Cast aluminum Advantages vs. Other Materials: Cast aluminum, in comparison to steel, or iron, is much lighter in weight, and it is also resistant to corrosion. In addition, it possesses a favorable ratio of strength to weight, as well as a high level of thermal and electrical conductivity.

In this regard, choosing a material for a given part is critical for obtaining the optimum performance and longevity of the part made in the casting processes.

Cast aluminum’s suitability in materials selection may be as a result of its favorable characteristics.

In this article, we discuss the key benefits of cast aluminum in comparison with other casting materials.

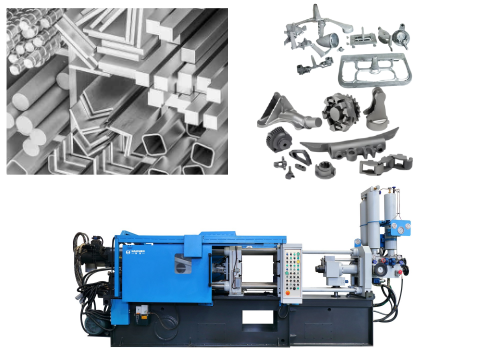

Major Benefits of Aluminum Alloy Die Casting

- Lightweight and High Specific Strength

- Excellent Thermal and Electromagnetic Properties

- Corrosion Resistance and Surface Treatment Flexibility

- Production Efficiency and Economy

- Complex Structure Forming Capabilities

Lightweight and High Specific Strength

- The die-casting process allows for a density of only 2.7 g/cm³ which is approximately one-third that of steel and allows for thin-wall designs of 0.5 mm. This significantly reduces the weight of components.

- The strength-to-density ratio for die-cast aluminum alloys is 300-400 MPa which is a tensile strength that helps achieve weight and load-bearing requirements for the automotive and aerospace industries.

Excellent Thermal and Electromagnetic Properties

- Thermal conductivity of aluminum with 96-140 W/(m·K) is over three times that of steel, making it a better choice for electronic device radiators and engine components.

- Aluminum alloy can RF shield and EMI shield making it possible to protect precision electronic equipment from outside interferences.

Corrosion Resistance and Surface Treatment Flexibility

- Aluminum alloy’s natural surface oxide film aids as a basic protection and further protection from anodizing and electrophoretic coating enhances the corrosion resistance.

- As for the exterior components, the reduced costs for post-processing is due to the high surface finish of Ra 1.6-3.2μm.

Production Efficiency and Economy

- In cold-chamber die-casting, the molds are filled at a rate of 16-80 m/s, with a 0.01-0.2 second filling time, to maintain high pressures and speeds. Cold-chamber die-casting machines can achieve a production rate of 50-90 pieces per hour, while hot-chamber machines are capable of 400-900 pieces.

- Molds can now achieve lifespans of several million pieces which is ideal for mass production. The recovery rates of aluminum alloys is above 95% which significantly lowers the costs of raw materials.

Complex Structure Forming Capabilities

- Fostering Able-Destructuring Systems In Insert Thin, One Piece, and Deep, One- Piece Forming Reduces the steps in assembly for, transmission housings, and midframes of mobile phones by integrating as many steps as possible.

Cast Aluminum Grades

- A356

- A380

- A360

- A206

A356

A356 is a widely used aluminum alloy known for its excellent mechanical properties and corrosion resistance. It is commonly used in the automotive industry for components such as engine blocks, transmission housings, and wheels. A356 offers high strength, good ductility, and excellent casting characteristics, making it suitable for a wide range of applications.

A380

A380 is another popular aluminum alloy used in die – casting. It is known for its superior flow properties, which allow for the production of intricate parts with thin walls and complex geometries. A380 is often used in the electronics and consumer goods industries for components such as housings, enclosures, and decorative parts. Its excellent dimensional stability and surface finish make it ideal for applications where appearance and precision are critical.

A360

A360 is a high – strength aluminum alloy that offers excellent corrosion resistance and good machinability. It is commonly used in the aerospace industry for structural components and in the automotive industry for high – performance parts. A360’s high strength – to – weight ratio and ability to withstand high – stress environments make it a preferred choice for applications requiring both strength and durability.

A206

A206 is a heat – treatable aluminum alloy known for its high strength and excellent casting properties. It is often used in applications requiring high – strength components, such as aircraft parts and automotive engine components. A206 offers good ductility and resistance to fatigue, making it suitable for parts that undergo repeated stress cycles.

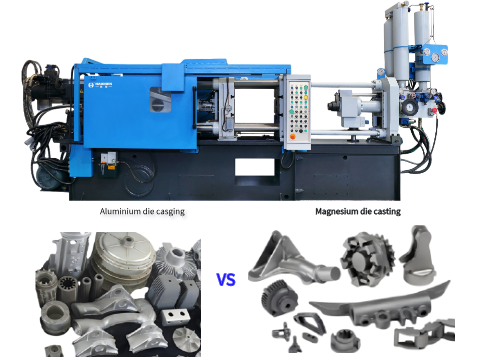

Cast aluminum Advantages vs. Other Materials

- Weight

- Strength

- Corrosion Resistance

- Thermal Conductivity

- Machinability

- Cost

Weight

Cast Aluminum

Cast aluminum is particularly well known for being lightweight when compared to other materials. Because of this, it is useful in parts which require strength- weight ratio, such as in the automotive or aerospace industries.

Other Materials

- Steel: It is significantly heavier than aluminum, which could pose as a disadvantage in applications needing lighter components.

- Zinc: Although lighter than steel, zinc is still heavier than aluminum and may not possess the same strength- to- weight ratio.

Strength

Cast Aluminum

Similarly to other materials, cast aluminum can also withstand high-stress environments and perform well in high durability applications. Unlike other materials, this one is slightly on the lighter side. This attribute combined with the ability to alloy aluminum with other metals enhances performance.

Other Materials

- Steel: It offers a high strength to weight ratio, so it can be used for applications needing extreme durability. But in other applications it will pose as a limiting factor due to its weight.

- Zinc: Provides good strength but is not as durable, especially in high- stress applications when compared to aluminum.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, which provides excellent corrosion resistance. This makes it suitable for outdoor and marine applications where exposure to the elements is common.

Other Materials

- Steel: Prone to rust and corrosion, especially in wet or salty environments. Requires additional coatings or treatments to enhance corrosion resistance.

- Zinc: Also forms a protective oxide layer but is less resistant to corrosion than aluminum, particularly in harsh environments.

Thermal Conductivity

Cast Aluminum

Aluminum has excellent thermal conductivity, making it ideal for applications where heat dissipation is critical. This property is particularly useful in the automotive and electronics industries, where components need to manage heat efficiently.

Other Materials

- Steel: Has lower thermal conductivity compared to aluminum, making it less suitable for applications requiring efficient heat transfer.

- Zinc: Also has lower thermal conductivity, which can limit its use in applications where thermal management is crucial.

Machinability

Cast Aluminum

Aluminum is relatively easy to machine which helps to lower manufacturign cost and increase efficiency. Parts can also be made to be very detailed and complex because of aluminum’s ease of machining.

Other Materials

- Steel: more often than not, aluminum is a more cost-effective spending option. However, the ease of machining aluminum comes with its challenges, and its hardness can make parts more expensive and time-consuming to manufacture.

- Zinc: Although easier to machine than steel, it is still not as efficient to machine as aluminum, which may affect efficiency in production.

Cost

Cast Aluminum

Aluminum is known to be cost-effective compared to other metals. Also, its strength and weight ratio remains an advantage, making it a common choice for numerous applications.

Other Materials

- Steel:Spending more than valuing cheaper alternatives comes with a price, and that also is the case with steel, where the price for aluminum is more than steel, and so is its machining price.

- Zinc: Although cheaper than steel, it is not as cost-effective as aluminum and comes with lower performance value.

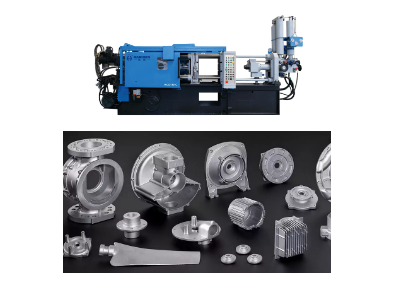

HAICHEN Aluminum Die Casting Solutions

- Aluminum Road Studs

- Aluminum Radiators

- Aluminum Pots and Pans

Aluminum Road Studs

HAICHEN specializes in providing die – casting and molding solutions for aluminum road studs of different sizes. Road studs are facilities used for road and traffic signs, primarily to mark the center line, lane demarcation line, and edge line of the road to guide vehicles and pedestrians in the right direction。

Aluminum Radiators

HAICHEN also offers a 300 – ton automatic aluminum radiator cold – chamber die – casting machine. This machine is designed for high – precision casting of aluminum radiators, ensuring high – quality and durable components for automotive and other applications。

Aluminum Pots and Pans

HAICHEN’s die – casting machines are used to produce aluminum pots and pans. The production process involves melting aluminum alloys and using a cold – chamber die – casting machine to press the molten alloy into specially designed molds. The resulting products are then cooled, extracted, and post – processed to ensure high – quality and market – ready products。

The efficacy with which your casting needs are fulfilled hinges on the material you choose to go with. One of the best options in the market is cast aluminum as it is lightweight, offers strength, has corrosion resistance, serves as a good thermal conductor, is easy to machine, and cost-effective.