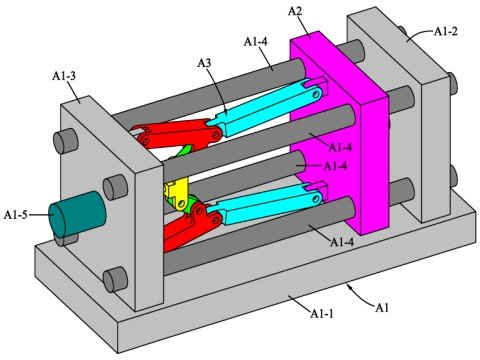

The clamping unit main components of die casting machine include clamping plates, tie bars, clamping cylinders, toggle mechanism,etc.

The clamping system is an essential part of a die casting machine as it secures the molds together during the injection sequence.

It keeps the molds closed during the high pressure stage of the process to protect against leakage of the molten metal and to ensure quality castings are produced.

Here, I will discuss the primary parts of the clamping unit and their roles.

clamping unit main components

- The Clamping Plates

- Tie Bars

- Clamping Cylinders

- Toggle Mechanism

- Ejector System

- Mold Alignment System

The Clamping Plates

As parts of the clamping unit, clamping plates perform the primary structural functions. And then they provide the rigidity and support needed to hold the mold halves and parts together. During the injection process, great forces are generated; thus, we design the clamping plates to withstand these forces and to keep the mold closed and aligned.

Tie Bars

Tie bars are used to connect the clamping plates and to provide the clamping unit with some rigidity. We use high strength steel to make these tie bars and design them to withstand the tensile forces that the clamping action will apply to them. The tie bars also provide the required rigidity to the clamping plates, thus preventing failure from the expanding parts. Because of this, the mold halves will not be misaligned.

Clamping Cylinders

Clamping cylinders are hydraulic or pneumatic actuators that provide the closing and holding force required to close the mold. As with clamping plates, clamping cylinders are connected to the plates and their operation is controlled by the machine’s hydraulic or pneumatic system. The clamping cylinders provide the required clamping force to hold the mold during injecting of the molten metal.

Toggle Mechanism

The toggle mechanism is used in a machine to increase the clamping force. It is formed by a set of levers and links which increase the power of the clamping action by transforming the linear motion of the clamping cylinders. With toggle mechanisms, it is possible to get a greater clamping force from a smaller cylinder which also decreases the size and cost of the clamping unit.

Ejector System

After the injection process, it is the ejector system that removes the cast part from the mold. It is composed of ejector pins or plates which are moved by hydraulic or pneumatic cylinders. And then the ejector system is designed to control the force used to remove the cast part in a manner that it does not damage the part.

Mold Alignment System

Precise alignment of the mold halves must be done before the clamping process starts, this is done by the mold alignment system. This system is made up of guide pins and bushings which fit into matching holes in the mold halves. The alignment system is responsible for accurate positioning of the mold halves together to eliminate the chances of faulty castings due to misalignment.

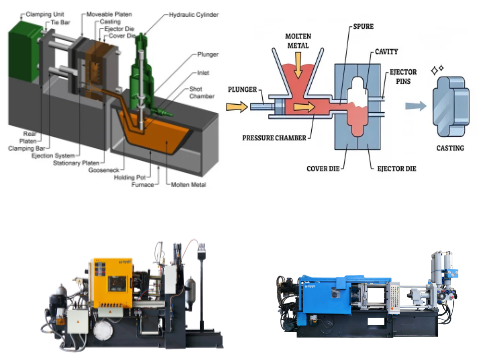

Differences in Clamping Units Between Hot Chamber and Cold Chamber Die Casting Machines

Although the clamping mechanisms of the two types of die casting machines are identical, process differences lead to the following characteristic differences:

| Parameters | Hot Chamber Die Casting Machine | Cold Chamber Die Casting Machine | Impact on Clamping Unit |

| Clamping Force Requirement | Lower (Zinc alloys have better fluidity) | Higher (Aluminum alloys require greater expansion resistance) | Cold Chamber Die Casting Machine Tie Rod Diameter Increased by 15% |

| Production Rate | 600 cycles/hour (High Cycle) | 200 cycles/hour | Hot Chamber Die Casting Machine Requires Enhanced Elbow Wear Resistance |

| Mold Temperature | 300°C (Zinc Alloy) | 700°C (Aluminum Alloy) | Cold Chamber Die Casting Machine Requires Forced Cooling Channels for Platens |

HAICHEN: Die Casting Machine Manufacturer

Among die casting machine manufacturers, HAICHEN is well-recognized for their commitment to product quality and performance. With HAICHEN, customers are assured of technologically advanced, rugged machines built to survive the harsh conditions of industrial environments.

With HAICHEN, customers are assured of technologically advanced, rugged machines built to survive the harsh conditions of industrial environments. We also provide hot and cold chamber die casting machines tailored to specific productivity requirements. Further, HAICHEN customers are offered complete after sales services comprising of prompt technical assistance, spare parts supply, and even customer training, all aimed at optimizing the customer’s return on investment.

In conclusion, to prevent downtime and ensure smooth operation of die casting processes, it is vital to understand the primary components of the clamping unit. By maintaining these components and ensuring proper operation, manufacturers are able to achieve consistent and efficient production of quality castings.