Calculating Aluminium HPDC parts cost requires consideration of several factors:

- The price and density of aluminium materials

- Cost of HPDC processing

- Cost of HPDC molds

- Indirect costs and scrap rates of die-castings

- Total cost

In the manufacturing industry, understanding the cost impact of different production processes is crucial for procurement and parts design engineers.

This is especially true for custom die-casting, as it is an efficient and universal manufacturing method.

High-pressure die casting is an efficient technology that produces components with high strength, light weight and requiring less processing than forged parts.

And it can create complex and fine shapes in a single component without assembly or welding.

It offers a wider range of shape options than other metal manufacturing technologies and can help manufacturers achieve extremely high precision requirements.

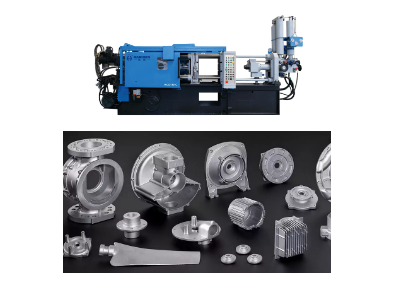

Aluminium Die Casting

Aluminium die casting is a proven process for creating highly accurate, high-quality parts for a variety of applications that precisely meet the design parameters.

Die casted alloys made of aluminium are strong and lightweight, and they offer good dimensional stability for parts with intricate geometries and thin walls.

In comparison to other non-ferrous materials, aluminium die cast parts have more surface finishing options and can sustain higher working temperatures.

Die cast aluminium components have excellent rigidity and strength-to-weight ratios, are highly conductive, and are resistant to corrosion.

What is aluminium HPDC parts?

High-pressure aluminum castings refer to aluminum components that manufacturers produce with high-pressure casting technology.

They boast high precision, high density, excellent mechanical properties and surface quality, and manufacturers apply them widely in the automotive, aerospace and mechanical equipment fields.

Haichen offers high-pressure cold chamber die-casting machines to aluminum die-casting customers. With a professional design team, we can produce precise molds for any type of die-cast parts.

Moreover, we provide after-sales service. If you need online guidance or offline assistance, Haichen is capable of offering it to you.

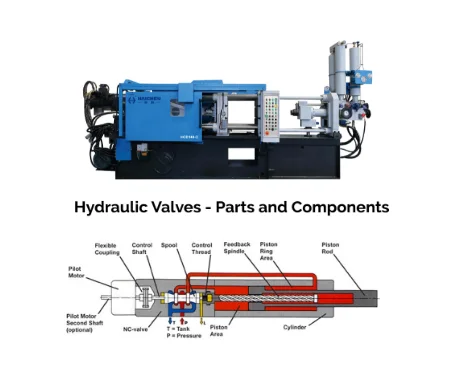

Aluminium die casting process

In the aluminium die casting process, operators heat and fully melt an aluminum bar at high temperature, then force the molten metal into a pre-machined mold cavity to form the required metal parts.

This process adopts the cold chamber of the die casting machine.

On a cold chamber machine, the melting pot is a separate unit, and workers ladle the molten aluminum alloy from the pot into the die—either under gravity or high pressure.

Then, you need to separate the two halves parts of the mold to reveal the aluminum cast part.

You can refer to the case of Haichen for this process.

Raw material cost

The material cost of aluminum alloy is an important part of the cost of HPDC parts.

According to the evidence, the price of aluminum is approximately $1,900 per tonne.

Meanwhile,prices may vary depending on the supplier.

Cost of HPDC processing

- Energy consumption

- Labor costs

- Productivity

Energy consumption

Electricity is the main source of energy consumption in the production of aluminum alloys.

For example, electrolytic aluminum consumes about 13,500 kWh of electricity per tonne.

In the HPDC process, high pressure and rapid cooling also increase energy consumption, but the overall efficiency is higher.

Labor costs

Labor costs include the wages and maintenance expenses of the operators.

Based on evidence, the labor cost per pound of parts is about $0.12.

Productivity

The HPDC process has a high production efficiency and can produce hundreds of parts per hour, which reduces the fixed cost per unit of product.

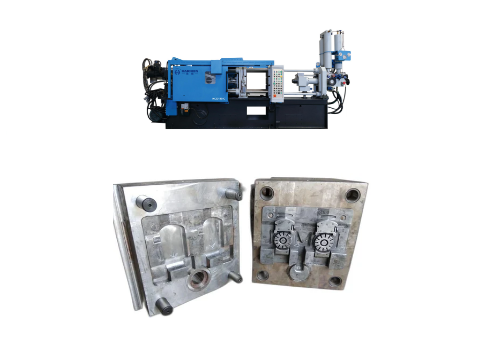

Cost of HPDC molds

The cost of molds ranges from several thousand to several million dollars.

Complex molds (such as the mold for the rear floor of the Tesla Model Y) can reach 500,000 to 2 million dollars.

The lifespan of the mold is approximately 300,000 times and needs to be allocated to the cost per piece.

Maintenance and operation: Mold maintenance costs account for 20% of the total production costs, including welding, repair, downtime losses, etc.

For example, for a 20-pound parts mold with an annual production capacity of 50,000 pieces, the cost per piece is approximately 120 US dollars.

Indirect costs and scrap rates of die-castings

The loss of yield rate, with a porosity rate of 3% to 5%, may lead to defective products and require additional costs for screening.

Total cost

Let’s assume a typical HPDC part weighs 20 pounds, has a mold life of 300,000 injection cycles, and a mold cost of $100,000.

If the price per pound of aluminum is averaged at 27 yuan (about 4 US dollars), the raw material cost is 468 US dollars. Labor costs are $24 ($0.12 per pound).

Let’s assume that the mold depreciation and maintenance expense is 10% of the mold cost, which is 10% of $100,000, or $10,000.