The matching of casting processes with alloys is a complex task that requires balancing material properties, process requirements, economic factors, and application scenarios.

Alloy casting is the process of melting multiple metals (and occasionally non-metallic materials) into a mould. Upon cooling and solidification, the alloy casting assumes the shape of the mould used, producing components with appropriate properties.

Casting is a complex process that requires a comprehensive consideration of many factors to achieve the optimal part. Among these factors, how the material selection and the part application affect the quality of the final casting

Our experience in alloy die casting combined with case studies

- Casting Process Types and Compatible Alloys

- Key Factors for Alloy Selection

- Case Studies

- Tools and Resources

Casting Process Types and Compatible Alloys

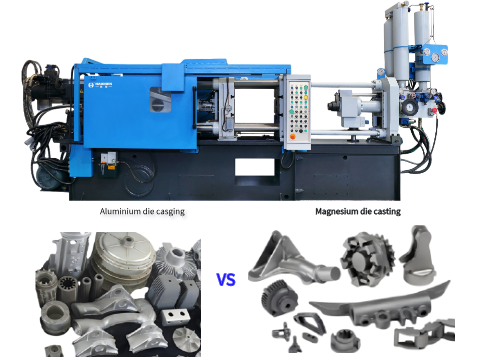

- Ideal for high-volume production with high precision and repeatability.

- Common alloys: Aluminum alloys (lightweight, corrosion-resistant for automotive parts), magnesium alloys (require rapid mold filling to avoid defects), zinc alloys, and copper alloys.

- Sand Casting

- Suitable for large/complex shapes (e.g., segmented bronze statues requiring multi-pour casting).

- Typical alloys: Brass (Cu-Zn) and bronze (Cu-Sn).

- Permanent Mold Casting

- Used for medium-volume production with smooth surface finishes.

- Examples: Al-Si-Mg alloys (e.g., IS AC-AlSi7Mg-K-T6) requiring heat treatment (solution treatment + artificial aging).

- Investment Casting

- Precision-focused for small components, often applied to high-temperature alloys in aerospace.

Key Factors for Alloy Selection

- Material Performance Requirements

- Corrosion Resistance: Aluminum/zinc alloys for moderate environments; stainless steel for extreme conditions.

- Strength & Lightweight: Al-Mg alloys enhanced with Zn/Cu; low-alloy steels for improved hardenability.

- Temperature Resistance: High-alloy steels (e.g., heat-resistant steels) outperform aluminum in high-temperature settings.

- Process Compatibility

- Magnesium alloys require optimized mold design due to rapid solidification.

- Die casting demands high fluidity (e.g., Zn/Al alloys for intricate molds).

- Cost and Production Scale

- Die casting: High mold cost (5k–5k–500k) justified by large batches.

- Sand casting: Low mold cost but lower precision, ideal for small batches or oversized parts.

Case Studies

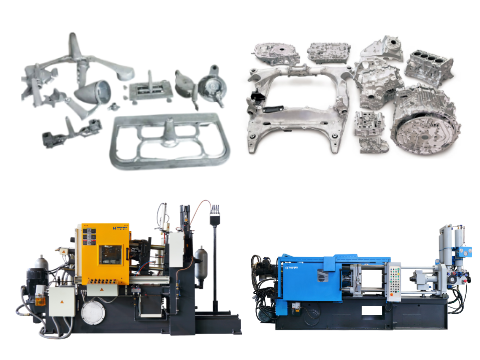

- Al-Mg Alloy Casting: Optimized with Si/Cu additions; produced via die/permanent mold casting for precision parts.

- Bronze Casting: Traditional segmented casting (e.g., Japan’s Kamakura Great Buddha) combines historical techniques with modern alloy technology.

- High-Alloy Steel Casting: Critical for aerospace, requiring controlled solidification to minimize segregation.

Tools and Resources

- AFS Alloy Database: Provides alloy properties and process recommendations for material-process pairing.

- MES Selection Guides: Advise selecting processes based on production volume first, then filtering alloys by performance, cost, and supplier capabilities.

Matching casting processes with alloys involves balancing performance, process feasibility, and economics:

- Die casting suits high-volume aluminum parts; sand casting excels for complex bronze components.

- High-alloy steels demand specialized process control (e.g., solidification management).

- Use databases and selection tools to optimize choices for specific applications.

Alloy characteristics matching by die casting process

Characteristics of Alloys Suitable for Die Casting

Die casting requires strict compatibility with alloy properties, balancing process performance and functional requirements.

Let’s show key alloy characteristics and material selection principles:

- Core Requirements for Die-Casting Alloys

- Common Die-Casting Alloys

- Emerging Trends

- Selection Guidelines

Core Requirements for Die-Casting Alloys

- Narrow Solidification Temperature Range

- Avoids dendritic growth during solidification, reducing flow resistance and defects like shrinkage porosity.

- Example: Al-Si alloys (e.g., A380.0) solidify with minimal temperature variation, ideal for intricate parts.

- High-Temperature Strength and Ductility

- Maintains structural integrity under thermal stress to prevent hot tearing.

- Example: Al-Mg alloys offer good room-temperature strength but poor castability.

- Low Shrinkage Rate

- Minimizes dimensional changes during cooling. Zinc alloys (e.g., Zamak 3) excel here, ensuring high precision.

- Excellent Fluidity

- Critical for filling thin-walled molds rapidly. High-Si aluminum alloys leverage silicon’s latent heat for superior flow.

- Low Melting Point & Thermal Fatigue Resistance

- Low melting points (e.g., Zn alloys at ~400°C) extend mold life to over 1 million cycles.

Common Die-Casting Alloys

| Alloy Type | Pros | Cons | Applications |

|---|---|---|---|

| Aluminum | High strength-to-weight ratio (e.g., ADC12), corrosion resistance | Prone to mold sticking, high shrinkage | Automotive parts (engine blocks, housings) |

| Zinc | Low melting point, exceptional surface finish | Susceptible to aging, requires high-purity feedstock | Electronics, decorative components |

| Magnesium | Lightest structural metal (e.g., AZ91D), vibration damping | Oxidation risk, poor corrosion resistance | 3C product casings, aerospace |

| Copper | Superior conductivity/wear resistance (e.g., ZCuZn40Pb2) | High melting point (>900°C), costly molds | Electrical contacts, bearings |

Emerging Trends

- Heat-Treatment-Free Alloys

- Al-Si-Cu-RE alloys (e.g., SILAFONT-36) achieve T6-level strength without post-casting heat treatment, reducing energy use in structural parts.

- High-Strength Alloys

- Vacuum die-casting-compatible alloys (e.g., C611) combine thermal stability with mechanical toughness for automotive safety components.

Selection Guidelines

- Functional Needs: Prioritize strength, corrosion resistance, or conductivity.

- Process Constraints: Match alloy flowability to part geometry (e.g., thin walls demand high-Si Al alloys).

- Cost-Efficiency: Balance material cost (e.g., Zn vs. Mg) with mold longevity and cycle time.

Example: B390.0 aluminum is preferred for engine blocks due to wear resistance, while Mg alloys dominate lightweight electronics.

By aligning alloy properties with die-casting parameters and end-use demands, manufacturers optimize performance and cost-effectiveness.

Feel free to contact HAICHEN to learn more about die casting equipment and alloy technology information.