An aluminum die casting furnace is equipment that melts and holds aluminum alloy for the casting process. This article will discuss its key safety features. We will explain common risks and how to prevent them. Finally, we will show the role of modern technology in creating a safe workplace.

Understanding Key Furnace Hazards

Working with molten aluminum involves specific dangers that require clear understanding.

- High Temperature and Burns

- Molten Metal Splashes

High Temperature and Burns

The furnace operates at very high temperatures, often above 660°C. Direct contact with the furnace shell, ladles, or spilled metal causes severe burns. Therefore, operators must always wear proper personal protective equipment (PPE), like heat-resistant gloves and face shields.

Molten Metal Splashes

Adding wet materials or tools into molten aluminum can cause explosive splashes. Similarly, rapid heating or stirring can lead to spills. To prevent this, all materials must be completely dry, and procedures must forbid unsafe actions near the furnace.

Essential Safety Systems and Devices

Modern furnaces include built-in systems to reduce risks and protect workers.

- Temperature and Overheat Controls

- Leak Detection and Emergency Stop

Temperature and Overheat Controls

Precise temperature controllers prevent the metal from overheating. If temperatures rise too high, an automatic alarm sounds. In addition, the system can cut power to the heating elements. This maintains safe operating conditions.

Leak Detection and Emergency Stop

Furnaces should have a sensor to detect molten metal leaks from the crucible. For instance, a sensor at the base can trigger an alert. Above all, an easy-to-reach emergency stop button allows immediate shutdown in any dangerous situation.

Safe Operation Procedures and Training

Technology alone cannot ensure safety; correct human actions are critical.

- Standardized Pre-Operation Checks

- Regular Maintenance and Staff Training

Standardized Pre-Operation Checks

Operators must follow a checklist before starting the furnace. This includes checking the crucible for cracks and ensuring all safety devices work. After that, they can begin the melting process with greater confidence.

Regular Maintenance and Staff Training

Scheduled maintenance keeps the furnace in safe condition. However, trained staff are the most important safety feature. Regular training updates everyone on hazards and correct responses to emergencies.

HAICHEN Aluminum Die Casting Furnace Safety Case

HAICHEN produce and supply furnaces with a complete safety-first philosophy:

Supporting Foundries in Serbia

HAICHEN has supplied several aluminum die casting furnace units to manufacturers in Serbia’s industrial center, such as Kruševac. These units feature robust safety configurations tailored for European safety standards. Their reliable performance in Serbian production lines demonstrates HAICHEN’s commitment to global safety.

The Role of Furnace Design in Long-Term Safety

Good safety results from thoughtful design choices made before production.

- Structural Integrity and Insulation

- Ergonomic and Protective Features

Structural Integrity and Insulation

A strong furnace structure resists deformation from constant heat. High-quality insulation minimizes external surface temperature. This protects workers from accidental contact and improves energy efficiency.

Ergonomic and Protective Features

Designs should include protective shields around openings and clear safety signage. Moreover, controls should be placed at a safe distance from the molten metal bath. These features help prevent human error.

Aluminum Die Casting Furnace Safety and Productivity

Safety measures directly support more stable and efficient production.

- Preventing Costly Stoppages

- Building a Culture of Safety

Preventing Costly Stoppages

A major safety accident can stop production for days or weeks. Effective furnace safety systems prevent such events. Therefore, they protect not only people but also production schedules and profitability.

Building a Culture of Safety

When workers trust their equipment is safe, they operate with more focus. This leads to smoother operations and fewer mistakes. In other words, a safe furnace is a foundation for a productive workshop.

HAICHEN: Delivering Safe and Reliable Melting Solutions

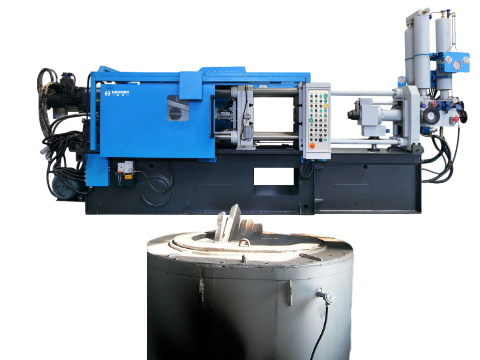

As a professional manufacturer of die casting systems, HAICHEN answers the question, “What is an aluminum die casting furnace?” with action. We build it as a core component of a safe, modern foundry. Our furnaces combine advanced safety technology with durable construction. We provide these solutions to metal product makers in China and worldwide. In conclusion, investing in a safe furnace from a trusted partner like HAICHEN protects your team and ensures the long-term success of your operation.

Aluminum Die Casting Furnace Safety supplier: Haichen Machinery

Haichen Machinery is a Chinese company specializing in the manufacturing and supply of aluminum cold chamber die casting machines, hot chamber die casting machines and related equipment.

We have rich experience in producing die casting products of different die casting materials. The furnace has many types, like electrical furnaces, gas furnaces…

We can give you professional technical support from choosing raw materials, customizing molds, and selecting molds to after-sales service.

If there is any demand for die casting machines and die casting molds, welcome to visit our website to learn the production information of different products.