The application of the pressure chamber for die casting machine is mainly to improve casting quality, vacuum die-casting technology, adapt to different alloy materials, Improve production efficiency, and Special process applications.

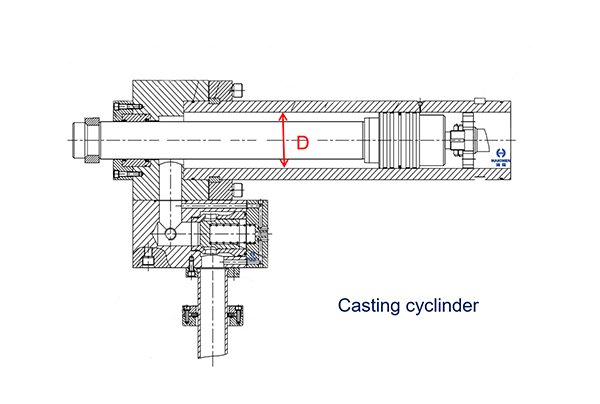

Through the integral pressure chamber cooling system, the temperature difference of the pressure chamber during the working process can be effectively reduced, the deformation of the pressure chamber can be reduced, and the service life of the pressure chamber can be increased.

The chamber/sleeve of the matel machine is a very critical part of the die casting process.

Iit’s main function is to contain the molten metal to be injected and inject it into the mold cavity through the injection mechanism.

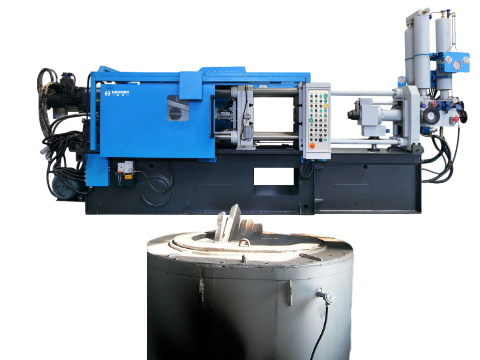

Depending on the different metal material and die-casting technology, the application of chamber mainly include: hot chamber machine and cold chamber machine.

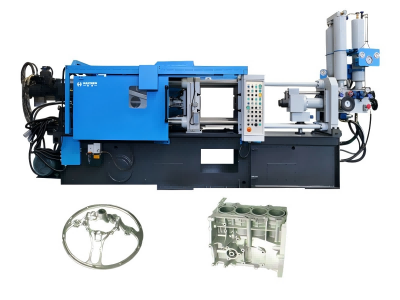

Cold chamber die-casting machine

The pressure chamber and the melting furnace of the cold machine are separated. The molten metal needs to be scooped from the heat-insulating furnace and poured into the pressure chamber before die casting. Cold chamber die-casting machines are usually used to process materials with high melting points such as aluminum

This method application of sleeve for die-casting machine is used to create parts from metals with higher melting points, such as aluminum and copper.

It’s often used to make automotive components like engine blocks and gear housings, as well as electronic components and electric housings.

Application of chamber for die casting machine

- Improve casting quality

- Vacuum die casting technology

- Adapt to different alloy materials

- Improve production efficiency

- Special process applications

Improve casting quality

The design of the cold chamber machine improves the problems of pores, shrinkage holes, shrinkage and so on inside the casting, and improves the density and quality of the produtcs.

Vacuum die casting technology

In some advanced die-casting machines, the pressure chamber can be integrated with a vacuum system to optimize the die-casting process.

This reduce the scrap rate, and improve the effect of low-speed die casting.

Adapt to different alloy materials

The die-casting machine’s pressure chamber design enables it to be suitable for metal materials with different melting points

Such as low-melting-point non-ferrous alloys such as zinc and lead.

As well as high-melting-point alloys such as aluminum alloys and magnesium alloys.

Improve production efficiency

The large-tonnage horizontal cold chamber casting machine can achieve efficient production of medium and large die-casting parts.

And the clamping force and injection force have been significantly improved.

Special process applications

For example, in solid die casting and semi-solid die casting technology, the die chamber needs to have a special structure and working principle to adapt to the addition and processing of different forms of metals

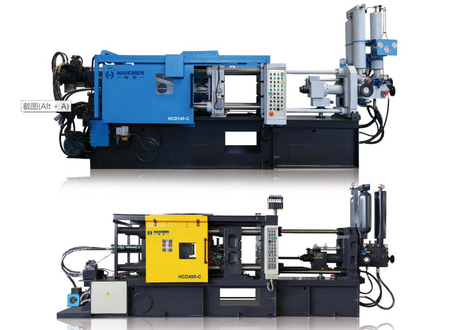

Haichen die casting machine

Haichen machinery produces high pressure die casting machines.

Because it includes both cold chamber die casting machines and hot chamber die casting machines.

They are characterized by high durability and precision.

Haichen Medal Manufacturing Machine’s Outstanding Advantages

- Precision Mould Design and Manufacturing

- Real-time Process Monitoring System

- High-speed Injection Moulding

- Quick Die Change System

Precision Mould Design and Manufacturing

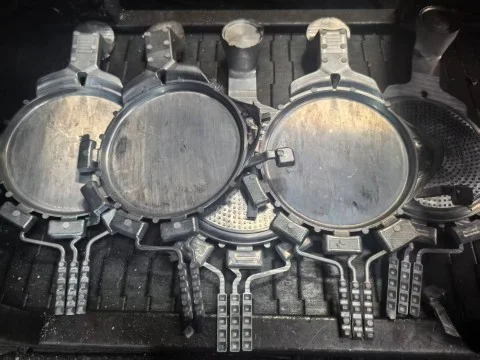

The mould is one of the most critical components in the die-casting process.

Therefore, mould manufacturing requires precision machining and process control to ensure the accuracy of medal shape and dimensions.

Haichen employs advanced CNC engraving machines to carve precision moulds layer by layer.

We guarantee every detail meets design specifications.

Real-Time Process Monitoring System

Haichen die-casting machines incorporate real-time process monitoring systems that continuously track parameters such as temperature and pressure.

This ensures each casting adheres to stringent quality standards.

The system guarantees medal casting quality by precisely programming injection speed and pressure curves, promptly correcting deviations during moulding.

High-Speed Injection Moulding

High-speed die-casting machines employ high-pressure injection technology to inject molten metal into moulds at extreme velocity.

This high-speed injection not only shortens production cycles.

It also enables greater part output within reduced timeframes, significantly enhancing production efficiency.

Quick Die Change System

The Quick Die Change System (QDC), widely adopted in aluminium die casting, not only reduces die changeover time.

It also minimises production downtime and equipment idle periods caused by die changes.

This enables the production of more batches within the same timeframe, thereby enhancing equipment availability and overall productivity.