A release agent mixer characteristics for die casting machines is designed to evenly blend and apply release agents, ensuring smooth part ejection, preventing mold sticking, and maintaining high production efficiency and part quality.

A release agent mixer for a die-casting machine is a specialized device used to prepare and mix the release agent with water (or another carrier) in precise proportions.

The release agent is a chemical compound sprayed onto die surfaces during the casting process to prevent molten metal from sticking to the molds, facilitating easy removal of cast parts and extending the die’s lifespan.

In this article, we will explore the key characteristics of release agent mixers specifically designed for die casting machines.

Release agent mixer characteristics

- Mixing Efficiency of release agent mixer characteristics

- Material Compatibility

- Capacity and Scalability

- Ease of Operation

- Precision and Consistency

- Durability and Maintenance

- Safety Features of release agent mixer characteristics

- Integration with Die Casting Machine

- Environmental Considerations

- Key Benefits of release agent mixer for die casting machine

Mixing Efficiency of release agent mixer characteristics

- Uniformity: Ensures the release agent and water are mixed homogeneously for consistent application.

- Adjustable Ratios: Supports precise mixing ratios to meet specific requirements, typically ranging from 1:100 to 1:50 depending on the release agent used.

Material Compatibility

- Corrosion Resistance: Constructed from stainless steel or similar materials to resist corrosion from water and chemicals in the release agent.

- Non-reactivity: The mixer materials must not chemically interact with the release agent.

Capacity and Scalability

- Designed to handle volumes that match the operational needs of the die-casting machine.

Ease of Operation

- Automatic or Manual Control: Options for fully automated systems or manually adjustable mixers.

- User-friendly Interface: Simple control panels with settings for ratio adjustment and monitoring.

Precision and Consistency

- Equipped with flow meters or sensors to maintain consistent output.

- High precision in delivering the correct concentration for optimal release performance and cost efficiency.

Durability and Maintenance

- Robust Design: Built to withstand the harsh industrial environment.

- Easy Maintenance: Components such as nozzles and mixing chambers are designed for quick cleaning or replacement.

Safety Features of release agent mixer characteristics

- Overpressure protection to prevent damage to the system.

- Leak detection systems to ensure safe operation.

Integration with Die Casting Machine

- Synchronization with the die-casting process to apply the release agent at the right time.

- Compatibility with the machine’s spray systems for seamless operation.

Environmental Considerations

- Reduces waste by accurately mixing and dispensing the release agent.

- May include recycling systems for excess material to minimize environmental impact.

Key Benefits of release agent mixer for die casting machine

- Prolongs die life by reducing wear and sticking.

- Enhances surface quality of cast products.

- Optimizes the use of release agents, reducing operational costs.

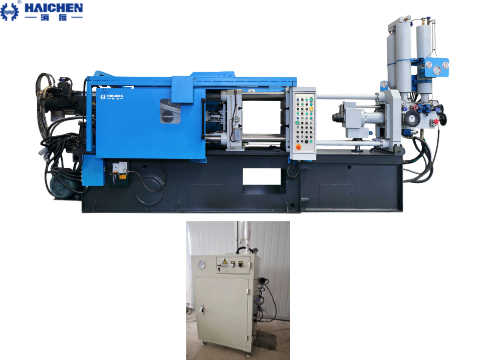

Haichen Release agent mixer characteristics for die casting machine

Haichen is a die casting machine factory located in Ningbo, China, mainly supplying cold chamber die casting machine and hot chamber die casting machine. Besides machines, we also supply die casting auxiliary equipments, including release agent mixer, ladles and extractors and so on.

Here are the Haichen Release agent mixer characteristics:

Automatic Mixing and Proportioning: It ensures accurate dilution of the release agent with water, providing a consistent mix ratio. This automation helps minimize waste and improve the release agent’s effectiveness.

Liquid Level Monitoring: Equipped with sensors to monitor liquid levels, it automatically refills or alerts operators when the concentrate or diluent reaches a critical level.

Pressure Control: The system includes pressure monitoring and maintenance features, ensuring stable output pressure for consistent application.

Cost-Effectiveness and Return on Investment Analysis

For manufacturers considering the purchase of die-casting equipment, evaluating the cost-effectiveness of a release agent mixer is a key part of the selection decision. A well-designed mixer can deliver a significant return on investment by improving process stability and resource efficiency. This section analyzes the economic characteristics of a release agent mixer from a total cost of ownership perspective.

- Total Cost of Ownership Analysis

- Operational Cost Savings

- Return on Investment and Production Benefit Improvement

Total Cost of Ownership Analysis

Evaluating the cost of a release agent mixer should not only consider the initial purchase price. The total cost of ownership includes the equipment purchase cost, installation and commissioning fees, daily operational costs for release agent concentrate, water, electricity, regular maintenance costs, and potential losses from unexpected breakdowns. A mixer with high-precision ratio control and excellent durability may have a slightly higher initial investment. However, it can achieve a lower overall cost in the long run by significantly reducing material waste and lowering failure rates.

Operational Cost Savings

An efficient mixer directly impacts variable production costs. Core savings come from two areas: First, precise automatic proportioning avoids overuse of the release agent caused by uneven manual mixing or incorrect ratios, potentially saving 10%-25% of concentrate consumption. Second, consistent mixture quality ensures stable spray results. This reduces casting defects due to poor release, mold cleaning frequency, and downtime, indirectly saving labor and energy costs.

Return on Investment and Production Benefit Improvement

Viewing the mixer as a process investment, its return is realized through improved production benefits. For instance, HAICHEN’s automatic mixing and proportioning system ensures consistent solution concentration for every batch. This directly improves mold release success rates and casting surface quality, reducing downstream processing costs. For a production line with an annual output exceeding 200,000 castings, a reliable mixing system typically pays for itself within 12-18 months through saved release agent costs and reduced scrap. It continues to deliver net benefits thereafter, ensuring production continuity and high cycle rates.

Selection and Application Recommendations

| Scenario | Recommended Capacity | Key Configuration | Notes |

| Small Workshop (Annual Production 50,000 pieces) | 100L-200L | Basic Heating, Automatic Mixing, Filtration | Affordable, Meets Daily Needs |

| Medium Workshop (Annual Production 200,000 pieces) | 300L-500L | Vacuum Degassing, PLC Touchscreen, Recovery System | Improves Stability, Reduces Material Waste |

| Large High-End Workshop (Annual Production >500,000 pieces) | 500L-1000L | Multi-stage Temperature Control, Dual Filtration, Online Monitoring (Concentration, Viscosity) | Supports Multi-Product Switching, Meets High-Capacity Needs |

The release agent mixer is an essential component in the die casting process. Its characteristics, such as uniform mixing, precise control, consistency and reliability, compatibility with die casting machines, easy maintenance and cleaning, and safety features, all contribute to the efficient and high – quality production of die – cast parts.

When selecting a release agent mixer, it’s essential to consider your specific die-casting application requirements, the type of release agent used, and the scale of production.

By choosing a high – quality release agent mixer, manufacturers can optimize their die casting operations and produce high – quality parts that meet the demands of the market.