Aluminum alloy road studs are used in traffic management systems to enhance road safety by providing durable, reflective markers for lane delineation, pedestrian crossings, and guiding traffic flow.

Nowadays, aluminum alloy raised road signs can be seen on many roads. They are not only strong and pressure-resistant, but also have obvious reflective effects at night. They are not easily damaged in rainy, snowy weather or environments with large temperature changes.

These raised road signs are particularly important for driving safety: at night or in low light, the reflective strips can help drivers see the lane boundaries clearly; on roads with dense traffic, they are like little guides on the ground, silently helping to sort out traffic order.

This time, let’s talk about what specific roles these small silver devices can play in different road conditions – such as how to help reduce sharp turn accidents, or why some cities choose to use them instead of traditional double yellow lines.

Application of aluminum alloy road studs

- Road Safety and Traffic Management

- Construction and Infrastructure

- Parking Lot Management

- Airport and Highway Markings

Road Safety and Traffic Management

Aluminum alloy road raised road signs play an important role in traffic safety management. We install them on highways, urban roads and parking lots to clearly indicate lane boundaries through their reflective properties. This design can provide drivers with clear road guidance, especially in low-visibility environments (such as foggy, rainy or at night), helping to reduce the risk of traffic accidents and improve the orderliness of vehicle traffic.

Construction and Infrastructure

Aluminum alloy road spikes play an important role in road construction and infrastructure. Construction teams often install these spikes on new roads and highways to clearly demarcate lanes, mark intersections and pedestrian crossings. The properties of aluminum alloy materials themselves – especially their excellent corrosion resistance and strong and durable quality. Enable these spikes to be used outdoors for a long time, even in the face of heavy rain, strong sun and other harsh weather conditions.

Parking Lot Management

In parking lot management, aluminum alloy road bumps are mainly used to demarcate parking space boundaries and guide vehicle movement. They can effectively regulate vehicle parking positions, reduce illegal road occupation, and ensure parking order. Their surface reflective properties can improve the visibility of signs at night or in low light, helping drivers to more clearly identify lane and parking space layouts.

Airport and Highway Markings

Aluminum alloy road bumps play an important role in the marking system of airports and highways. They are widely use in taxiway, runway and apron boundary markings. Providing clear navigation guidance for pilots and ground vehicle operators through high reflective properties and strong structure. These characteristics make aluminum alloy bumps a key facility for safety and security in high-traffic areas.

Technical advantages of die casting in the production of aluminum alloy road studs

Die casting is the core process for mass production of high-precision aluminum road studs. Its advantages include:

Complex structure molding capability

High-pressure injection (76-157 MPa) allows molten aluminum to quickly fill the mold, and can form complex structures such as ribbed anti-slip surfaces and deep cavity reflector slots in one go.

Production efficiency and cost control

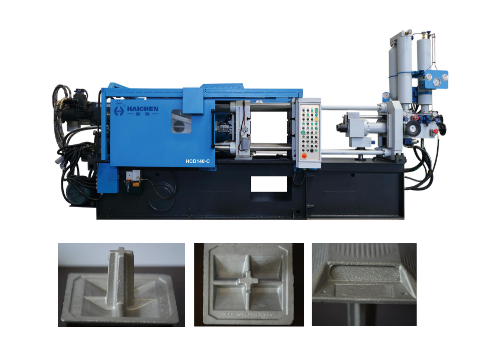

HAICHEN 4-Cavity Mould is combine with a cold chamber die casting machine. A single cycle of 50 seconds can produce 4 road studs, with a daily output of more than 5,000 pieces.

Surface quality and material utilization

The surface roughness of the die casting reaches Ra 0.8-3.2μm, without secondary processing; the material utilization rate reaches 80%, and the blank recovery rate exceeds 90%.

Technological innovation and practical cases of HAICHEN die-casting machine

Solution for efficient mass production of road studs

Equipment configuration: HCD 880-C cold chamber die-casting machine, clamping force 8800kN, suitable for 15×15cm aluminum road stud production.

Technical highlights:

- Four-stage injection control: Precisely adjust the injection speed through magnetic ruler positioning and PLC to avoid bubble defects, and the yield rate reaches 99%.

- Intelligent cooling system: Multi-channel water cooling design in the mold, combined with finite element thermodynamic analysis, shortens the cooling time by 30% and reduces thermal deformation.

- Production output: The annual production capacity of a single production line exceeds 1.8 million pieces, serving infrastructure projects in the Middle East, Southeast Asia and other regions.

Innovative technology application

- Vacuum die casting: Reduce the internal pores of road studs and increase the impact strength by 30%, suitable for severe cold areas.

- Intelligent temperature control system: Real-time monitoring of mold temperature, automatic adjustment of cooling water flow, and ensure batch consistency.

HAICHEN Machine Core Value Proposition

HAICHEN’s solution transcends simply providing a machine; it delivers a stable, turnkey production platform for road stud manufacturers.

The HCD 880-C model’s robustness ensures continuous, high-uptime operation essential for meeting tight project deadlines.

Furthermore, the deep integration of process control technologies—from injection profiling to vacuum and temperature management—transforms raw parameters into actionable process intelligence. This allows manufacturers to not only achieve exceptional quality and output today but also to digitally fine-tune and document their process for future product lines, ensuring long-term competitiveness in the global infrastructure supply chain.

Aluminum alloy road bumps are an integral part of modern road safety and traffic management systems. With their excellent reflective properties, they provide drivers with clear route guidance at night or in low light conditions; their ruggedness ensures long-term stability in withstanding vehicle crushing and harsh environments. These devices are widely use on roads, highways. And parking lots to effectively improve driving safety by clearly demarcating lanes. And warning of dangerous areas.