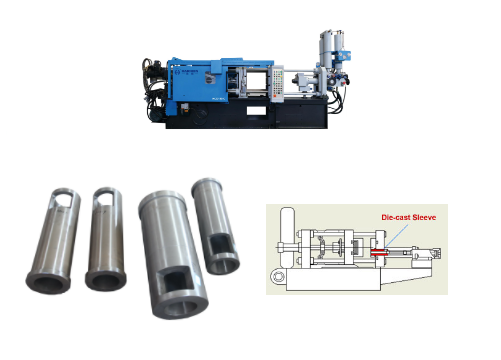

Die casting machine shot sleeves benefits include improve production efficiency and tool life, control temperature and defect reduction, etc.

The die casting machine shot sleeves achieves improved production efficiency. Also with extended mold life (anti-wear, anti-deformation) through material innovation (H13 steel + coating). Thermal management (preheating + cooling), geometric optimization (conical cavity + vacuum seal) and maintenance strategy (modular replacement + refurbishment).

The die casting machine shot sleeves significantly reduces maintenance frequency. With material costs and downtime losses through four core advantages: modular design, high-performance materials, precise thermal management and replaceable components.

Shot Sleeves for die casting machines have the following main advantages:

- Improve production efficiency and tool life

- Temperature control and defect reduction

- Reduce deformation caused by thermal expansion

- Improve casting quality of die casting machine shot sleeves benefits

- Reduced maintenance costs

- Adapt to different production needs

Improve production efficiency and tool life

High-quality die casting machine shot sleeve can ensure stable performance in high temperature. And high pressure environments through optimized design and material selection. For example, some shot sleeves are designed with replaceable cores. They can maintain optimal performance even in the event of corrosion. Or cracks in the inner hole, while reducing maintenance costs.

- Optimize metal flow and filling control

- Reduce scrap rate and downtime

- Extend mold life: Material and surface treatment enhance durability

- Thermal management reduces deformation

- Structural optimization reduces wear

Optimize metal flow and filling control

The die casting machine shot sleeve reduces turbulence. To ensure that the molten metal fills the mold stably. Shorten the filling time through precise geometric design (such as diameter, length, taper) and cooling system.

- For example, the conical expansion of the inner cavity design (the cross section expands 2-8% toward the front end) can accommodate oxide impurities. Avoid blocking the flow channel. At the same time, it forms a conical material handle (biscuit). That is easy to eject and reduces ejection energy consumption.

- Four-stage injection control (slow speed-first, fast-second, fast-pressurization) realizes linear precision injection molding. That increases injection speed by 30%, and shortens cycle time.

Reduce scrap rate and downtime

Temperature control (water cooling/oil cooling system) maintains uniform shot sleeve temperature.

- It avoids premature solidification or thermal expansion deformation of molten metal, and reduces defects such as porosity and cold shut.

- For example, the barrel life of the integrated cooling water channel is increased from 20,000 times to 63,482 times. Significantly reduce the frequency of downtime maintenance.

- Vacuum design (such as spring bushing closed gap) prevents air from being drawn in. Reduce casting porosity, and reduces scrap rate.

Extend mold life: Material and surface treatment enhance durability

- Use H13 tool steel (NADCA certified), hardness 45-60 HRC, resistant to 700°C high temperature and molten metal corrosion.

- Titanium-based composites further extend tool life and reduce thermal fatigue cracks.

Thermal management reduces deformation

- The cooling system controls the temperature evenly to avoid local overheating of the barrel and ovalization. For example, the temperature-regulated barrel delayed the occurrence of plunger jamming from 5,000 times to 46,486 times.

- Preheating the barrel eliminates startup scrap, stabilizes the thermal expansion coefficient, ensures that the gap between the plunger and the barrel is ≤ 0.004 inches, and prevents flash and abnormal wear.

Structural optimization reduces wear

- Replaceable bushing design (such as 25,000 core life and 1,000,000 shell life) only replaces worn parts, reducing overall replacement costs.

- Conical mating surface (piston front end and barrel) reduces metal residue and impurities entering the mold and protects the mold flow channel.

Benefits of Shot Sleeves for die casting machine: Temperature control and defect reduction

- Maintaining Molten Metal Fluidity

- Preheating function reduces start-up scrap

- Reduce porosity and flow marks

- Prevent cold shuts and incomplete filling

The design of the barrel helps maintain the temperature of the molten metal, thereby ensuring proper filling of the mold cavity and reducing casting defects. For example, through the design of the water circulation system, the barrel can achieve uniform cooling, extend service life and maintain optimal performance.

In addition, pre-curing treatment of the barrel also helps improve the microstructure and casting properties.

Maintaining Molten Metal Fluidity

- Uniform cooling of the barrel through a water or oil circulation system (such as a water cooling channel or oil temperature control unit) ensures that the molten metal maintains a stable temperature before being injected into the mold to avoid premature solidification or loss of fluidity.

- Example: Targeted cooling of the bottom of the barrel can control the temperature difference within 90°F (50°C) to prevent deformation of the barrel (such as ovalization) due to thermal expansion.

Preheating function reduces start-up scrap

- Preheating the barrel to 600–800°F (315–427°C) can establish near-isothermal conditions, eliminate temperature fluctuations in the early stages of production, and significantly reduce start-up scrap rates (especially for high-cost alloys).

- Example: After preheating, the temperature distribution of the barrel is more uniform, reducing incomplete filling or cold shut defects caused by cold starts.

Reduce porosity and flow marks

- Optimizing the geometry of the barrel (such as taper design) and controlling the slow injection stage can reduce molten turbulence and reduce the risk of air entrainment, thereby reducing the porosity of the casting.

- Technology: Vacuum-assisted die casting technique with barrel sealing design can reduce porosity defects by more than 35% and improve the density and strength of castings.

Prevent cold shuts and incomplete filling

Stabilize the barrel temperature to ensure consistent melt viscosity and avoid solidification of the melt front (cold shuts) or incomplete cavity filling due to local overcooling.

Example: Coordinated control of mold temperature and barrel temperature (such as using a temperature control unit) can reduce cold shut defects by 18–22%.

Haichen produce durable die casting machine chamber helps maintain the temperature control of the molten metal. Ensure the proper filling of the mold cavity and reducing casting defects. As Haichen is one Chinese manufactuer who produce die casting machine and spare parts for more than 10years. With rich experience and strict production control, Haichen produce and supply different grade and series shot sleeves to meet customer’s die casting production demand.

Reduce deformation caused by thermal expansion

- Control temperature differences through cooling system design

- Optimize wall thickness and material selection

- Compensation design for thermal expansion coefficient

The wall thickness and cooling design of the barrel can effectively reduce the ovalization or distortion caused by thermal expansion. For example, by controlling the cooling temperature at the bottom of the barrel, it can avoid deformation caused by large temperature differences.

Control temperature differences through cooling system design

Cooling the bottom of the barrel can reduce deformation caused by temperature gradients. Evidence clearly shows that the temperature difference between the bottom and the top needs to be controlled within 90°F° (50°C°), otherwise excessive expansion in the hot area (usually below the pouring gate) will cause barrel ovality or bowing.

- This deformation will increase the friction between the plunger tip and the inner wall of the barrel, causing abnormal wear and seizure.

- The choice of cooling medium (water or oil) depends on the process requirements: oil also has a heating function, which can preheat the barrel to reduce cold start wear.

Optimize wall thickness and material selection

Wall thickness design needs to balance heat capacity and heat dissipation efficiency.

- Too thick wall thickness will accumulate too much heat and aggravate overall expansion; too thin wall thickness will easily cause local deformation.

- For example: when the wall thickness is insufficient, the pouring gate will be too large and will directly cause deformation.

- Application of high-performance materials (such as H13 steel)

- H13 steel has excellent thermal fatigue resistance and hardness (45-60HRC), and combined with surface treatments such as nitriding, it can enhance wear resistance and inhibit thermal deformation.

- Emphasis on strict heat treatment specifications and high-precision processing can minimize deformation.

Compensation design for thermal expansion coefficient

- The thermal expansion of a large diameter barrel is more significant (for example, a 6-inch barrel expands twice as much as a 3-inch barrel), so stricter temperature control is required.

- Segmented barrel design: The two-stage barrel (pour end section can be replaced separately) can replace the damaged part of the high-temperature area in a targeted manner, reducing the overall deformation risk and maintenance costs.

Improve casting quality of die casting machine shot sleeves benefits

- Reducing turbulence and porosity

- Vacuum-assisted technology

- Uniform Cooling and Thermal Deformation Control

- Preheating reduces start-up scrap

The barrel is the key channel between the molten metal and the mold, and its design directly affects the surface quality and internal defects of the casting. For example, by optimizing the geometry and cooling path of the barrel, that can reduce defects such as flow lines.

Reducing turbulence and porosity

Barrel design (e.g., geometry and taper) can stabilize molten metal flow and reduce air entrapment caused by turbulence. Optimizing barrel geometry and cooling paths can reduce defects such as flow lines.

Vacuum-assisted technology

An annular plunger tip design (e.g., spring bushing) closes the gap between the barrel and plunger, reducing air ingestion and significantly reducing casting porosity. This design achieves high vacuum levels and reduces porosity.

Uniform Cooling and Thermal Deformation Control

A built-in water or oil cooling system in the barrel maintains metal temperature stability (ΔT < 15°C), preventing premature solidification and thermal deformation.

Preheating reduces start-up scrap

Preheating the barrel has been shown to eliminate scrap during the initial production phase, which is especially critical for high-cost alloys.

Reduce maintenance costs

- Modular Design and Replaceable Components

- Materials and Processing for Extended Service Life

- Defect Prevention of Die casting machine shot sleeves benefits

High-quality barrels are usually made of high-temperature and corrosion-resistant materials and are designed to be easily replaced. For example, the inner core of some barrels can be reused up to 25,000 times, while the outer shell life exceeds 1,000,000 times, significantly reducing maintenance costs.

Modular Design and Replaceable Components

The split barrel design allows replacement of only the removable sleeve when worn, eliminating the need for complete replacement. This significantly reduces material costs and downtime, as the fixed sleeve remains in place for extended periods, requiring only the worn portion, representing one-third of the total length, to be replaced. For example:

- Material Savings: Reusable steel for the fixed sleeve reduces material waste by over 40%.

- Maintenance Efficiency: Replacement time is reduced by over 60%, eliminating mold and platform disassembly.

Materials and Processing for Extended Service Life

High-Performance Materials: emphasize the use of high-temperature-resistant steels such as H13/SKD61 (hardness 45-60 HRC). Combined with nitriding or ceramic coatings (such as TiN) to significantly enhance corrosion and wear resistance.

Defect Prevention of Die casting machine shot sleeves benefits

Preheating the barrel eliminates startup scrap, which can lead to unnecessary maintenance and lost production.

Adapt to different production needs

The design of the barrel can be adjusted according to different production needs. For example, in horizontal and vertical die casting machines, the design and cooling methods of the barrel are different to adapt to different production environments.

Benefits of Shot Sleeves for die casting machine not only improves production efficiency and casting quality, but also extends tool life and reduces maintenance costs by optimizing design, material selection and cooling system.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.