Adding aluminum to zinc alloys has a number of significant advantages:

- Improved mechanical properties

- Reduced solidification temperature

- Reduced corrosiveness

- Better Weight-to-Strength Ratio

Aluminium can improve mechanical properties, such as strength and hardness, due to aluminum’s solution strengthening and grain refinement.

In addition to this, there are also aspects such as fluidity and corrosion resistance.

Among them, when the addition amount of aluminum is 2-4%, the tensile strength and elongation are the best, but more than 6% will decrease.

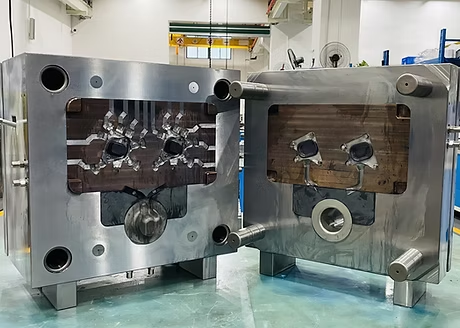

This helps with casting performance, especially in the die casting process, which is easier to shape and get castings with smooth surfaces.

In addition, aluminum can form an oxide film, especially in the coating, and the corrosion resistance is better when the aluminum content is higher.

At the same time, aluminum also reduces the erosion of iron by zinc, which is good for mold life.

What is Zinc Alloy?

Zinc alloys are mostly zinc, but they also have small amounts of other metals like aluminum, magnesium, and copper mixed in.

These additions make the zinc stronger, more flexible, and less likely to rust.

For example, adding aluminum makes the zinc harder, while magnesium helps it resist bending over time.

Improved mechanical properties

The addition of aluminum can significantly enhance the strength and hardness of zinc alloys.

When the aluminum content is between 3.9% and 4.3%, the strength and impact value of the alloy reach its best.

In addition, aluminum refines the grains, which improves the overall mechanical properties of the alloy.

Aluminum improves the fluidity of Zink legering, making them easier to die-cast.

At 5% aluminum, the alloy has the best flowability.

Which helps to produce precision parts with smooth surfaces and complex shapes.

Reduced solidification temperature

The addition of aluminum lowers the solidification temperature of the zinc alloy, allowing the alloy to solidify at a lower temperature, thereby reducing the risk of hot cracking.

Reduced corrosiveness

Aluminum reduces the reaction rate between zinc and iron, reducing the ability of Zink legering to corrode iron materials, thereby extending the service life of molds and equipment.

Better Weight-to-Strength Ratio

For mass, alloyed metals can be less dense than pure metals while maintaining the same strength.

The automotive and aerospace industries prize aluminum and titanium alloys for their lightweight strength.

Alloy properties

The specific properties of alloys depend on the metals used to manufacture them.

For instance, when aluminium is mixed with zinc, the resulting alloy not only has the luster of gold but also enhances the strength of aluminium.

Alloys are more corrosion-resistant, stronger, easier to process and less costly than pure metals.

Factors such as the composition of an alloy or its production method can affect its ductility, brittleness and machinability.

Specific Effect of Aluminum on the Solidification

- Temperature of Zinc Alloys Improve the fluidity of the alloy

- How to optimize the solidification process by adding aluminum to zinc alloys?

Temperature of Zinc Alloys Improve the fluidity of the alloy

Aluminium materiaal is a common added element in zinc alloys.

Which can improve the fluidity of the alloy and improve the mechanical properties of the alloy in a large range.

High-alumina-zinc-based alloys (such as ZA series) have a wide range of solidification temperatures, and the solidification method is paste solidification.

Zinc alloys with higher Aluminium materiaal content (such as ZA-27) have the widest solidification temperature, and dendrite segregation and regional segregation are the most severe.

How to optimize the solidification process by adding aluminum to zinc alloys?

An increase in the aluminum content leads to a wider range of solidification temperatures for zinc alloys, resulting in longer solidification times.

The fluidity of high-alumina-zinc alloys is comparable to that of aluminum-silicon alloys, but they are prone to bottom cratering.

which is related to the aluminum content.

The heat treatment process can refine the structure of zinc-aluminum-zinc alloy and improve its strength and toughness.

Advantages of adding aluminum to zinc alloys at high temperatures

Zink-aluminiumlegering perform well in high-temperature environments, especially at temperatures above 200 degrees Fahrenheit.

The self-healing ability of Zink-aluminiumlegering allows them to maintain a long service life even after external corrosion.

In addition, the passivation film produced by the aluminum-zinc alloy at high temperature can effectively block the dissolution-redeposition process of active elements such as zinc and indium, thereby enhancing its corrosion resistance.

In contrast, other alloys such as aluminum alloys are easily passivated at high temperatures, but their passivation effect is not as obvious as that of aluminum-zinc alloys.

Aluminum-zinc alloy also has good heat resistance and oxidation resistance, making it more stable in high-temperature environments.

For example, it does not change color for a long time at 300°C, and can be used for a long time at about 500°C.

These properties make aluminum-zinc alloys ideal materials for making corrosion-resistant devices such as automotive mufflers and exhaust pipes.

Haichen‘s die casting experience

The addition of aluminum not only improves the mechanical properties and casting properties of zinc alloys.

But also enhances their corrosion resistance, making it have a wider application prospect in industrial applications.