Why die casting is used?

Die casting used reason includes efficient production of parts with complex geometries, suitable for mass production and so on. Why die casting is used? Because die casting is an efficient

Die casting used reason includes efficient production of parts with complex geometries, suitable for mass production and so on. Why die casting is used? Because die casting is an efficient

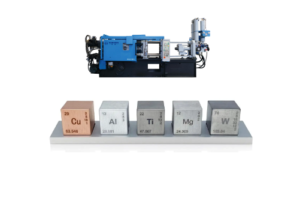

Metallic Lightweight Materials Market continues to grow, driven by both environmental policies and technological innovations. With the Asia-Pacific region becoming the growth engine, while high-end applications such as aerospace titanium

Metallic lightweight materials offer several benefits, including improved fuel efficiency, enhanced performance, reduced environmental impact, and increased design flexibility, making them ideal for modern manufacturing applications. In the die –

Metallic lightweight materials properties and production includes main types, production methods, microstructure and so on. Metallic lightweight materials have the characteristics of low density and high strength. They widely use in

Selecting the right metallic lightweight materials requires a comprehensive analysis of material properties, cost, manufacturability, application requirements, and environmental impact. Lightweight metals constitute a category of materials characterised by high strength and

Application of metallic lightweight materials such as aluminum and magnesium alloys: Widely used in the automotive, aerospace, and consumer electronics industries to reduce weight, improve fuel efficiency, and enhance performance

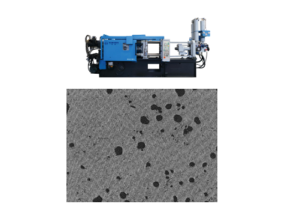

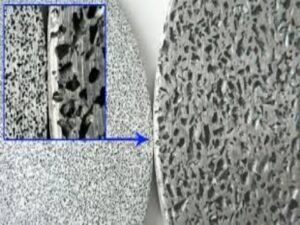

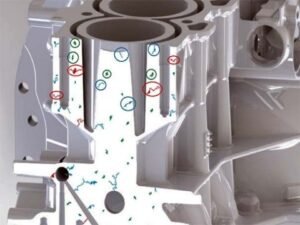

To reduce porosity in die casting through the systematic integration of process parameter optimization, mold venting design, vacuum/degassing technology, and numerical simulation. Reducing porosity in die casting is crucial for

Gas Porosity refers to the bubbles or holes formed when the gas in the molten metal does not completely escape and solidifies during the die casting process. Gas Porosity Morphology

Shrinkage defects are those cavities inside the parts that reduce strength; if they are on the surface, they reduce aesthetics and corrosion resistance. It is also very important to be

Porosity in die casting is primarily caused by trapped air or gas within the mold cavity, improper gating and venting designs, insufficient compaction of the molten metal, and variations in