Zinc alloy die casting applications cover a wide range of automotive, electronics, construction, medical, household goods, toys and gifts.

Application of zinc alloy die casting in daily life

This production technology is a mature industry with several wide applications.

Let’s list the different applications of zinc alloy die casting and its characteristics of the detailed analysis:

- Automotive industry

- Electronic communication industry

- Construction industry

- Household goods

- Toy and gift industry

- Medical devices

- Other industries

Automotive industry

Zinc alloy in the automotive industry occupies an important position.

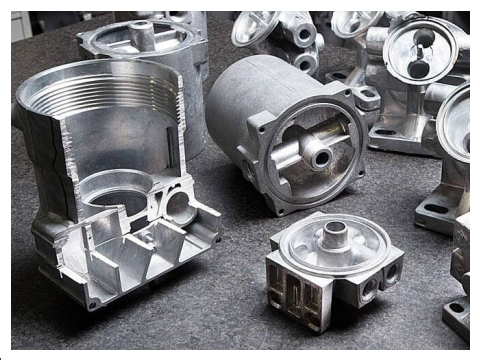

Mainly used in the production of internal engine parts (such as cylinder head, cylinder block, piston, etc.).

Key parts of the transmission system (such as gears, bushings, bearing housings, etc.).

Body structure parts (such as door handles, window lifters, etc.) and automotive electronic system components.

Zinc alloy die casting is widely used because of its high strength, wear resistance and precise size control.

Electronic communication industry

Zinc alloy die casting in the electronic communication industry for the manufacture of lightweight and durable precision parts.

Such as mobile phones, tablet PCs, laptop shells, as well as connectors and switches.

The high ductility and low melting point of zinc alloy enable it to produce complex shapes and thin-walled structures.

It also offers good dimensional stability and surface quality.

Construction industry

Zinc alloy die casting in the construction industry is mainly used for hardware accessories (such as door and window hardware), lighting fixtures and decorative parts.

The high strength and durability of zinc alloy make it an ideal material for architectural hardware.

Household goods

Zinc alloy die casting is widely used in household goods manufacturing.

Including bathroom hardware (such as shower heads, faucets), furniture accessories (such as pulls, hinges) and decorative lines.

The smooth surface and corrosion resistance of zinc alloy make it suitable for use in these products that require aesthetics and practicality.

Toy and gift industry

Zinc alloy die casting is used in the toy and gift industry to make toys (e.g. toy cars, robots, gun models.

as well as gifts and souvenirs (e.g., badges, medals, keychains, etc.).

The lightweight and malleable nature of zinc alloys allows for the production of intricately detailed products.

Medical devices

Zinc alloy die casting is used in the medical device industry for the production of surgical instruments, medical devices and prosthetics.

The high strength and corrosion resistance of zinc alloys make them ideal for medical devices.

Other industries

Consumer electronics: such as computer housings, connectors and switches.

Security equipment: such as locks and smart lock housings.

New Energy Vehicles: Used to manufacture lightweight parts to enhance vehicle performance.

Small home appliances: such as kitchen appliances and power tools.

With its excellent physical and mechanical properties, casting performance and surface treatment ability, zinc alloy die casting in a number of industries to show a wide range of application potential.

From automotive to electronic communication, from household goods to medical devices, Haichen’s zinc alloy die casting technology provides efficient, economical and reliable solutions for modern industry.

How is zinc used in die casting?

Zinc alloy because of its low melting point, high fluidity, excellent mechanical properties and the advantages of surface treatment ability, can easily through the die casting process to produce products

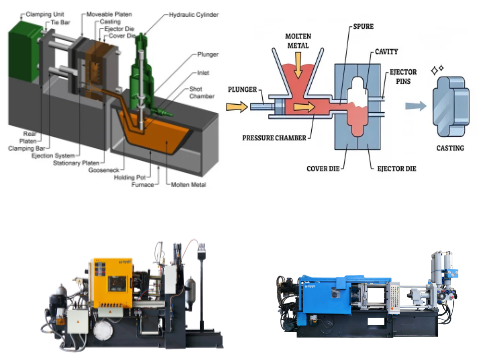

Zinc alloy die casting process mainly includes the following steps:

- Mould preparation

- Zinc alloy melting

- Injection moulding

- Cooling and Ejection

- Trimming

Mould preparation

Design and manufacture precision zinc alloy die casting mould, mould usually consists of two parts: moving mould and fixed mould. The mould needs to have high precision and durability to ensure the quality of parts.

Zinc alloy melting

The zinc alloy material is heated to about 380℃ to make it completely melt into liquid state. Melting is usually carried out by the molten alloy method or pressure casting method.

Injection moulding

The molten zinc alloy is injected into a pre-set mould cavity under high pressure. Injection speeds of up to 100 metres per second and extremely short filling times enable the moulding of high-precision and complex shaped parts.

Cooling and Ejection

The zinc alloy is cooled and solidified in the mould, with the cooling time depending on the thickness of the part. After cooling, the finished part is ejected from the mould by an ejector mechanism.

Trimming

The finished part is trimmed to remove excess material or defective parts. After trimming zinc alloy parts can be recycled.

Common Zinc Alloy Grades

Common zinc alloy grades include:

1.Zamak 3: Best overall performance, widely used in the automotive and electronics industries.

2.Zamak 5: Higher strength, but slightly less ductile for applications requiring higher hardness.

3.Zamak 7: Better flowability, suitable for thin-walled parts.

AZ series (e.g. AZ91D) : Good corrosion resistance and flowability, suitable for complex parts.

Haichen can select zinc alloy grades and optimise process parameters for your die casting production plan.

This can further improve product quality and production efficiency.

Benefits of using zinc die casting

Zinc Die Casting offers many significant advantages.

These advantages make it ideal for the manufacture of complex, precise and durable metal parts.

Below are the key benefits of zinc die-casting:

- High strength and durability

- Cost Effectiveness

- Dimensional accuracy and surface finish

- Design Flexibility

- Corrosion resistance

- High productivity

- Versatile surface treatment

- Environmental benefits

- Wide range of applications

- Reduced need for secondary processing

High strength and durability

Zinc alloys have excellent mechanical properties, including high strength, high tensile strength and high impact strength.

This allows zinc die castings to withstand high pressures and loads while maintaining their shape and integrity.

Cost Effectiveness

Zinc alloys have a low melting point, high productivity and long tool life.

Zinc die casting is therefore a cost-effective manufacturing method.

Compared to other metal alloys, zinc is less costly, especially in high volume production.

Dimensional accuracy and surface finish

Zinc die casting is capable of producing parts with very high dimensional accuracy and a smooth surface finish.

They can usually be used without further processing.

Dimensional tolerances can be ±0.025mm or less.

Design Flexibility

Zinc alloys allow for the manufacture of parts with complex geometries and thin walls while maintaining good dimensional stability.

This flexibility makes it suitable for a variety of industrial applications such as automotive, electronics and medical devices.

Corrosion resistance

Zinc alloys have excellent corrosion resistance, which makes them particularly suitable for use in application scenarios where they come into contact with corrosive substances.

High productivity

Zinc alloys flow well and cool quickly, allowing for faster mould filling and shorter production cycles.

In addition,hot chamber die casting moulds usually have a longer service life than aluminium or magnesium alloy moulds.

Versatile surface treatment

Zinc die castings can be enhanced in appearance and functionality through a variety of surface treatments such as plating, painting and powder coating.

For example, to improve corrosion resistance and aesthetics.

Environmental benefits

The zinc die casting process produces less waste and the zinc alloy can be recycled, which helps to reduce the environmental impact.

Wide range of applications

Zinc die castings are used in a wide range of industries, including automotive, aerospace, electronics, and medical devices.

Applications range from large structural components to small precision parts.

Reduced need for secondary processing

The high hardness and wear resistance of zinc alloys make them ideal for manufacturing bearings and other parts that require high wear resistance.

This reduces the need for secondary machining.

Zinc die casting occupies an important position in modern manufacturing due to its excellent mechanical properties, cost-effectiveness, high precision and versatility.

It not only meets the needs of various complex designs, but also significantly improves productivity and product quality.

Haichen offers proven and reliable zinc alloy die casting machines.

Established in 2005, Haichen is a professional die casting machine manufacturer with over 20 years of experience in the production of die casting machines.

Its products include cold chamber and hot chamber die casting machines, which are suitable for die casting production of aluminium, zinc, lead and other materials. In addition, Haichen’s equipment design complies with national and EU safety standards, and adopts advanced computer-aided design (CAD/CAE) and finite element analysis technology to ensure that the equipment is structurally sound and operates safely and reliably.

Haichen’s products are exported to many countries and regions, with annual production ranging from 30 to 1,600 tonnes, demonstrating the wide applicability and market acceptance of its equipment.

Haichen also emphasises the efficiency and reliability of its equipment to meet the production needs of its customers.

Please feel free to write to us for more information and let us help you with your production plans.