Quick Die Change Systems enables the automation of the mold-changing process, significantly enhancing the production speed, efficiency and productivity of the workshop.

A quick die change system is an automated or semi-automated system.

Designed to reduce the time required for die casting machines to change molds, improving production efficiency, safety, and flexibility.

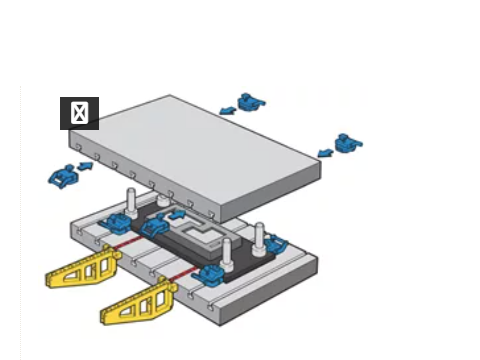

These systems typically include die clamping devices, die lifters, power units, and other ancillary equipment for quick and accurate mold changes.

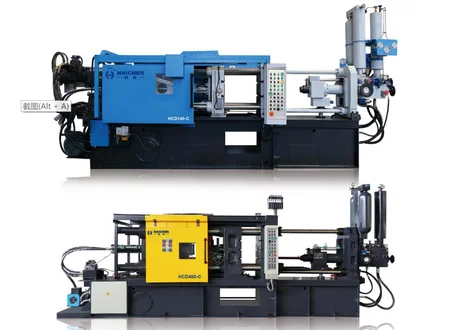

Haichen’s quick die change system is an automatic die changing system that can be specifically designed for hydraulic and mechanical power presses and press production lines.

This system automates the die changing process and provides increased speed, efficiency and productivity to a workshop.

The Quick Die Change System not only reduces die change time, but also promotes diverse small batch production runs and streamlines production management.

Why is a Quick Die Change Systems necessary?

Quick mold changeover is a specialty of Haichen, which can reduce the mold replacement time from several hours to just a few minutes.

Introducing the Quick Mold Changeover (QDC) program is usually the result of transitioning to a lean production method.

The most well-known lean production method is the Just-In-Time production system. The quick mold changeover solution can lower your manufacturing costs.

The quick mold changeover process is simple and easy to implement, and is applicable to all mold or tooling replacements.

It is language-independent, and any manufacturer can utilize this technology to improve product quality and production efficiency.

If you want to learn more about our information on the quick mold changeover solution for press machines, you can contact us at any time.

Distinguish between internal and external operations

- Externalization of internal operations

- Eliminate adjustments and waste

Internal operations need to be stopped to complete.While external jobs can be prepared while the equipment is running.

Externalization of internal operations

Standardized tooling and pre-positioning of mold parameters allow converting the externalization of operations that would otherwise require shutdown operations into external preparations.

Eliminate adjustments and waste

Reduce commissioning time through tool standardization, automated clamping devices (e.g. hydraulic clamps) and parallel operation.

Typical system components include a mold transfer arm, a clamp, a mold lifter, a gas-hydraulic power unit and a control system.

Which can be quickly clamped and released by hydraulic or pneumatic technology.

The relationship between the die casting process and the need for mold change

- Die casting process

- High-frequency mold change requirements

- Large-scale mold challenges

- Costly downtime

Die casting process

The die casting process mainly includes the stages of melting, injection, cooling, demolding and dressing.

Molds are the core components of the die casting process, and their replacement directly affects production efficiency and product quality.

For example, the mold replacement of large die castings is frequent and complex, and the weight of the mold, structural complexity.

And the connection of temperature control systems such as oil cooling and water cooling circuits need to be considered, resulting in long replacement times and high costs.

Secondly, the mold replacement time is long, and the environment such as high temperature and oil pollution increases the difficulty of operation and safety risks.

In addition, frequent mold changes affect the flexibility of the production line, especially in multi-model production, where it is difficult for a single mold to adapt to the needs of multiple varieties.

High-frequency mold change requirements

Multi-variety, low-volume orders (such as auto parts) need to change molds frequently.

The industry’s products are frequently updated, resulting in molds that need to be updated frequently to adapt to new designs.

For example, the frequency of car facelifts is high, and the molds need to be rematched.

The demand for customer customization has increased, and the production line needs to change molds frequently to adapt to different products, resulting in frequent replacements.

For example, low-volume and diverse production models require rapid mold change technology to reduce downtime.

Large-scale mold challenges

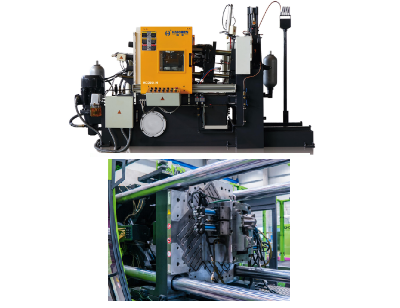

Integrated die casting technology makes molds weigh hundreds of tons, and traditional mold changes are time-consuming and dangerous.

The size and weight of large molds are huge, and special equipment and multiple debugging are required during processing, making it difficult to ensure the processing accuracy.

Secondly, the processing equipment of large molds is expensive, and it requires multiple equipment to cooperate, and the processing cycle is long.

Costly downtime

Downtime per hour can cost tens of thousands of dollars, especially in the production of high-precision automotive structural parts.

Downtime can reduce productivity by 5% to 20%, and businesses can lose millions of dollars annually due to downtime. Indirect costs include labor costs, equipment maintenance expenses, product quality issues, and reduced customer satisfaction.

Downtime can be reduced by using quick mold change technology (SMED), modular design, and automated equipment.

Specific application scenarios of SMED in die-casting

- Large-scale mold change

- Multi-channel energy connection

- Multi-variety low-volume production

- AGV and robot integration

- Cloud management

- Time efficiency

- Extreme case

- Economic benefits

- Quality & Safety

Large-scale mold change

Haichen is located in Ningbo, China, and after years of development, now customers are all over the country and abroad.

Haichen offers the most comprehensive range of magnetic solutions, including workpiece fixation, die clamping and material handling.

And a quick mold change system to support the production of larger-size structural parts, and the mold change efficiency is increased by 80%.

Multi-channel energy connection

Through multi-port energy routers, multi-energy complementary systems.

And intelligent communication technologies, we can achieve efficient, flexible, and sustainable use of energy.

Its core advantages are to improve energy utilization efficiency, reduce losses

And enhance system reliability and adaptability, which is an important development direction for future energy systems.

Multi-variety low-volume production

A die-casting workshop shortened the 280-ton mold change time from 143 minutes to less than 30 minutes through SMED, realizing fast delivery of small orders.

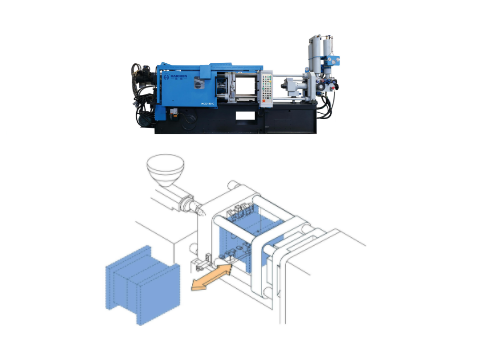

AGV and robot integration

Fuwei Machinery’s intelligent mold change system combined with AGV handling (maximum load of 500 tons) realizes automatic mold storage and transportation.

Cloud management

LK-NET cloud die-casting system monitors the mold change process in real time and optimizes parameter adjustment.

Data on the impact of SMED on die casting production efficiency

Time efficiency

Mold change time can be reduced by 70%-90%, for example, company B reduced the mold change time from 59.46 minutes to 32.39 minutes through a standardized process.

Extreme case

One study reduced mold change time from 49 minutes to 552 seconds with SMED, reducing downtime by 81.2%.

Economic benefits

Enterprises increase production efficiency by about 30%, and the annual cost savings can reach hundreds of millions of yuan (for example, an enterprise saves IDR 360 million per year.

Inventory turnover rate increases: reduce work-in-process backlog and reduce capital occupation.

Quality & Safety

The first article pass rate is improved, and the error rate in the adjustment process is reduced.

The automatic clamping device reduces the risk of manual operation and reduces the accident rate.

Specific application scenarios of QDC in aluminum alloy die-casting

- Auto parts production

- Consumer Electronics Enclosure Manufacturing

- Medium-sized enterprise

Auto parts production

After the introduction of QDC in an automobile die-casting factory.

The number of daily mold changes increased from 4 to more than 6 times, and the production efficiency increased by 30%.

For example, the production of engine blocks realizes the rapid switching of different types of molds through standardized mold interfaces.

And at the same time ensures that the dimensional accuracy is stable at level 4 (the traditional process is level 6-7).

Consumer Electronics Enclosure Manufacturing

In response to the diverse needs of mobile phone/tablet enclosures, QDC compresses the time for mold replacement and debugging from weeks to hours.

The mold shifting trolley and roller guide work together to improve the transportation and positioning efficiency of the 15-ton mold by 60%.

Medium-sized enterprise

Under the trend of order fragmentation, a medium-sized enterprise uses QDC to process 8 different molds in a single day, increase the inventory turnover rate by 40%, and reduce sluggish materials by 25%.

Haichen‘s Quick Mold Change System

Haichen’s quick mold change system is suitable for injection molding machines from 50 to 400 tons to achieve fast mold change times and thus reduce machine downtime.

The system provides uniform die clamping force that acts on the entire contact surface without any changes to the mold.

Which allows for high-quality parts even when the mold is used for the first time, dramatically reducing tooling change time (up to 90%) compared to conventional procedures.

And with its simple operation, one operator can easily and safely operate it without having to work inside the machine.