Cast aluminum and cast iron are two common casting materials that differ significantly in many ways.

Cast aluminum is a lightweight, corrosion-resistant metal that heats quickly and uniformly.

Making it ideal for applications like engine parts and cookware that benefit from fast, even heat distribution and reduced weight.

In contrast, cast iron is a heavy, brittle material with excellent heat retention, a naturally dark finish, and a lower cost.

But it requires maintenance to prevent rust and takes longer to heat up, making it better for applications where prolonged heat is desired, like heavy-duty cookware or industrial components.

What is Cast Aluminium?

Casting aluminium is a type of aluminium – it is made by injecting molten aluminium into a mold.

Subsequently, the aluminium cools and solidifies, forming the same shape as the mold.

It is often used to manufacture precise automotive parts, everyday lawn equipment, and furniture, which require strength but also lightness.

If you have any requirements related to die-cast aluminum. Please contact Haichen immediately.

We will provide you with professional guidance tailored to your specific needs!

What is Cast Iron?

On the other hand, cast iron is made by pouring molten iron into a mold or scrap metal.

It is a group of iron-carbon alloys containing more than 2% carbon content.

The alloys are made by mixing iron with scrap metals and materials such as carbon, silicon, and manganese.

This mix is then poured into a mold and allowed to solidify to achieve the desired shape.

Cast iron is known for making items that need to be durable and for its high compressive strength.

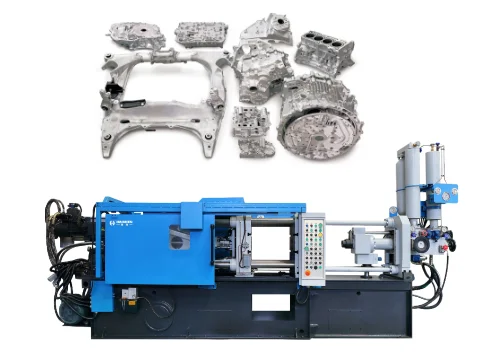

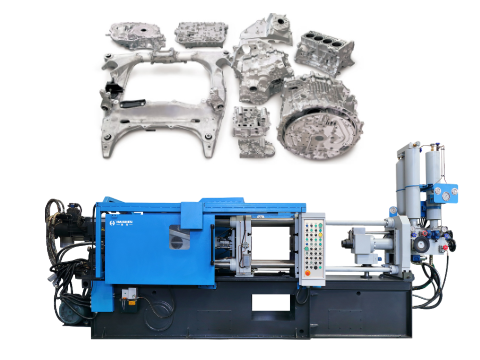

Haichen Aluminum Die Casting

Haichen is a full-service die casting manufacturer who can provide excellent zinc and aluminum die casting services for your specific project requirements.

Die casting is an efficient casting process that uses high pressure to inject molten metal into precision molds, enabling rapid prototyping.

Common cast aluminum grades include A356, A380, and 319, each with different properties like strength, corrosion resistance, and machinability, making them suitable for various casting applications.

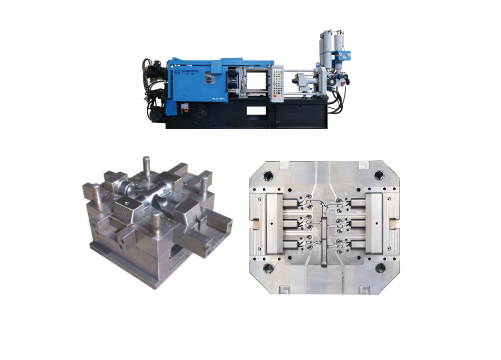

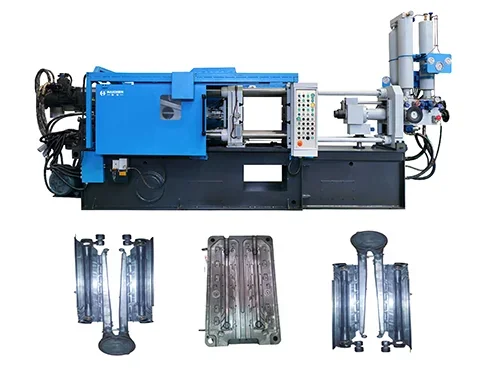

Our mold engineers will design the mold according to the drawings, including the gating system design, mold opening and closing position, slider design, and the number of cavities.

Our expertise in die casting allows us to provide high-quality, precision zinc and aluminum die casting parts that meet the specific requirements for your project.

Weight Difference between Cast Aluminium and Cast Iron

Cast aluminum is much lighter than cast iron.

Cast aluminum has a density of about 2.7 g/cm³, while cast iron has a density of about 7.8 g/cm³.

Which gives cast aluminum an advantage in applications that require weight savings, such as automotive parts and consumer electronics.

Thermal Conductivity and Heat Retention

Cast aluminum has three times the thermal conductivity of cast iron.

Which means that cast aluminum is able to transfer heat more quickly, while cast iron has better heat retention.

As a result, cast aluminum is suitable for applications that require rapid heating or cooling.

While cast iron is more suitable for applications that require uniform heating over long periods of time.

Corrosion Resistance Difference between Cast Aluminium and Cast Iron

Cast aluminum has higher corrosion resistance because a dense oxide film forms on the surface of the aluminum, effectively preventing further corrosion.

In contrast, cast iron is prone to rust and requires an additional protective coating to prevent corrosion.

Cast aluminum generally offers superior corrosion resistance to cast iron, forming a protective aluminum oxide layer that self-heals and prevents further degradation in various environments.

In contrast, cast iron is prone to rusting and corrosion from moisture and humidity.

Requiring regular maintenance or protective coatings to prevent it from failing in outdoor or wet conditions.

Differences in mechanical properties strength

Cast iron is generally stronger than cast aluminum, especially higher tensile strength and compressive strength.

The strength of cast iron makes it ideal for manufacturing components that require high load capacity, such as engine crankshafts, gears, etc.

Toughness Difference between Cast Aluminium and Cast Iron

Cast aluminum is tougher than cast iron and is less prone to breakage, but its tensile strength is lower.

Cast iron is significantly tougher than cast aluminum.

Especially when it comes to handling heavy loads, high stress, and impact resistance, due to its greater strength and density.

While cast aluminum is lightweight and offers good corrosion resistance, it is more ductile and less prone to cracking,

But it is also weaker, more brittle under impact, and less suitable for high-stress or high-temperature applications.

Abrasion resistance Difference between Cast Aluminium and Cast Iron

Cast iron is more abrasion resistant than cast aluminum, making it suitable for surfaces that need to withstand wear and tear for a long time.

Cast iron exhibits significantly superior abrasion resistance compared to cast aluminum.

Due to its harder matrix, making it the preferred material for heavy-duty, abrasive applications like mining and agricultural equipment, where wear is a primary concern.

While cast aluminum is lighter and more corrosion-resistant, cast iron’s inherent hardness and ability to incorporate wear-resistant elements like chromium provide a much higher tolerance for grinding and abrasion.

Differences in processing performance

Cast aluminum has better processing performance than cast iron.

Aluminum’s soft properties make it easier to cut, cast, and machine, while also achieving greater dimensional accuracy and surface finish.

However, due to the large coefficient of thermal expansion of aluminum.

Special attention needs to be paid to tolerance control during machining.

Cost Difference From a cost perspective, cast aluminum is generally more expensive than cast iron.

Despite the higher price of aluminum, its lightweight properties.

As well as processing efficiency, can reduce the overall cost of some applications.

Differences in application areas Cast aluminum

Due to its light weight, high strength and good corrosion resistance.

It is widely used in the automotive industry (e.g. engine cylinder heads), consumer electronics (e.g. laptop cases) and architectural decoration.

Due to its high strength, wear resistance and good casting properties.

It is commonly used in the manufacture of mechanical parts (e.g., gears, bearings), building structures (e.g., bridges), and kitchen utensils (e.g., pots).

Material composition and microstructure differences

Cast iron is an iron-carbon alloy whose main components are iron and carbon, and may also contain elements such as silicon, manganese, and sulfur.

The carbon in cast iron is in the form of graphite, and this graphitized structure gives cast iron good wear resistance.

The presence of graphite reduces the direct contact between the metal matrix and the abrasive, thereby reducing the wear rate.

In contrast, cast aluminum has a higher hardness, but it lacks a similar anti-friction mechanism in its microstructure, so it is inferior to cast iron in terms of wear resistance.

Differences in Hardfacing Ability

Cast iron has a case-hardening ability that can produce a hard wear-resistant surface layer and a soft plastic core through heat treatments such as quenching and tempering.

This case-hardening capability allows cast iron to maintain a high surface hardness when subjected to wear, resulting in improved wear resistance.

Cast aluminum, on the other hand, lacks similar hardfacing capabilities, has poor wear resistance, and is prone to wear and tear during use.

Differences in mechanical properties

Cast iron has higher tensile strength, flexural strength, and yield strength than cast aluminum.

Which means that cast iron exhibits higher strength and toughness when subjected to heavy loads, which reduces wear due to fatigue and fracture.

In addition, cast iron also has a higher damping capacity than cast aluminum, which helps to reduce damage to the material from vibration and shock.

Differences in heat treatment effect

After quenching and tempering treatment, the hardness and wear resistance of cast iron are significantly improved.

For example, WC-Co-Cr coated cast iron treated with thermal spray technology performs well in terms of wear resistance.

Which is further evidence that cast iron can significantly improve its wear resistance when properly treated.

In contrast, cast aluminum is difficult to achieve similar wear resistance even after surface treatment.

Cast aluminium and cast iron application examples

In practical applications, cast iron is widely used in components that require high wear resistance.

Such as engine blocks, transmission gears, etc.

These components are subject to high loads and wear over long periods of use, and the excellent wear resistance of cast iron makes them ideal for these applications.

While cast aluminium can be a substitute for cast iron in some cases, it is still a better choice for applications that require high wear resistance.

Which One Should You Go for?

Haichen is an experienced manufacturer of pressurizing machines and molds.

Our advanced technology and diverse processing methods enable us to produce high-quality pressurizing molds, providing you with the production of precise pressurized parts.

Haichen has designed various aluminum die-casting production lines for customers in different industries.

For instance, there are aluminium road studs, aluminium radiators, aluminium pots.

You can see that the range of these products is quite wide. But for die-casting, there is nothing impossible.

So, if you are in the medical, automotive, aerospace, and marine industries and are looking for machinery, reach out to us, and we will sort you out!

Didn’t find the answers you were looking for?

Contact us now for a free consultation.