The benefits of using robots in die casting production are obvious. Robots can work tirelessly without making mistakes, ensuring high precision and consistency in producing parts that meet specifications.

When it comes to die casting, robots are typically utilized to reduce costs and speed up production. This is particularly true in high-volume die casting where the work can be almost completely automated with a single human overseer. Robots are both widely used in the die casting industry to produce products and are themselves produced by being cast.

Excessive heat, molten alloys, dust particles, noise pollution, and fumes can make foundry environments uncomfortable and unsafe for personnel, but they can be ideal for robots. Die casting applications are among the ideal tasks for foundries to automate using robots.

The Benefits of Automating the Die-Casting Process

Improve safety: Replace manual work to perform dangerous tasks such as high temperature and contact with molten metal, and reduce the risk of work-related injuries.

- Improve efficiency and consistency

- Reduce costs

- Enhance flexibility

- Improve quality

- Data-driven optimization

Improve efficiency and consistency

The robot can operate 24 hours a day, reduce cycle time, ensure process stability (such as spraying, pouring, trimming, etc.), and reduce scrap rate.

Reduce costs

Automation robotic casting reduces manpower requirements and saves labor costs; at the same time, it optimizes material use and energy efficiency to reduce total production costs.

Enhance flexibility

Collaborative robots (cobots) are combined with traditional robots to adapt to diverse tasks (such as precision trimming and quality inspection) and quickly respond to changes in production needs.

Improve quality

Reduce human errors and improve casting consistency and pass rate through precise operation and real-time data monitoring (such as sensor detection).

Data-driven optimization

The automation system can collect production data for continuous process improvement, early identification of defects, and overall efficiency.

These advantages have jointly promoted the die-casting industry to develop in an efficient, safe and sustainable direction.

Benefits of using a die-casting robot

- Improved Efficiency

- Higher Quality Part Production

- Increased Worker Safety

- Greater Flexibility

- Reduced Labor Costs

- Data Collection

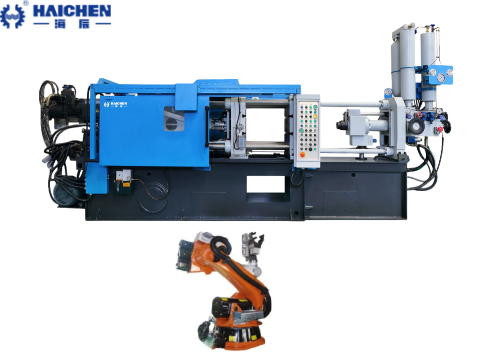

On Our Haichen experience each die casting manufacturer can program robots to perform a variety of tasks and adapt to different production scenarios, enabling them to quickly respond to changing customer needs or production plans, increasing flexibility and competitiveness.

Die casting robots can work tirelessly with few mistakes, ensuring high precision and consistency when producing parts that meet specifications.

These advantages are that the use of robots to automate die casting applications can increase production, shorten cycle time, reduce costs and improve customer satisfaction, which is a necessary technology upgrade for die casting manufacturers looking to improve operations.

Key considerations when choosing a die-casting robot

Choosing the right die casting robot depends on several factors relevant to the production of your die casting products.

- Payload considerations

- Reach area

- Robots in die casting compatibility issues

- Robot programming ease

- Affordability

Payload considerations

How much weight can it handle? Make sure your die casting robot can lift and manipulate the heaviest parts with ease.

Reach area

Is its arm long enough to reach all areas of the die casting machine? If your robot doesn’t have enough reach, your operation will be meaningless.

Robots in die casting compatibility issues

Your new robot needs to integrate perfectly with your current setup. Double-check compatibility with existing die casting equipment to avoid costly mistakes and downtime.

Robot programming ease

Understand the programming capabilities of the robot. You need a die casting robot that is smart enough to handle complex tasks, but user-friendly enough, and intelligent built-in programs are necessary.

Affordability

While die casting robots vary in price, focus on their long-term value, not just the upfront cost. A more powerful robot may save you money in the long run.

Haichen provides automation solutions for each stage of die casting production.

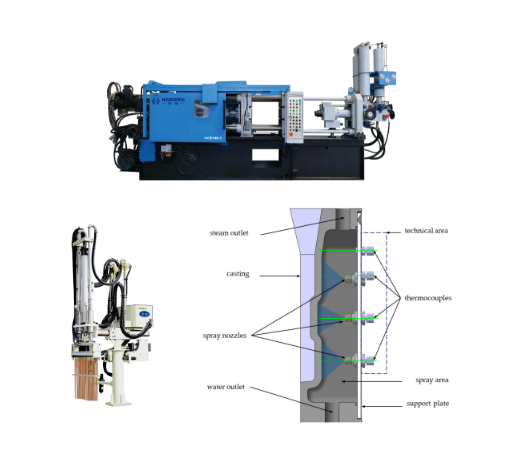

Ladle robots are used to feed raw materials into the pressure chamber.

Automatic spraying robots are used to cool the mold cavity and accelerate the production cycle.

Automatic part-retrieving robots are used to remove finished products and move them to the hydraulic trimming system.

Haichen offers a variety of multi-functional robots to help you produce high-quality parts with exceptional surface finish and extremely high precision. Many parts require up to 90% metal removal, making the performance of the casting process crucial. Haichen’s casting robots shorten cycle times, thereby reducing part costs, increasing processing capacity, and eliminating the need for new equipment, thus avoiding increased operating costs.