Die casting plunger ring application includes improve production efficiency and product quality, reduce defects, etc.

The plunger ring used in the die casting process is an important part of the die casting mold. Its main function is to ensure the accuracy and efficiency of the die casting process. The plunger ring usually installes on the plunger rod. It to seal and guide the movement of the plunger rod in the mold cavity. Thereby preventing the leakage of molten metal and ensuring the complete filling of the mold cavity.

The application of plunger rings in the die casting process covers many aspects, from improving production efficiency, reducing defects, extending equipment life to adapting to different materials and process requirements. By optimizing the design and process parameters of the plunger ring, that can improve the die casting quality and production efficiency.

- Improve production efficiency

- Reduce Maintenance and Replacement Frequency

- Improve product quality

- Reduce defects and improve surface quality

- Extend Equipment Life

- Adapt to different materials and process requirements

- Innovative design and technological improvement

Improve production efficiency

- Reduced Downtime

- Energy and Cost Savings

- Increase Injection Speed

Plunger rings play a key role in the die casting process. Especially in the die casting of metals such as aluminum, zinc, and magnesium. By optimizing the design and material selection of plunger rings, production efficiency and casting quality can be significantly improved.

Reduced Downtime

High-strength forged materials (such as ASL42 stainless steel) are more wear-resistant than traditional cast iron rings, significantly reducing failure rates and increasing machine uptime by 30%-40%.

Energy and Cost Savings

Energy-efficient punch rings reduce hydraulic system energy consumption, reducing long-term operating costs by approximately 10%.

Increase Injection Speed

Four-stage injection control enables fast strokes while maintaining smooth metal flow, reducing cycle time by 5%-8%.

Reduce Maintenance and Replacement Frequency

- Material and Structural Optimization

- Lubricant Selection

- Maintenance Intervals and Key Points

- Practical Benefits

Nano-coating and alloy materials enhance corrosion resistance, extending the punch ring replacement interval from six months to over a year.

Material and Structural Optimization

- Using highly heat-resistant and wear-resistant copper alloy or nitrided H13 rings significantly extends piston ring life. While copper rings cost more than standard nitrided rings, they only take one minute to replace, while replacing the entire sleeve takes 2-3 hours, resulting in lower overall costs.

- The incorporation of a sacrificial sealing ring in the design concentrates most wear on the ring, eliminating the need for frequent replacement of the entire piston.

Lubricant Selection

- Using a dedicated high-performance lubricant can reduce piston tip usage by approximately 50% and increase projectile sleeve life by 20%.

- This lubricant also keeps the work area clean, reduces oil leakage, and reduces the risk of slips for operators.

Maintenance Intervals and Key Points

- Center lubrication maintenance is recommended after 500-700 firing cycles to prevent corrosion and wear of the rings due to high-temperature metal.

- Regularly inspect the ring surface condition and promptly replace rings showing visible wear or cracks to avoid metal leakage and reduced machine accuracy caused by ring failure.

Practical Benefits

- Reduced Replacement Frequency: Through improvements in both material and lubrication, the piston ring replacement cycle has been reduced from 60 rings per month to approximately 30, halving the number of replacements.

- Reduced Downtime: The rapid ring replacement (1 minute) compared to sleeve replacement significantly reduces overall downtime and improves production efficiency.

- Cost Savings: In addition to direct part costs, the reduced downtime and sleeve heating time (3-4 slow-fire shots) also significantly reduce indirect costs.

HAICHEN Solutions for die casting plunger ring

We used help our clients optimize die casting plunger ring this small part for big results.

- Solve Leakage in a High-Volume Zinc Operation

- HAICHEN’s Advantage in System Compatibility

Solve Leakage in a High-Volume Zinc Operation

For example, one Haichen customer who making zinc alloy fittings had severe leakage every two days, requiring frequent ring changes and cleanup. HAICHEN engineers found they were using a standard ring not suited for their fast cycle time and high temperature. We recommended a premium-grade, heat-treated ring with a special angle cut. This new ring lasted over two weeks under the same conditions. Leakage stopped, scrap rate dropped, and productivity increased due to less downtime.

HAICHEN’s Advantage in System Compatibility

This case shows our strength. As a machine manufacturer, we understand how every part, down to the plunger ring, affects the whole system.

- We provide genuine, application-tested rings that match our machines perfectly. This ensures optimal performance, long life, and consistent quality for our clients. Our technical support helps you select the right consumables, maximizing your investment.

- The plunger ring is a small but vital component. Its proper application ensures leak-free operation, consistent part quality, and protection for expensive machine parts.

- Selecting the correct material and size, and following a proactive replacement plan, are essential. As demonstrated by HAICHEN, the right technical choice for this component solves major production headaches. Partnering with a machine builder who offers integrated consumable solutions guarantees better performance and lower total operating cost for your die casting business.

Improve product quality

- Reduced Defect Rate

- Improved Casting Density and Strength

- Improved Surface Quality

- Achievable Complex Structures

Reduced Defect Rate

- Improved Casting Density and Strength

- Improved Surface Quality

- Achievable Complex Structures

An aluminum alloy die-casting plant saw an approximately 30% reduction in overall defects (porosity, shrinkage, and surface scratches) after using customized copper alloy punch rings.

Improved Casting Density and Strength

A stable acceleration curve ensures complete metal filling within the die cavity, increasing casting density by 2%-3% and correspondingly improving mechanical properties.

Improved Surface Quality

Optimized sealing and guiding minimize metal leakage and punch impact, significantly reducing surface scratches and indentations on the casting.

Achievable Complex Structures

Extended or specially shaped punch rings enable precise delivery into deep holes and fine-walled structures, reducing the need for post-processing and increasing overall product yield by approximately 15%.

Reduce defects and improve surface quality

- Select high-performance materials

- Precisely match the barrel

- Optimize the velocity profile

- Integrate vacuum technology

- Regular inspection and replacement

The design of the plunger ring directly affects the fluidity and filling effect of the molten metal.

- By optimizing the geometry of the plunger tip and the use of lubricants, pores and other defects in the casting can be reduced.

- Thereby improving the surface quality and mechanical properties.

- In addition, the application of vacuum-assisted die casting technology has also shown that by controlling the plunger pressure and speed. Defects can be further reduced. And the density and strength of the casting can be improved.

Select high-performance materials

Nitrided steel or nano-coated alloys are preferred for their balance of wear resistance, high temperature resistance, and thermal conductivity.

Precisely match the barrel

Ensure the inner diameter of the ring fits within a tolerance of ±0.02mm with the barrel wall to avoid gaps that could cause leaks.

Optimize the velocity profile

Use a step-by-step velocity control system, especially maintaining appropriate stroke after the V-P turning point to reduce filling pressure.

Integrate vacuum technology

Use vacuum suction before and after high-pressure injection to further suppress pore formation.

Regular inspection and replacement

Establish a wear monitoring system for the rings, and replace them when wear reaches 0.1mm to prevent seal failure.

Extend Equipment Life

The design of the plunger ring not only affects the quality of the casting, but also has an important impact on the life of the equipment.

For example, using high-quality plunger tip materials (such as beryllium copper alloy) can improve the durability of the plunger tip. Thereby extending the service life of the equipment.

In addition, the plunger sleeve, as a protective layer of the plunger, can absorb impact and reduce wear, further extending the overall life of the plunger.

Adapt to different materials and process requirements

- Optimize process parameters

Different types of plunger tips are suitable for different materials and process requirements. For example, Cooled Plunger Tips are suitable for materials that require rapid cooling. While ordinary plunger tips are suitable for general die casting applications.

In addition, plunger tip designs for specific materials (such as aluminum, zinc, and magnesium) can further optimize filling effects and casting performance.

Optimize process parameters

Plunger pressure and speed are important parameters that affect the die casting process. Studies have shown that appropriate plunger pressure and speed can effectively control the fluidity and filling effect of molten metal, thereby improving the quality and consistency of castings.

For example, in high-pressure die casting, by adjusting the plunger pressure and speed, it can reduce the proportion of pores in the casting. And improve its mechanical properties.

Innovative design and technological improvement

As technology develops, the design of plunger rings is also constantly innovating. For example, a new type of in-line plunger process device thickens the metal by injecting the piston into the mold, thereby reducing the processing time and cost of the casting.

In addition, the self-alignment design of the plunger tip and the application of cooling tubes also further improve the accuracy and efficiency of the die casting process.

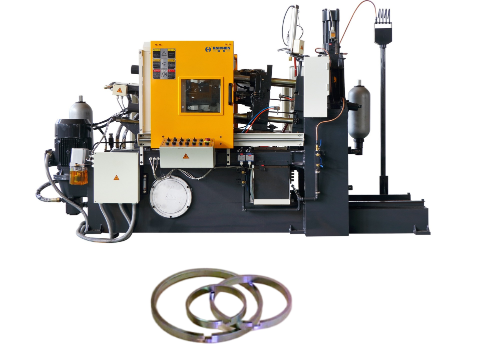

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.