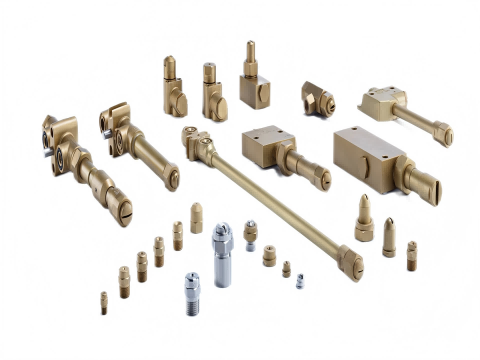

Aluminum Die Casting Connector parts are a kind of connecting parts used in aluminium alloy die casting machine.

They usually include connectors, connecting rods, ejection rod connectors and so on.

These fittings play a key role in the die casting process to ensure the normal operation of the equipment and efficient production.

Functional characteristics of aluminum die casting machine connector

Aluminium alloy die casting machine connector fittings have the following characteristics:

- Material and process

- Application Scene

- Specification and customisation

- Technical parameters

Material and process

These connector fittings are usually made of aluminium alloy material and produced by die casting process.

Aluminium alloy materials have good mechanical properties and corrosion resistance, suitable for use in industrial environments with high pressure and high temperature conditions.

Application Scene

Aluminium alloy die casting machine connector fittings are widely usingin various industrial fields, including automobile manufacturing, electronic equipment, new energy equipment and so on.

They can connect various parts of die casting machine, such as ejection rods, punches, material tubes and so on.

Specification and customisation

These connector fittings are available in a variety of specifications according to specific needs.

For example, ejector rod connector, punch connector, material tube connector and so on.

All of them can be designed and manufactured according to customers’ specific requirements.

Technical parameters

The technical parameters of some connector fittings include the material is aluminium alloy, the surface treatment is powder coating.

The colour is RAL9005 (black), the working temperature range is from -40°C to +125°C, and the protection level reaches IP65 standard.

Aluminum Die Casting Connector fittings are an important part of the die casting machine, with a variety of specifications and customization options for a wide range of industrial application scenarios.

Configure the appropriate aluminium alloy die casting machine connector design according to different die casting production requirements.

Different materials for connector fittings for aluminium die-casting machines

There are a variety of different aluminium alloy die casting machine connector fittings distributed in the various mechanical joints of the die casting machine.

Different stress parts strength needs and transmission needs decided to use different materials for aluminium alloy die casting machine connector.

Aluminum Die Casting Connector material mainly includes seven kinds:

- Aluminium alloy

- Zinc alloy

- Magnesium alloy

- Copper alloy

- Stainless steel

- Composite materials

- Other materials

Aluminium alloy

This is one of the most commonly materials, with good fluidity and corrosion resistance, suitable for manufacturing demanding parts.

Common aluminium alloy die-casting materials include ADC12, A380, A360, A390 and so on.

Zinc alloy

Zinc alloys are capable of producing die-cast machine connectors, especially in applications requiring higher strength and corrosion resistance.

Magnesium Alloy

Magnesium alloys are also using in certain transmission linkers for lightweight requirements due to their low density and high strength characteristics.

Copper alloys

Copper alloys may using in some special applications such as connectors that require electrical conductivity.

Stainless steel

In some applications requiring higher corrosion resistance and mechanical strength.

Stainless steel (such as AISI 304 or 316L) can using as a connector material.

Composite materials

For example, aluminium matrix composites (e.g. AA6082 with polyamide PA6 laminates).

This material combines the strength of an aluminium alloy with the flexibility of a polymer.

Other materials

Such as brass, nylon, etc. These materials may be used for specific connector housings or sealing elements.

Aluminium die-cast machine connector fittings are available in a wide range of material choices, and the specific material used depends on application needs, performance requirements and cost considerations.

How the aluminium die casting machine’s ejection is connected through connectors

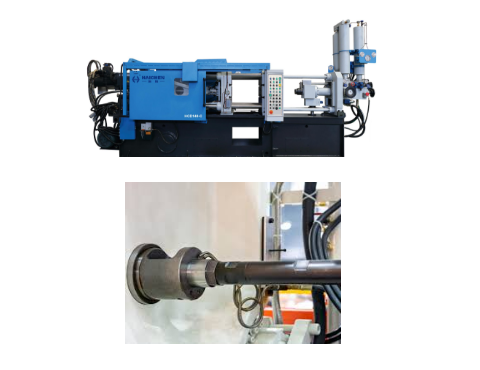

The cold chamber aluminium alloy die casting machine’s die casting system is connecting by several connectors and components.

To ensure the stability and efficiency of the die injection process.

The following is a detailed description of the connections and related components of the die injection section of a cold chamber die casting machine:

- Connection of the die-injection piston with the booster piston rod

- Pressure injection cylinder and booster cylinder connection

- The connection of pressure injection punch cooling device:

- Connection of the pressure ejection rod and the pressure ejection hammer head

- Other connectors

Connection of the die-injection piston with the booster piston rod

The connection between the press injection piston and the booster piston rod is made by means of a floating piston.

The improved floating piston connection structure designs the connection body and the booster piston rod as one piece.

The front end of the booster piston rod is provided with a thread, which is screwed to the front end of the booster piston rod by a connecting nut.

At the same time, a cotter pin is using to prevent the nut from loosening, thus ensuring the stability of the connection.

Pressure injection cylinder and booster cylinder connection

Cold chamber die casting machine adopts the structural form of tandem connection of pressure injection cylinder and booster cylinder.

Through the hydraulic system to the pressure injection cylinder sealing oil pressure for boosting, in order to meet the requirements of large pressure injection force.

This design can effectively improve the stability of the system and process efficiency.

The connection of pressure injection punch cooling device

In the horizontal cold chamber die casting machine, the connection of the cooling device of the pressure injection punch is realising through the first connection pipe and the second connection pipe.

The first connecting pipe is fixedly connected to the annular water-cooled bin, and the second connecting pipe is connected to the first connecting pipe by means of a threaded bushing.

Cooling water is introducing into the annular water-cooled compartment through these tubes to achieve effective cooling of the press-fired punch.

Connection of the pressure ejection rod and the pressure ejection hammer head

The ejector rod and the ejector hammer head are usually connected by threads to form a rigid rod.

It ensures that both can move synchronously during the pressure injection process.

This design contributes to the overall stability and longevity of the press shot system.

Other connectors

The pressure injection part of the cold chamber die casting machine also includes a variety of connecting parts, such as the pressure injection valve plate, pressure injection reservoir, quick-exit inserts and valve plate.

These parts are connecting to each other through bolts, inserts and solenoid valves, etc. to ensure the coordinated operation of the whole die injection system.

The cold chamber aluminium alloy die casting machine’s pressure injection system achieves a highly efficient and stable pressure injection process through the precise coordination of a variety of connectors and components.

These connections not only improve the reliability of the system, but also optimise the process and enhance product quality.

Precision connectors for Haichen aluminium die-casting machines

Haichen produces cold chamber die casting machines aluminium connectors (such as the HCD series) with highly sophisticated design and manufacturing processes.

Our die casting machines use computer-aided design (CAD/CAE) and finite element analysis technology to ensure the performance and reliability of key components.

In addition, the hydraulic and electrical systems of Haichen die casting machines use components from well-known European, American and Japanese brands to ensure the safety and reliability of the equipment.

In terms of precision Aluminum Die Casting Connector, the control system of Haichen die casting machine adopts Siemens PLC.

It also has a multi-language interface and module number storage function, which can store the parameter settings of multiple moulds.

This precision control system helps to realise high-precision production requirements, especially where fine control of injection position and pressure is required.

Haichen die casting machines are also equipped with advanced hydraulic systems.

A proportional control system is used to achieve multi-stage pressure and speed control, which ensures the stability and efficiency of the injection process.

These features make Haichen aluminium alloy die casting machine perform well in manufacturing all kinds of precise and complex parts.

Welcome to leave your message for more details, let us serve you wholeheartedly.