Die casting machine brands of aluminum alloy road nail die-casting machine are both domestic:

- L.K. Technology

- Yizumi

- Haitian Metal

- Haichen

- Hongtu

- Bühler Technology Status

- Toshiba Machine

And international well-known brands, and they have different technical advantages and market leadership.

Die casting machine brands–L.K. Technology

China’s largest die-casting machine manufacturer, with a leading global market share, with a market share of nearly 50% in 2020.

Technical features

Covering hot chamber and cold chamber die-casting machines, cold chamber models are especially suitable for high melting point alloys.

Such as aluminum alloys, which are widely used in auto parts manufacturing.

It took the lead in launching ultra-large die-casting machines (such as 6000T, 8000T).

And cooperated with Tesla to develop integrated die-casting equipment.

The equipment has a high shot capacity, numerical control and modular design.

And supports precision die casting of small and medium-sized parts.

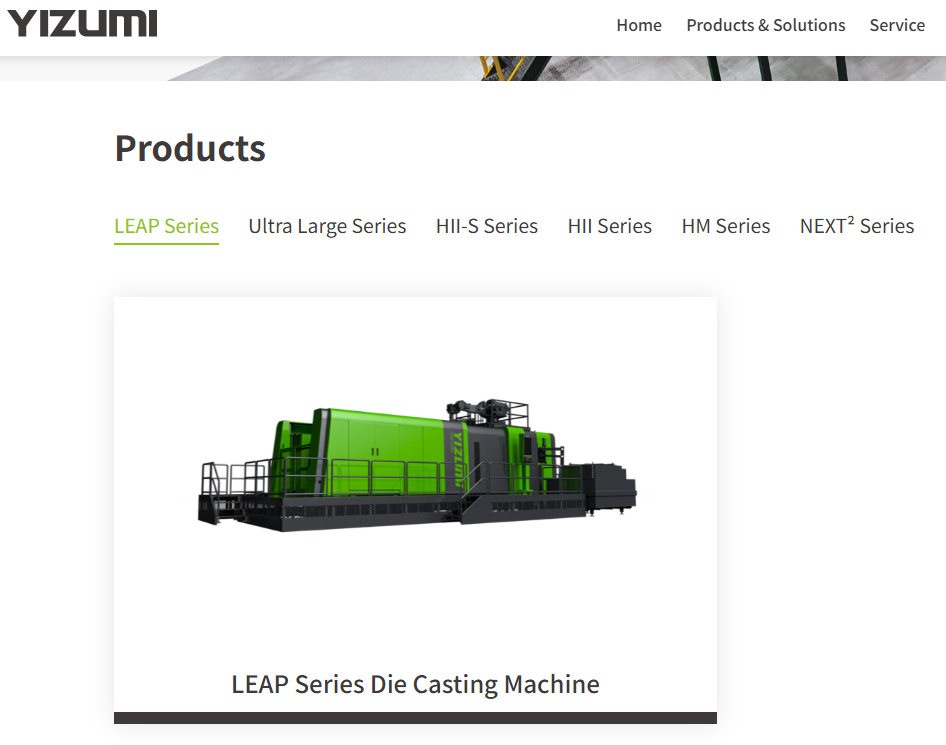

Die casting machine brands–Yizumi

The second largest die-casting machine manufacturer in China, with a market share of about 8.4%, focusing on molding equipment.

Technical features

The LEAP series die-casting machine supports a clamping force of up to 9000T.

To meet the needs of ultra-large integrated die-casting of new energy vehicles.

The product line covers cold chamber and hot chamber models.

Taking into account the production efficiency and accuracy of small and medium-sized aluminum alloy parts.

Provide intelligent control system, suitable for mass production of complex structural parts.

Die casting machine brands–Haitian Metal

In fact, haitian has the manufacturing capacity of large-scale die-casting machines of more than 6000T.

Which forms a technological competition with LK and Yizumi.

The equipment is known for its high stability and energy-saving characteristics.

And is suitable for the continuous production of small and medium-sized parts such as aluminum alloy road studs.

Haichen die casting machine

Ningbo Haichen machinery was founded in 2005, Located in Ningbo, Zhejiang, China.

HAICHEN specializes in the production and sale of hot chamber die-casting machines, cold chamberdie-casting machines.

Besides,servo die casting machines, magnesium alloy die casting machines and relative auxiliary equipment.

We always places more emphasis on the technology and management.

Because of its advanced technology, high quality and effective management.

HAlCHEN’s hot chamber as well ascold chamber die-casting machines has won the trust from our clients at home and abroad.

Guangdong Hongtu

Although is mainly engaged in the production of die-casting parts.

It has developed its own 12000T die-casting equipment to promote super-large integrated die-casting technology.

Through the purchase of die-casting machines of brands such as LK.

The production line including small and medium-sized aluminum alloy parts.

Bühler Technology Status

The global technology benchmark in the die casting machine industry.

Cold chamber die casting machines have advantages in the field of precision parts.

It is suitable for the production of high-precision aluminum alloy road studs.

But the equipment purchase and maintenance cost is high.

Toshiba Machine

Toshiba Machine Co., Ltd. is a subsidiary of the Toshiba Group of Japan.

Founded in 1938 and headquartered in Numazu City, Shizuoka Prefecture, Japan.

The Company is mainly engaged in the research and development.

Manufacturing and sales of injection molding machines, hot and cold die-casting machines.

Extruders, printing machines, machine tools, machining centers, high-precision machine tools.

Micro-pattern imprint electronic controls, semiconductor production equipment and other large-scale machinery.

BUHLER Die casting machine

As a global leader in die casting technology, BUHLER’s die casting machines are known for their high precision, high stability and innovative technology.

Since its foundation in 1860, the company has accumulated more than 160 years of experience.

In the field of die casting, especially in large-scale integrated die casting solutions.

The key parameters for selecting a die-casting machine

Clamping force range

Road nails are small and medium-sized parts, usually requiring a die-casting machine below 3000kN, and domestic equipment accounts for 60%.

Cold chamber die casting technology

Aluminum alloy has a high melting point (about 660°C), and the cold chamber die casting machine is more suitable for its production.

Avoiding corrosion caused by direct contact between molten metal and the injection system.

Automation and precision

Modern die-casting machines are often equipped with CNC systems (such as LK’s H series).

Which support parameter memory and quick mold switching to improve production efficiency.

Die casting machine industry development trend

Lightweight demand driven

The demand for aluminum alloy parts in the automotive and transportation fields has increased.

Promoting the development of die-casting machines in the direction of high precision and high efficiency.

Technology upgrading

The application of new processes such as vacuum die-casting.

And semi-solid die-casting further improves the compactness and mechanical properties of aluminum alloy parts.

Aluminium alloy road studs die casting machine

It is a special die-casting equipment used to produce aluminum alloy road protrusion road signs.

Definition

Aluminum alloy road protrusion road sign die casting machine is a kind of mechanical equipment.

That injects molten aluminum alloy into a steel mold cavity through high pressure to produce complex shapes and high-precision parts.

The equipment typically includes core components such as a shot system, a tooling system.

And a cooling system to efficiently and accurately manufacture aluminum alloy die castings.

Die Casting Machine Uses

Production of Aluminum Alloy Road Protrusion Road Signs

This equipment is mainly used to produce aluminum alloy protruding road signs for traffic signs and road safety.

These road signs are lightweight, high-strength, corrosion-resistant.

And highly abrasion-resistant, making them suitable for a variety of road environments.

Efficient production

Aluminum alloy die-casting machine is able to quickly produce a large number of high-quality parts, which is suitable for large-scale industrial production.

Precision Manufacturing

Through high-pressure injection and rapid cooling.

The equipment is able to produce parts with high dimensional accuracy and good surface quality, reducing the need for subsequent processing.

Wide application

In addition to road protrusion road signs, aluminum alloy die-casting machines.

Are also widely used in auto parts, electronic equipment, home appliance shells and other fields.