What is the purpose of a conveyor in die casting

The purpose of a conveyor in die casting is to automate part transfer, improve efficiency, and ensure safe handling of castings. In the die – casting industry, conveyors play a

The purpose of a conveyor in die casting is to automate part transfer, improve efficiency, and ensure safe handling of castings. In the die – casting industry, conveyors play a

Die Casting Sprayer failure include : For instance, if the spray gun leaks paint, this issue often arises either because improper installation has left the gun needle sealing ring loose.

The main functions of the sprayer in die casting are lubrication of the mold, cooling, and demolding. Types include automatic, servo, two-axis, internal spraying, etc. The technical features include precise

Technical Parameter of Sprayers in Die Casting includes spraying method and automation, spray coating materials and processes, etc. Automated spraying reduces labor costs, improves production efficiency, and reduces casting defect

Die casting spray machine price is about $7000-$11500. But the price of die-casting spray machines can vary significantly based on their features, capacity, and automation level. A die casting spray machine is

Spraying technology for high pressure die casting ensures optimal mold lubrication and cooling for consistent casting quality. Manufacturers widely employ high pressure die casting (HPDC) to produce precision metal parts

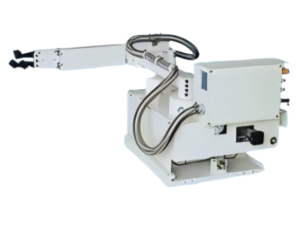

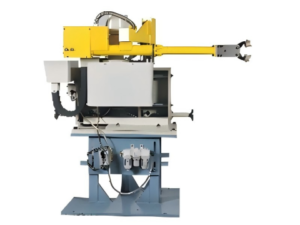

An Auto Extractor for a die casting machine is a device designed to automatically remove castings from the die after the casting cycle is complete. It improves efficiency, reduces manual labor, and

Die casting machine and Auto Extractor represents the core direction of the transformation of the precision casting field to automation and intelligence. The synergy between the two not only significantly

An extractor is a mechanical device in die casting that is used to enter between the two halves of the mold after the mold is opened, clamp the casting, pull

Automatic Extractor Used for Die Casting Molds efficiently removes castings with precision, reducing cycle time and manual handling risks. In the die casting industry, the efficiency and precision of mold