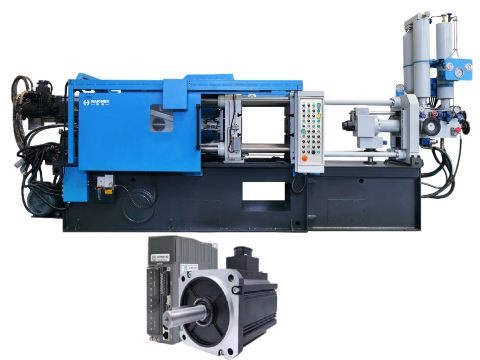

Servo motor die casting machine application in energy saving and precise control, simplified structure and extended life and other aspects.

Servo Motor is a special electric motor. That is mainly used to accurately control the position, speed and acceleration of mechanical motion. It achieves precise regulation of output through a closed-loop control system. And it is widely used in robots, industrial automation, RC vehicles and other applications that require precise control.

The servo motor is a precision actuator that integrates a motor, a gear set, a feedback sensor, and a control circuit. It achieves precise control of mechanical motion through a closed-loop control system. Its high precision, fast response, and stability make it an indispensable key component in modern automation and robotics.

What is the die casting machine servo motor?

The die-casting machine servo motor is a core component of the servo drive system used in the die-casting machine. Its main function is to drive the hydraulic actuator by accurately controlling the motor’s speed and torque. This servo motor is usually used in conjunction with an oil pump, pressure sensor, flow sensor, and electronic control system. It improves the control accuracy, energy saving effect, and production efficiency of the die-casting machine.

Following are detailed description:

Energy saving and precise control

Servo motors achieve high-precision motion control through closed-loop control systems. It can significantly improve the energy efficiency and production efficiency of die-casting machines.

For example, the servo energy-saving hydraulic control system drives the oil pump through the servo motor to achieve precise control of the hydraulic system. Thereby reducing energy consumption and extending the life of the equipment.

The application of servo motors in die casting machines has significant advantages, especially in energy saving and precise control.

- Energy saving effect

- Precise control

- Improve production efficiency

Energy saving effect of servo motor die casting machine application

Servo motors significantly reduce energy consumption by optimizing energy use. For example, servo energy-saving hydraulic control systems can save up to 60% of energy while improving production efficiency and precision.

In addition, servo drive systems further reduce energy consumption through dual closed-loop control (pressure and flow), with energy savings of up to 45%-75%.

In actual cases, die-casting machines using servo motors have reduced energy consumption by 20%-30% compared to traditional hydraulic systems.

Precise control of servo motor die casting machine application

Servo motors’ high response speed and precise control capabilities enable them to perform well in the die-casting process.

For example, servo motors can achieve fast start and stop and high-precision speed and pressure control. Thereby reducing porosity defects and improving product quality.

The real-time feedback and learning control functions of servo motors further ensure the stability and consistency of the injection process.

Improve production efficiency

Servo motors improve the operating efficiency of die-casting machines by reducing the lag and energy loss of the hydraulic system.

For example, servo drive systems can shorten cycle times and improve production efficiency.

In addition, the efficient control algorithm and fast response capabilities of servo motors enable die-casting machines to complete complex injection processes in a shorter time.

Dynamic adjustment and flexibility

- Dynamic adjustment capability

- Flexibility and adaptability

- High precision and high efficiency

Servo motors can quickly respond to changes in production needs and achieve online adjustment of mold. Clamping force to avoid problems caused by insufficient clamping force.

This adjustment accuracy is higher than that of hydraulic motors, and can achieve precise positioning and reduce energy waste.

Dynamic adjustment capability

The servo motor can achieve real-time adjustment of the operating parameters of the die-casting machine through its high-precision control capability.

For example, the servo-driven die-casting machine can optimize the control of the mold closing force by adjusting the pressure and flow sensor signals of the hydraulic actuator, thereby improving production efficiency and product quality.

In addition, the servo motor can also achieve dynamic adjustment of the punch buffer system through the pre-acceleration function, thereby reducing mold deformation and improving forming accuracy.

Flexibility and adaptability

The die-casting machine driven by the servo motor has higher flexibility and can adapt to different types of die-casting process requirements.

For example, the servo motor can quickly adapt to different load and position requirements on the production line by changing the speed and force control mode.

This flexibility makes the servo motor-driven die-casting machine particularly suitable for scenarios where frequent mold changes or production process adjustments are required.

High precision and high efficiency

The servo motor drive system can achieve higher control accuracy and response speed through closed-loop control technology.

For example, the weak magnetic overspeed performance and vibration resistance of the servo motor enable it to maintain high efficiency and stability at high speed operation.

In addition, the high rigidity and torsional rigidity of the servo motor further improve the positioning accuracy and operational stability.

Simplified structure and extended life

Die-casting machines using servo motors usually have simpler structural designs. And due to the improvement of key components, the service life of the equipment is extended.

For example, the servo-driven die-casting machine simplifies the mechanical structure and improves the control accuracy by using the servo motor and oil pump together.

Integrated Design of servo motor die casting machine application

Servo motors integrate the motor, gear train, feedback sensor, and control circuitry into a single unit, directly driving the oil pump. This replaces the complex network of valves and piping in traditional hydraulic systems, significantly reducing the number of mechanical components. For example:

- The servo motor and oil pump work together to simplify hydraulic circuit design.

- Direct-drive servo motors (e.g., frameless designs) can be embedded directly into the equipment, eliminating transmission components.

Optimized Closed-Loop Control Systems

- Dual closed-loop control is achieved through pressure/flow sensors and electronic controllers:

- Real-time adjustment of oil pump output eliminates the need for traditional proportional valves or relief valves.

- Reduces redundant hydraulic components (such as accumulators), resulting in a more compact overall system.

Servo motor driven die casting machines achieve higher production efficiency and longer equipment life by optimizing the accuracy and response speed of the control system.

For example, the servo system can respond quickly (<50ms), which shortens the production cycle by 5% to 7% compared with ordinary machines, while reducing vibration and shock, thereby extending the service life of the machine. In addition, the weak magnetic overspeed performance and vibration resistance of the servo motor further improve the reliability and durability of the equipment.

Reduced Mechanical Wear

- Low-Vibration Operation: The servo motor has a short response time (<50ms) and smooth motion, reducing shock and vibration, and minimizing fatigue damage to key components (such as molds and hydraulic cylinders).

- Precise Control: The closed-loop system avoids pressure overshoot and flow fluctuations, reducing wear on seals and piping.

Thermal Management and Energy Optimization

- Energy Saving and Cooling: The servo system delivers power on demand, reducing inefficient energy consumption and lowering hydraulic oil temperature rise by 30%, extending seal and hydraulic oil life.

- Oil-Cooled Motor Design: Some servo motors utilize oil cooling to improve heat dissipation efficiency and prevent motor overheating and damage.

Reinforced Key Components

- Motor Durability: The servo motor utilizes H-class insulation material, a fully encapsulated stator structure, and a preloaded bearing design, offering strong vibration resistance and ensuring long-term stable operation.

- Hydraulic System Protection: Reduced oil temperature reduces oxidation, and combined with optimized circuit design (such as zero-drag cylinders), extends pump and valve life.

Hybrid drive system of Servo motor die casting machine application

In some die casting machines, servo motors are used in combination with hydraulic systems to form a hybrid drive system.

This system can control the servo motor and hydraulic system separately during the injection phase and the pressurization phase to optimize the production process.

Combination of Hydraulics and Servo Motors

A hybrid drive system integrates servo motors and hydraulic systems. During the die-casting process, different stages (such as low-speed injection, high-speed injection, and pressurization) are independently controlled by the servo motor and hydraulic system to achieve optimal performance.For example:

- Servo motors: Responsible for precise control of position, speed, and force, especially in stages requiring high responsiveness and energy savings (such as flow control during the initial injection phase).

Hydraulic systems: Leverage their power density advantages during high-pressure or high-dynamic demand stages (such as pressurization). - Closed-loop control: The system uses real-time feedback from pressure/flow sensors, and an electronic controller (such as a PID algorithm) dynamically adjusts the servo motor’s speed and torque to achieve precise matching of pressure and flow.

Significant Energy Savings

Conventional hydraulic systems consume high energy due to overflow from the fixed displacement pump. Hybrid drives, however, use servo motors to deliver energy on demand, reducing overflow losses. Evidence suggests energy savings of 40%-80% (conventional systems reduce energy consumption by 20%-75%).

- High Precision and Fast Response:

The servo motor’s response time is as short as 30ms (compared to hundreds of milliseconds for conventional systems), and pressure fluctuations are controlled within ±0.05MPa, ensuring product dimensional consistency. - Improved Production Efficiency:

The fast response reduces production cycle time by 5%-12%. Combined with online parameter adjustment (such as clamping force), it adapts to high-mix production.

Significant energy-saving effect

The application of servo motors has greatly reduced the energy consumption of die-casting machines.

For example, the oil pump drive device is controlled by a servo motor and can automatically adjust the pump station pressure according to different parameter requirements, which has a significant energy-saving effect.

Intelligence and automation

Servo motors, combined with human-machine interfaces (HMI) and programmable controllers, can achieve complex parameter settings and automated control, improving operational convenience and production efficiency.

Therefore, the application of servo motors in die-casting machines not only improves the energy efficiency and production efficiency of the equipment, but also simplifies the structural design, extends the life of the equipment, and enhances the flexibility and intelligence level of the system.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We have both servo motor and standard motor die casting machines for option. When you need any professional recommendations, feel free to contact us. We will help select the most suitable type machine for your production.