The best maintenance for a die casting machine involves:

- Maintenance Tools

- Mold maintenance

- Use lubricants to maintain die casting machines

- Maintenance for die casting machine filters

- System maintenance

The die-casting machine has strict requirements for the safe operation of the operator; the correct maintenance of the machine can not only protect the safety of personnel and equipment, but also help improve economic benefits.

In order to ensure the normal operation of the die-casting machine, scientific maintenance should be carried out while using it correctly.

Therefore, it is necessary to work out the operating rules and maintenance management system of the machine in accordance with the requirements of the manual and related regulations, especially the safety rules.

It’s like in Haichen Machinery,special personnel are responsible for the implementation and implementation, and illegal operations are strictly prohibited.

Maintenance Tools

You need the right tools to keep your die casting equipment in top shape. Basic hand tools like wrenches, screwdrivers, and pliers help you adjust and repair parts quickly.

Torque wrenches let you tighten bolts to the correct level, which protects your die casting mold and prevents leaks. Use calipers and micrometers to check the dimensions of your die mold and finished parts.

Inspection mirrors and flashlights help you see inside tight spaces. You also need a multimeter to test electrical systems and a pressure gauge for the hydraulic system.

These tools help you spot problems early and keep your die casting process running smoothly.

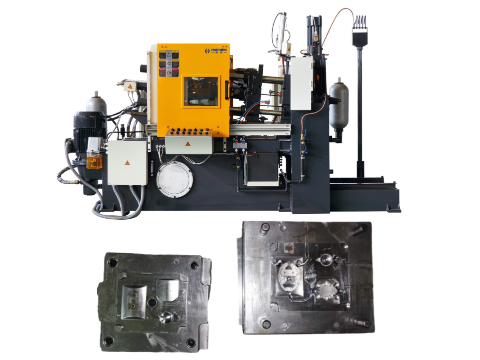

Mold maintenance

Die casting die has been in high pressure, high speed, high temperature continuous production, the use conditions are relatively bad. In the process of using, the mold will produce damage or hidden trouble.

Therefore, it is very important to strengthen the maintenance of the mold, regularly maintain the mold, replace the damaged parts, replace the vulnerable parts, clean the slide way, ejector pin hole, etc.

It is very important to ensure the reliability of the mold in the die-casting production, and also can extend the service life of the mold.

At the same time, because the die-casting die is constantly impacted, expanding and shrinking continuously, new internal stress will be produced.

If it is not eliminated in time, the die surface is easy to crack or crack. Therefore, it is also an important means to prolong the life of the die by means of stress relief tempering regularly.

Generally, the first tempering should be carried out after 3000-5000 mold times after the mold is put into use.

In the future, according to the use of the situation, generally every 10000 mold production, the mold cavity to carry out stress tempering, which can greatly extend the service life of the mold.

Use lubricants to maintain die casting machines

Lubrication is a key part of die casting machine maintenance.

Use the right lubricants for each part of your die casting machine:

- Water-based lubricants provide both lubrication and cooling, making them ideal for high-pressure die casting and aluminum die casting.

- Oil-based lubricants give a high-quality finish but do not cool as efficiently.

- Some lubricants act as release agents, while others insulate the die.

- Water-soluble non-graphite lubricants reduce die wear and prevent sticking without causing corrosion.

- Solid punch lubricants improve lubrication during the die casting process.

- You should lubricate your die casting machine regularly. Follow the manufacturer’s guidelines for each part. Use lubrication charts to identify the correct lubricant and frequency.

- Proper lubrication extends the life of your die casting mold and die mold, ensuring smooth operation and reducing downtime.

Every component of a die casting machine requires the right lubricant and lubrication frequency. Proper lubrication can extend the lifespan of die casting molds, ensuring smooth machine operation and reducing downtime. If you are unsure, you can ask Haichen‘s engineers for the correct lubrication method.

Maintenance for die casting machine filters

When the equipment has a filter indicator, always check the filter’s indicator. When the indicator pointer is in the green area, it is normal.

In the yellow area, it is slightly blocked, and in the red area, it is severely blocked. When the pointer enters the yellow area, the filter element must be cleaned.

The filter screen filters the oil internally to ensure the oil’s quality further. Therefore, it is necessary to regularly check whether the filter screen has too many impurities or blockages.

If there is any problem, it should be cleaned or replaced.

Die casting machine system maintenance

- Lubrication Maintenance

- Hydraulic System Maintenance

- Electrical System Maintenance

- Cooling System Maintenance

- Mould Maintenance

Lubrication Maintenance

Regularly inspect and maintain sliding parts and lubricating oil circuits to ensure the normal operation of the lubrication system.

The lubricating oil needs to be changed regularly, e.g. every 500 hours and every 2000 hours.

Hydraulic System Maintenance

Check the pressure and flow of the hydraulic system to ensure that it is operating within the normal range.

Regularly check the quality of the hydraulic oil and the replacement cycle, and replenish or replace the hydraulic oil in time.

Electrical System Maintenance

Check whether the connections of the electrical wiring are loose or damaged to ensure the normal operation of the electrical components.

Regularly check the safety of electrical equipment to avoid production interruptions due to electrical problems.

Cooling System Maintenance

Clean cooling pipes, replace coolant, and check for leaks regularly to ensure proper operation of the cooling system.

Mould Maintenance

Clean the mold surface regularly, remove metal chips and lubricant residues, and check the mold for wear.

The cleaning of the mold waterway is also an important part of ensuring the performance of the mold.

Importance of Regular Die Casting Machine Maintenance

- Enhanced Equipment Longevity

- Improved Production Efficiency

- Optimal Product Quality

Enhanced Equipment Longevity

Die casting machines are a significant investment for any manufacturing facility.

Regular maintenance, including cleaning, lubrication, and part replacements, helps prevent wear and tear, extending the overall lifespan of the machinery.

This not only protects your initial investment but also reduces the frequency of costly replacements.

Improved Production Efficiency

Well-maintained die casting machines operate more efficiently.

Routine inspections and servicing prevent unexpected breakdowns, minimizing downtime.

This reliability allows for consistent production schedules, ensuring that deadlines are met and customer expectations are exceeded.

Optimal Product Quality

The quality of the end product is directly influenced by the condition of the die casting machine.

Regular maintenance helps identify and rectify issues such as misalignment, wear on components, or casting defects.

By addressing these problems promptly, manufacturers can maintain consistent product quality and reduce the likelihood of defective items reaching customers.

Haichen‘s training

Haichen’s development and adherence to strict safety operating procedures is key to ensuring the safety of equipment and personnel.

This includes regular training of operators to ensure they understand the proper use of equipment and what to do in case of an emergency.