Aluminum Die Casting for Crankcases includes material selection and performance, die casting process, Design and Optimization and so on.

Aluminum die-cast crankcases have become the core components of modern engine design due to their lightweight, high strength and ability to achieve complex geometry. The continuous optimization of its manufacturing process and innovation in material science will further promote its application in automobiles, motorcycles and emerging fields.

The optimization of aluminum alloy crankcase die-casting process needs to be based on material properties, combined with mold design, process parameters and defect control, and high-quality production can be achieved through CAE simulation and experimental verification. Select suitable alloys and processes for different application scenarios (such as motorcycles and agricultural machinery), while paying attention to the balance between cost and efficiency, and ultimately achieve high-performance, low-cost die-casting solutions.

The application of aluminum die casting in crankcase manufacturing has significant advantages and a wide range of applications.

Material selection and performance of aluminum die casting for crankcases

Aluminum alloys are ideal materials for crankcase manufacturing due to their light weight, high strength and good corrosion resistance. AS41A alloy (containing 4% aluminum and 1% silicon) has better creep strength at high temperatures than other magnesium alloy die-casting materials. And it has good elongation, yield strength and tensile strength. So it widely uses in crankcases of air-cooled automobile engines.

A380/A383

A380 (ADC10) is widely used in ordinary motorcycle engine crankcases due to its good fluidity and low cost, while A383 (ADC12) is suitable for complex structural parts due to its excellent mold life and thermal cracking resistance.

A356-T6

After T6 heat treatment, its tensile strength can reach 290-330 MPa, suitable for high-performance engines (such as Ducati Panigale).

AS41B/AS41A

Alloys containing 4% silicon show excellent high-temperature creep resistance in air-cooled engines and are suitable for lightweight design.

High-purity aluminum alloys (such as A356) are also commonly used in crankcase manufacturing. Their excellent mechanical properties and microstructure further improve through improved processes (such as direct water cooling).

Core performance advantages of aluminum die casting crankcases

Balance of lightness and strength

The density of aluminum (2.7 g/cm³) is significantly lower than that of cast iron (7.8 g/cm³), while alloying (such as adding copper and magnesium) improves strength to meet high power density requirements.

Thermal management capabilities

The thermal conductivity of aluminum (96-120 W/m·K) can effectively dissipate engine heat and prevent overheating.

Complex geometry realization

High-pressure die casting (HPDC) process supports one-piece design, reducing the number of parts and lowering assembly costs.

Die casting process of aluminum die casting for crankcases

Aluminum die casting is an efficient and precise manufacturing process that uses high pressure to inject molten aluminum into a prefabricated mold, rapidly cools and solidifies to form parts. This process is particularly suitable for producing thin-walled, complex-shaped parts.

Vacuum-assisted die casting

Reduce porosity (<1%) by vacuuming to ensure tightness

Heat treatment

T6 treatment (solid solution + aging) significantly improves the hardness and fatigue life of A356-T6.

Mold design

Optimize cooling channels and rib structures to cope with thermal deformation and stress concentration

High pressure die casting (HPDC) is the most commonly uses method in aluminum die casting, capable of producing parts with high dimensional accuracy and good surface quality. In addition, low pressure die casting (LPDC) and gravity casting are also use for specific applications, such as steering knuckles.

Design and Optimization of aluminum die casting for crankcases

The design of the crankcase needs to consider its structural strength and durability. Through finite element analysis (FEA) and numerical simulation (NI), the design can optimize to improve the performance of the parts.

Complex structure optimization

Wall thickness difference: Use auxiliary ingate (such as middle diversion) to improve filling uniformity and reduce cold shut defects.

Cold shut and sticking mold

Solved by adding cooling water channels (such as surface heat dissipation network) and local pressurization (such as local boost design).

Venting and shrinkage compensation

- Design a reasonable overflow trough and exhaust system to ensure that the molten metal is fully filled and the gas is discharged.

- Low pressure casting (LPC) can reduce shrinkage and pores, especially for complex structures.

During the design process, should pay special attention to the design of the oil channel to avoid oil leakage caused by casting defects.

Manufacturing process

Aluminum die-casting molds for crankcases usually made of high-quality steel and are precision machined to ensure the dimensional accuracy of the mold.

Mold design and manufacturing are the key to the success of aluminum die casting. The application of modern mold design tools and CNC processing technology makes mold manufacturing more efficient and accurate.

Mold design and manufacturing

- Mold materials: Molds are usually made of high-hardness tool steel (such as P20, H13) or maraging steel (such as Maraging Steel) to withstand high pressure and high temperature environments. Mold design requires CAD modeling to ensure accurate replication of complex geometries, such as internal oil channels, bearing seats, and connection points.

- Mold manufacturing process: includes forging, rough machining, heat treatment (quenching + tempering), finishing (CNC milling), and surface treatment (such as plating or coating) to improve wear resistance. For example, Haichen’s cold chamber die-casting machine molds are subject to four shot pressure controls (slow shot → fast shot → boost) to optimize metal flow.

Material selection and melting

Common alloys

- A380/A383: good fluidity and high strength (tensile strength 310–330 MPa), suitable for motorcycle and automobile crankcases.

- A356-T6: After T6 treatment, the strength can reach 290 MPa, suitable for high-performance engines.

- AC9U: Contains silicon and copper, and is more resistant to high temperatures and wear than pure silicon aluminum alloys.

Melting process

- Using a cold chamber die casting machine (Cold Chamber Die Casting), molten aluminum ingots (2.7 g/cm³ density) are poured into a steel mold.

The melting temperature is controlled at 650–700°C, and the mold needs to be preheated to reduce thermal shock and ensure uniform cooling

Die casting

High pressure injection

- The die casting machine applies 7–350 MPa pressure to quickly inject molten aluminum into the mold cavity to fill complex structures (such as multi-stage oil channels and thin-walled areas)

- Vacuum-assisted die casting: Reduce porosity (<1%) by vacuuming and improve sealing.

Cooling and demolding

- The mold cooling water channel controls the cooling rate, allowing the metal to solidify quickly under high pressure to form a dense structure

- When demolding, the knockout pins are used to separate the casting to avoid sticking

Post-processing and quality control

Heat treatment

T6 treatment (solid solution + aging) enhances hardness and fatigue strength, for example, the tensile strength of A356-T6 reaches 290 MPa.

Machining

CNC machining corrects dimensional tolerances (such as bearing holes ± 0.02 mm), removes burrs and optimizes surface finish.

Surface treatment

- Coating: anodizing, powder coating or electroplating chrome to improve corrosion resistance.

- Sandblasting/polishing: remove surface defects and increase surface roughness to enhance mechanical clamping force.

Quality inspection

- X-ray inspection to check internal defects, ultrasonic cleaning to remove oil stains.

- Radio marking (laser coding) and steam atomization to ensure clear product identification.

Above all, aluminum die casting technology has significant advantages in crankcase manufacturing, which can meet the needs of modern industry for high performance, light weight and low cost. The performance and reliability of crankcases can further improve by optimizing material selection, process design and mold manufacturing.

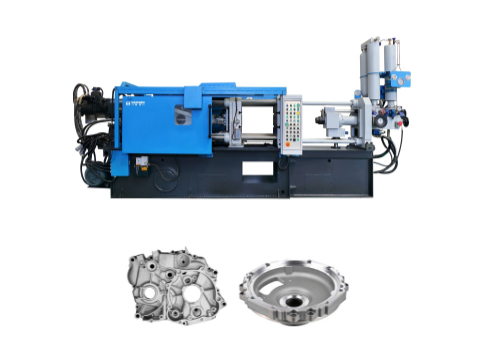

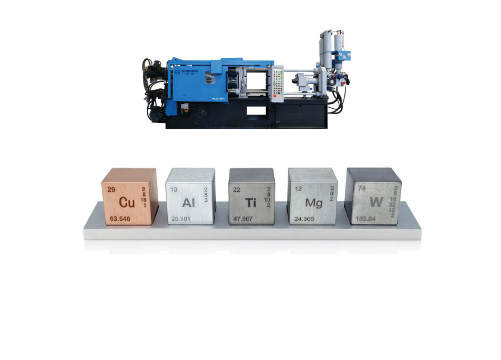

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.