Die casting machine ladle application is the transfer of molten metal from the furnace to the injection chamber or mold.

In cold chamber die casting, the ladle is an indispensable tool for pouring molten metal from the furnace into the injection chamber and then injecting it into the mold by means of a hydraulic piston.

The design and material selection of the ladle is critical to ensure a stable transfer of molten metal and to prevent temperature loss.

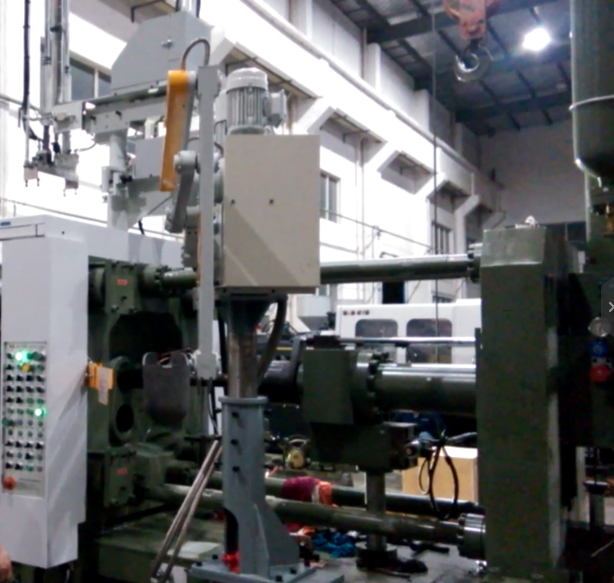

Die casting machine ladle application

Metal transfer of die casting machine ladle application

- The ladle scoop molten metal from the furnace and pour it into the shot sleeve of the die casting machine.

- And this process ensures an exact amount of molten metal is delivered, which is crucial for maintaining product quality and consistency.

Automation in Large-Scale Production

- In modern die casting machines, automatic ladling systems can improve efficiency and reduce human intervention.

- Automated ladles can ensure precise timing, quantity, and pouring angle, minimizing metal waste and improving repeatability.

Prevention of Metal Contamination

- The design of ladle is to handle molten metal without introducing impurities or causing significant temperature loss.

- Proper ladling prevents contamination of the molten metal, ensuring the mechanical properties of the final casting.

Temperature Maintenance of die casting machine ladle application

- Some ladles are designed with insulation or heating systems to maintain the temperature of the molten metal during transfer.

- This reduces defects caused by temperature inconsistencies, such as incomplete filling or cold shuts.

Reduction of Spillage

- A well-designed ladle minimizes spillage and exposure of molten metal to air, and reducing oxidation and defects in the cast product.

Types of Ladles in Die Casting

- Manual Ladles: Used in small-scale operations for manual transfer of metal.

- Automatic Ladles: Integrated with robotic systems in high-volume die casting machines.

- Tilting Ladles: Equipped with mechanisms for controlled tilting to pour molten metal accurately.

Considerations for Ladle Design and Use:

- Capacity: Must match the metal volume requirements of the die casting shot.

- Material: Made from heat-resistant materials, such as ceramic or high-grade steel, to withstand high temperatures.

- Accuracy: Should provide precise control to avoid overpouring or underpouring.

- Safety: Proper design ensures operator safety by minimizing splashes and excessive handling of molten metal.

Haichen die casting machine ladle

Haichen is known for providing various solutions in die casting operations, including ladles and other auxiliary machinery.

If you need specific technical details about Haichen ladles, such as dimensions, material specifications, or compatibility with particular die casting machines. Welcome to consult us.

Die casting machine ladle is mainly to safely and efficiently transport molten metal from the furnace to the injection chamber, and to ensure the stability of the entire casting process and product quality.