The brands of controller of the die casting machine includes:

- Siemens

- Rockwell Automation

- Mitsubishi

- Toshiba

- Schneider

- Beckhoff

- Panasonic

- Omron

- Yaskawa

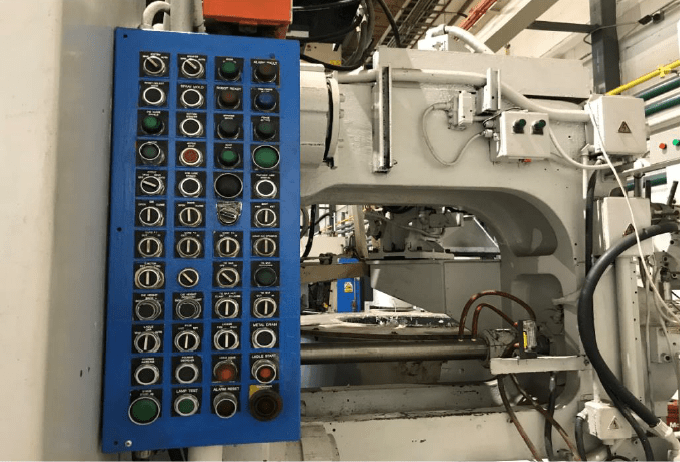

The Die casting machine controller is an electronic device used to control and manage the entire production process of the die casting machine.

It ensures the stable operation of the die-casting machine under the set parameters by receiving signals from sensors and executing corresponding control logic.

These controller brands play a vital role in the die casting machine, ensuring the efficiency.

And quality control of the die casting process through advanced technology and user-friendly interface.

Siemens

The S7-200/S7-300 series PLCS are used for basic action control supporting digital/analog input.

And output, and processing signals such as injection position and pressure feedback.

S7-1500 series PLC (high-end models) : Nanosecond-level computing speed, supports distributed IO control, and achieves ±0.01mm pressure ejaculation.

Siemens’ PLC can achieve high-speed data acquisition,Haichen also uses Siemens controller.

The SM335 module can collect the injection pressure and position curve in real time with an accuracy of 0.3ms, meeting the closed-loop control requirements of 10m/s high-speed injection.

Meanwhile, it is compatible with multiple protocols and integrates the Profinet standard interface.

Seamlessly connecting with peripheral devices such as spraying robots and soup feeding systems.

Rockwell Automation

Is a globally leading provider of industrial automation and digital transformation solutions, founded in 1903, with its headquarters located in Milwaukee, Wisconsin, USA.

Rockwell Automation’s intelligent devices division offers products such as drives, motion control, safety, sensing and industrial components.

In addition, the company also provides industrial networks, power supply devices, sensors, operator interfaces, communication products, etc.

Rockwell Automation is committed to helping customers enhance productivity, efficiency and sustainability through technological innovation and domain expertise.

Mitsubishi

The PLC product line of Mitsubishi Electric is widely used in the field of industrial automation, providing various models.

And functions to meet the automation requirements of different scales and complexities.

The Mitsubishi MELSEC iQ series PLCS perform well in terms of high-speed processing, built-in functions, network communication, safety and modular design.

And are suitable for industrial automation applications ranging from small to large-scale.

Toshiba

Toshiba PLC is a digital operation electronic system specially designed for industrial environments.

It performs operations such as logical operations, sequential control, timing, counting and arithmetic operations through programmable memory to achieve the automatic control of mechanical equipment or production processes.

The V200 series is one of Toshiba’s main PLC series and is suitable for a variety of industrial automation applications.

This series of PLCS have high-speed processing capabilities, support multiple I/O modules.

Such as PWM output and HS I/P, and support Modbus and master-slave network communication.

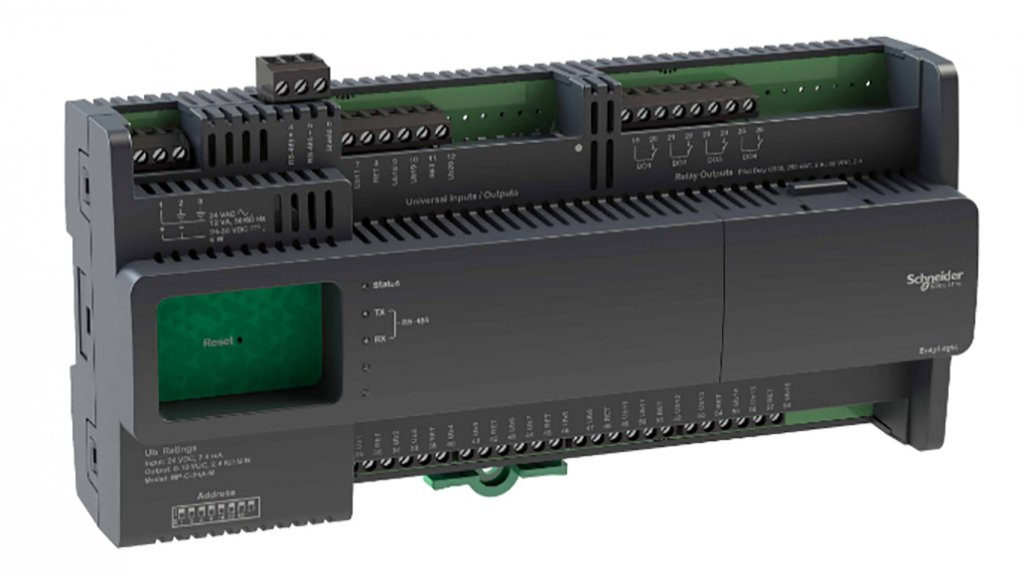

Schneider

Schneider’s PLC products include series such as Zelio, Twido, Modicon M171/M172, M221, M241, M262, etc.

Each series is designed for different application scenarios and budgets.

For example, the Zelio series is a basic type of PLC, suitable for small-scale systems.

The M262 series, on the other hand, is equipped with Internet of Things (IoT) capabilities and supports connection to cloud platforms.

Beckhoff

Beckhoff’s TwinCAT automation software is one of its core technologies.

It integrates functions such as PLC, motion control, safety features, human-machine interface (HMI).

And data acquisition on a single platform, achieving a high degree of flexibility and scalability.

In addition, Beckhoff has developed EtherCAT real-time Ethernet technology.

Which is a high-performance industrial communication protocol widely used in high-speed control fields.

Brands of controller–Panasonic

Panasonic’s positioning in the PLC market mainly focuses on small and medium-sized PLC products.

Its products are characterized by high efficiency, stability, ease of operation and powerful network functions, and are widely used in the field of industrial automation.

Panasonic PLC control systems enjoy a good market reputation in the field of mechanical manufacturing.

Their products have excellent anti-interference capabilities and are suitable for harsh industrial environments.

In addition, Panasonic also offers strong technical support and comprehensive after-sales service to ensure the stable operation of customers’ equipment.

Brands of controller–Omron

Omron, founded in 1933 and headquartered in Kyoto, Japan, is a global leader in the field of industrial automation.

By 2024, our business will cover over 110 countries, with 350 offices and 30,000 employees.

And our annual sales will reach 5.9 billion US dollars.

Its mission is “To improve life and society through automation technology”.

C200Hα series PLC: Memory expansion, improved processing speed, supports PCMCIA card modules, and can realize a “field data processing system”.

CJ series PLC: Modular design (only the size of a playing card), seamless integration of Ethernet /Controller Link is achieved through the FINS protocol, reducing the panel space by 40%.

NX series PLC: Real-time motion control engine, directly synchronizes position/speed/torque, suitable for semiconductor equipment.

Brands of controller–Yaskawa

Yaskawa PLC takes modular design, high real-time performance and multi-protocol compatibility.

As its core advantages, covering the full-scenario requirements from Micro PLC to complex multi-axis systems (MP3000).

The successful application of its technology in the fields of precision manufacturing and energy management, combined with a global service network, has established its benchmark position in the field of industrial automation.

The PLC of haichen die casting machine

Haichen Machinery specializes in the production of die casting machines, provides mold customization services, and sells auxiliary machines and spare parts.

The PLC used in Haichen’s die casting machines is of Siemens brand.

We can also provide customers with other brands as specified.

If needed, please feel free to consult.