Common Issues of Plunger Ring for die casting

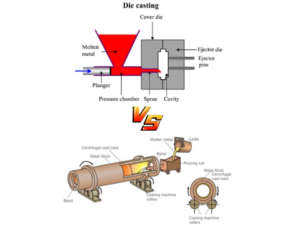

Plunger Ring Issues in Die Casting include wear and tear, thermal fatigue, and material buildup, which can lead to reduced sealing efficiency, increased metal leakage, and inconsistent shot volumes. In

Plunger Ring Issues in Die Casting include wear and tear, thermal fatigue, and material buildup, which can lead to reduced sealing efficiency, increased metal leakage, and inconsistent shot volumes. In

Graphite crucibles and ceramic crucibles each have their own advantages and disadvantages,there is no absolute “better”. The choice depends on specific application requirements, such as temperature, environment, material type and

Crucible for melting aluminum includes high temperature resistance, chemical stability, corrosion resistance and others. Crucibles for melting aluminum usually made of alumina, graphite or ceramic materials because of their excellent high temperature

Die casting crucibles are key components in die-cast furnaces, applied for the melting and holding of metals such as aluminum, zinc, or magnesium. Proper replacement and installation guarantee safe operation,

Crucible Materials include graphite, ceramic, silicon carbide and steel and cast iron. Crucibles play a vital role in various industrial and laboratory processes, particularly in melting and heating materials at

The Crucible Selection Guide offers vital advice on picking the appropriate crucible, which is key to maintaining efficiency and ensuring high – quality results in die – casting processes. In

Nozzle manufacturers in die casting in China are mainly concentrated in the Pearl River Delta and Yangtze River Delta regions. Actually,die casting nozzles are essential die casting parts for die

Replacement nozzles for die casting machines are critical components that ensure efficient molten metal transfer from the shot sleeve to the mold cavity. Their design, material, and compatibility directly impact

In die casting, nozzles play a crucial role in the injection system, which is responsible for delivering molten metal into the die cavity. This article will detail the specific roles

Nozzles in die casting offer several advantages, including precise control over molten metal flow, improved filling of complex mold cavities, reduced defects, and enhanced overall part quality and production efficiency.