC machines integrate advanced control systems and precision-engineered components that maintain consistent casting quality within ±0.1mm tolerances.

- Custom Solutions: We offer tailored machine configurations to meet specific production needs, including mold size, alloy type, and production volume.

- Quality and Reliability: HAICHEN manufactures machines that meet the industry’s strictest quality benchmarks, delivering reliable long-term operation with 98% uptime guarantees.

- Comprehensive Support: Our commitment to customer satisfaction includes comprehensive after-sales support, technical assistance, and maintenance services.

Aluminum alloys are essential materials in the HPDC process, offering a unique combination of properties that enable the production of high-quality, lightweight, and durable components. By understanding the characteristics of aluminum alloys and optimizing the HPDC process, manufacturers can achieve excellent casting results.