Crankcase die casting machines are widely used in the automotive and industrial engine manufacturing sectors, with applications that span from production to quality control and process optimization.

Application of Crankcase die casting machine

Crankcase (Crankcase) die-casting machine applications are mainly focused on the following areas.

Automotive industry

- The crankcase is a key component of an internal combustion engine and is used to house the main moving parts of the engine, such as the crankshaft, connecting rods and pistons.

- Crankcases are typically manufactured using a high-pressure die casting process to ensure their high strength and durability.

- The crankcase die casting process involves using high pressure to inject molten metal into a mold cavity to produce a part with high dimensional accuracy.

- This process produces lightweight, high performance crankcases that meet the lightweight and performance requirements of modern automobiles.

Motorcycles and small engines

- In the field of motorcycles and small engines, die-casting technology for crankcases is also widely used. For example, motorcycle crankcases are often manufactured using high-pressure die casting processes to achieve lightweight and high performance.

- These crankcases not only need to meet the strength requirements, but also need to have good corrosion resistance and dimensional stability.

Industrial Machinery

- The industrial machinery industry also makes extensive use of die casting machines to produce critical components such as crankcases.

- These components require high strength, durability and precision.

- The die casting process allows for the production of crankcases with complex geometries and thin-walled designs to meet the high performance and reliability requirements of industrial machinery.

Electronics and home appliance industry

- Although crankcases are mainly used in the mechanical field, die casting technology also has applications in the electronics and home appliance industries.

- For example, die casting can be used to produce housings for some small electronic devices or components for home appliances.

Crankcase die-casting machine has a wide range of applications. It covers a variety of fields such as automobiles, motorcycles, industrial machinery, electronics, home appliances and aerospace. Its main advantage lies in its ability to produce high-strength, high-precision and lightweight parts.

Advantages of Die Casting for Crankcases

High Precision: Die casting ensures accurate dimensions and smooth surfaces, reducing the need for additional machining.

Mass Production: The process is highly efficient and suitable for large-scale production.

Strength and Durability: The high-pressure injection results in a dense, strong structure capable of withstanding the stresses of engine operation.

Lightweight Components: Aluminum and magnesium alloys contribute to fuel efficiency and reduced emissions.

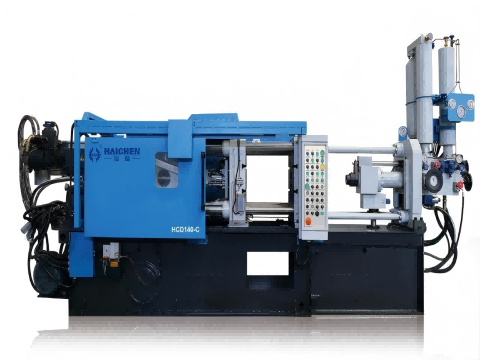

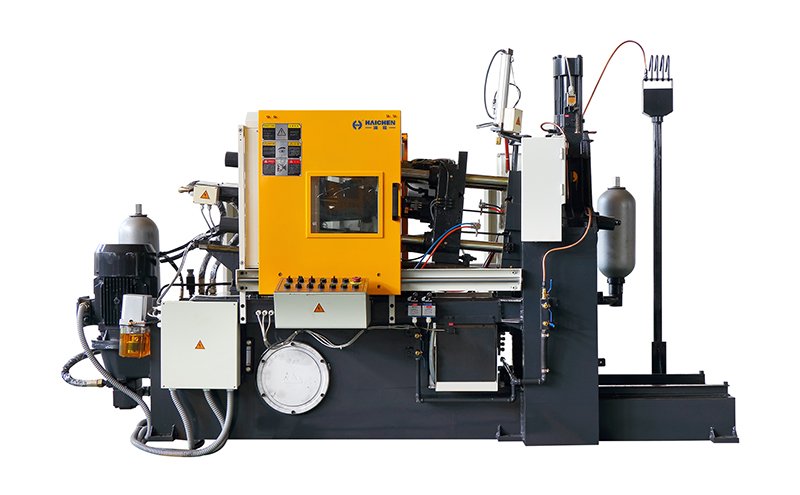

Haichen Crankcase die casting machine supplier

Ningbo Haichen Machinery is a professional die casting machine manufacturer. We specialize in the production of cold chamber and hot chamber die casting machines, as well as related auxiliary equipment.

Haichen crankcase die casting machine features

Cold chamber die casting machine: Haichen provides cold chamber die casting machines suitable for crankcase production. These machines are suitable for aluminum alloy, magnesium alloy and other materials.

Customized solutions: According to customers’ needs, Haichen can provide customized die casting machines and molds to meet the production of crankcases of different sizes and materials.

Technical support and innovation: Haichen adopts advanced computer-aided design (CAD/CAE) and finite element analysis technology to ensure the high performance and reliability of the machines.

Auxiliary Equipment Package: Haichen also provides complete auxiliary equipment, such as conveyors, vacuum equipment, mold temperature controllers, industrial robots, etc. It can improve production efficiency and product quality.