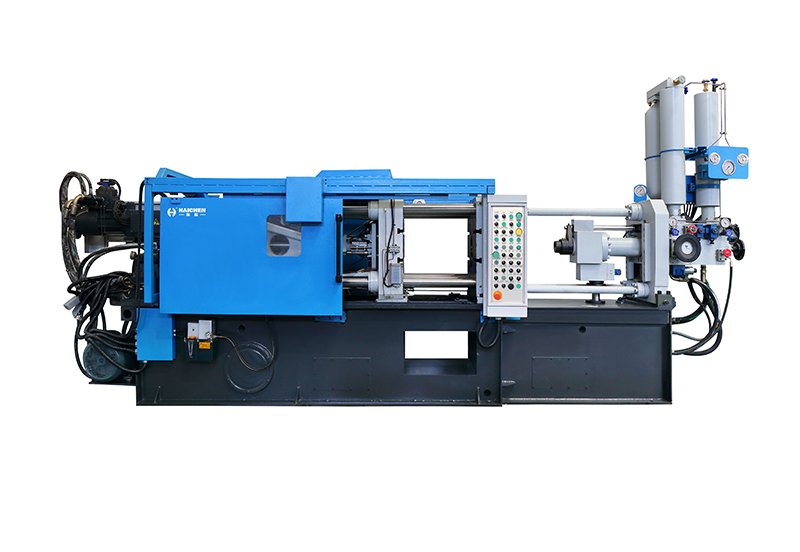

Haichen Cold chamber die casting machine

HCD-C series

The HCD-C cold chamber die casting machine offers locking forces from 350 to 20800 kN for producing aluminum and magnesium parts. Haichen cold chamber die casting machine with C and AL series.

The HCD-C cold chamber die casting machine offers locking forces from 350 to 20800 kN for producing aluminum and magnesium parts.

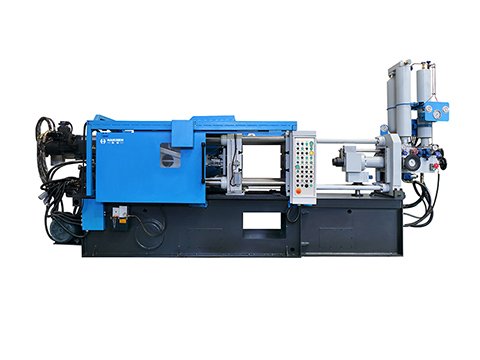

Small cold chamber die casting mahcine

A small cold chamber die casting machine is used for producing small and medium-sized castings, usually suitable for die casting of non-ferrous alloys such as aluminum and copper. This type of equipment is widely used in fields such as aviation, automotive, telecommunications instruments, and home hardware, especially when producing large quantities of complex castings with high-quality requirements.

The tonnage range of Haichen small cold chamber die-casting machine can vary from 30 tons to 140 tons according to different technical requirements. For example, the Haichen C series small and medium-sized cold chamber die-casting machine has a clamping force range of 30-150 tons and advanced injection, clamping, and control performance. The small aluminum precision cold chamber die-casting machine is an application of small equipment in precision casting. The small die casting machine price range of 10000 to 20000 US dollars.

There is also a certain demand and development potential for small cold chamber die-casting machines in the global market. According to relevant reports, the global market for small cold chamber die-casting machines is growing and is expected to continue expanding in the coming years. This growth reflects technological advancements and increased market demand, especially in the field of high-end die-casting technology.

Small cold chamber (AL) die casting applications

38 Ton small die casting machine

The HCD-38C (38 tons) ,380 kN horizontal cold chamber die-casting machine is the mini die casting machine manufacture by Haichen. The price of small die-casting machines generally ranges from tens of thousands to tens of thousands of yuan per unit

90 Ton die-casting machine

The HCD-90C(90 ton), 900kN small cold chamber die-casting machine applications: Household appliances and daily hardware.

140 Ton cold chamber machine

Die casting machines are used to produce automotive and motorcycle parts, communication products, aerospace, household appliances, building materials, and power tools.

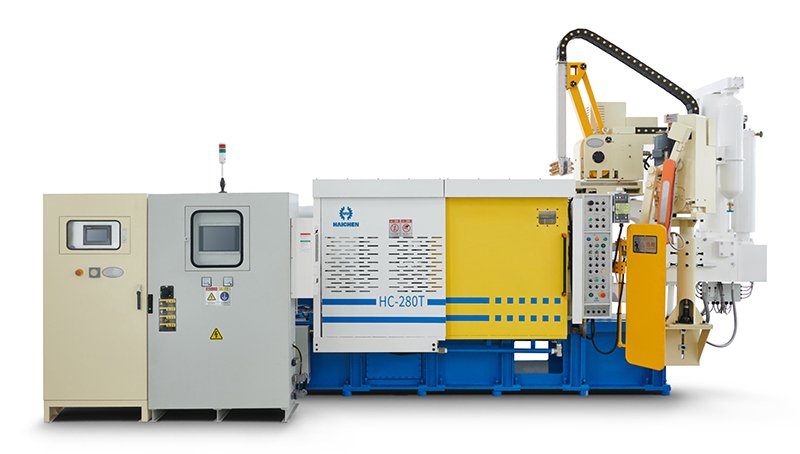

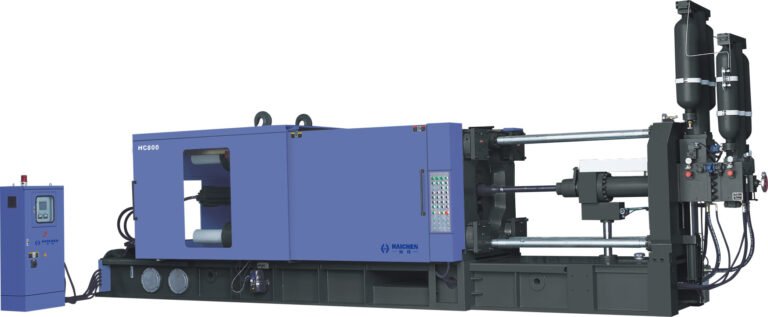

Medium size die casting machine with cold chamber

The clamping force range of medium-sized cold chamber die-casting machines is usually between 130 tons and 900 tons. The Haichen C series medium-sized cold chamber die-casting machine has a clamping force range from 130 tons to 900 tons, suitable for manufacturing non-ferrous metal die-casting products such as automotive and motorcycle parts, industrial parts, building materials parts, furniture supplies, etc.

In addition, the technical parameters and performance requirements of medium-sized cold chamber die-casting machines are also very important. For example, this series of die-casting machines has independent two speed and boost energy storage devices, which can automatically store energy and can be set and adjusted on the human-machine control interface. Its maximum air injection speed can reach over 8m/s, equipped with a fast locking mechanism, which increases the maximum speed by more than twice, shortens the cycle period, and improves production efficiency.

Medium size die casting applications with cold chamber

200 Ton cold chamber machine

200-ton Die casting machines can manufacture door handles, electrical boxes, LED lamp housings,heat sink, and many other products

300 Ton die-casting machine

The 300 ton die-casting machine is capable of processing aluminum alloy materials and is suitable for producing heat dissipation back covers for LED lights.

480 Ton cold chamber die-casting machine

big size die-casting machines (such as 480 ton die-casting machines) can theoretically be used to produce various metal parts, including small radiators and small aluminum alloy accessories.

580 Ton die-casting machine

500-ton Die casting machines applications: Radiator, Road lamp, aluminum Pot, Fly pan, Auto parts, …

680 Ton die-casting machine

600-ton Die casting machines applications: LED lamp housings, Auto parts, Washing machine motor rotor, soup pot, fly pan…

880 Ton cold chamber die casting machine

800-ton Die casting machines applications: LED lamp housings, Auto parts…

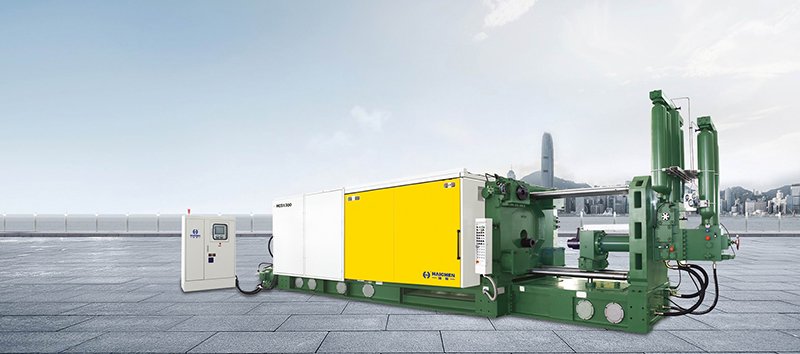

Large cold chamber die casting mahcine

The integrated molding technology for new energy vehicles uses large tonnage die-casting machines to shape multiple aluminum alloy components into a large structural component at once, thereby achieving the goals of lightweight body, improved production efficiency, and cost reduction.

The core of integrated die-casting technology lies in the use of large-scale cold chamber die-casting machines for production. It can achieve integrated die-casting molding of large structural components such as body and chassis, including new energy vehicles.

Tesla is a pioneer in this technology, and its Model Y model adopts integrated die-casting technology for the rear body, reducing the need for 700-800 welding points on the rear floor of the vehicle to 50 welding points, greatly improving the stability of the vehicle structure.

Large size die casting applications

1080 Ton cold chamber die-casting machine

1000-ton larger cold chamber die-casting machine machine can produce 2 cavities radiators, auto parts.

1380 Ton die casting machine

1300 ton cold chamber die-casting machine suit to produce: Refrigerator and washing machine accessories, auto parts…

1680 Ton die-casting machine

Used for producing engine parts, car seat frames, etc. Integrated die-casting of new energy vehicles

Advanced Cold Chamber die Casting Machine Manufacturers

Cold chamber die casting can provide high-pressure die casting, therefore it has advantages such as environmental protection, energy saving, high production efficiency, strong adaptability, high degree of automation, stable process, superior mechanical performance, safety and durability.

We provide high-quality cold chamber die-casting machines at affordable prices for Mexico, India, Pakistan, the Middle East, and China.

Quick view parameter of casting machine

Shot unit:

Closed-loop real-time control for injection unit, or servo valve control for injection.

Drive technology:

- Servo-drive

- Variable frequency motor

Clamping force:

350 – 20.800 kN

Clamp system:

350 – 20.800 kN

Tie bar distance:

270 x 270 mm to 1350 x 1350 mm

Shot volume (aluminum):

0.4 – 42 kg

Providing Cold Chamber Die Casting Machine at an affordable price

Haichen die-casting machine has a high cost-performance ratio and is directly sold by the manufacturer with transparent prices. Haichen is well-known in the die-casting machine industry for its automated die-casting production. With years of rich manufacturing experience, we have comprehensively developed various high-performance automatic die-casting technologies.

The Haichen C series high-efficiency and energy-saving aluminum alloy cold chamber die-casting machine has a price range between $15000 and $720000, still, its high-efficiency and energy-saving features can save energy costs in long-term use.

Directly purchasing from Haichen die casting machine manufacturers can reduce intermediate links and lower costs.

Highlight features of cold chamber casting machine

Injection ctonrol

注射伺服阀控制

This is one optional injection control, by servo valve.

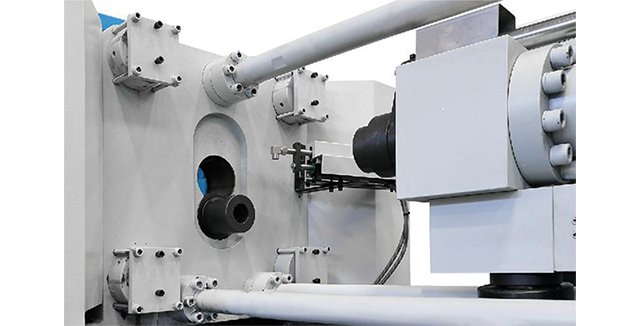

Injection frame- AL series

注射C型设计-AL系列

The “AL” Series cold chamber machine with C-type injection unit

Injection high-speed

注射快压增压

Up-to-date die casting machine technology, High-speed press-injection device. Boosting pressure by accumulatora.

Control system

电脑控制系统

Import high-class industrial controller-screen display by international famous brand.

Clamping unit

压铸锁模

Bending elbow tilting five fulcrum clamping machine

Platen high quality

高钢性球墨合金模板

High-rigidity ductile alloy platen

What is cold chamber die-casting machine

Cold chamber die-casting machine is a high-pressure die casting equipment that does not immerse the injection chamber and injection punch into the molten metal, but pours a certain amount of molten metal into the injection chamber and then performs injection. This type of equipment is typically used for processing non-ferrous metal materials such as aluminum alloys, magnesium alloys, and copper alloys.

Difference between hot chamber and cold chamber die casting

Hot chamber die-casting machine:

1. The chamber(gooseneck) is immersed in an alloy liquid that maintains a constant temperature. This design allows the molten metal to be directly injected into the mold under high pressure, simplifying the operation process.

2. Used for casting low melting point metals such as zinc, copper, and lead.

Cold chamber die-casting machine:

1. The chamber and furnace are separate, and the molten metal needs to be poured from the crucible into the injection chamber for injection.

2. Used for high melting point metals such as aluminum, magnesium, copper.