Cold chamber die casting machine manufacturers in China:

- Yizumi Holdings Co., Ltd.

- LK Group (GS)

- Haitian

- Sanji Foundry Equipment

The major manufacturers of cold chamber die-casting machines in China.

Such as LK Machinery Group, Yizumi, and Suzhou Sanji Foundry Equipment Co., LTD., enjoy a high market share and strong technical capabilities in the industry.

These enterprises have performed well in terms of customer reviews and industry reputation.

Especially being widely recognized for their product quality, technological innovation and after-sales service.

Yizumi Holdings Co., Ltd.

Yizumi is a well-known cold chamber die casting machine manufacturer.

And its HII series cold chamber die casting machine was developed in cooperation with the Chinese R&D team with higher injection accuracy and production efficiency.

In addition, Yizumi also cooperated with Sinyuan ZM to develop a large 3200-ton die-casting machine.

And signed a contract at the GIFA exhibition in Germany.

Marking the breakthrough of Chinese enterprises in the global large-scale die-casting machine market.

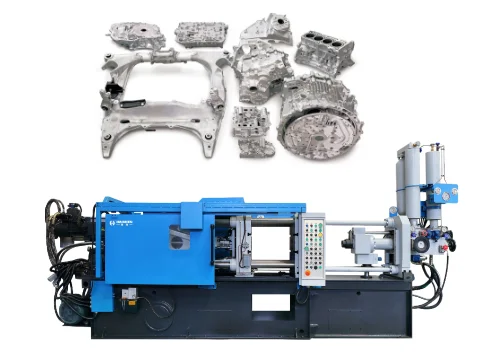

LK Group (GS)

LK Group is another important cold chamber die casting machine manufacturer in China.

And its products include LK 3rd generation 2000 ton cold chamber die casting machine.

LK 5 3200 ton cold chamber die casting machine, etc.

LK Group’s products are widely used in the casting of aluminum alloys, magnesium alloys and other materials.

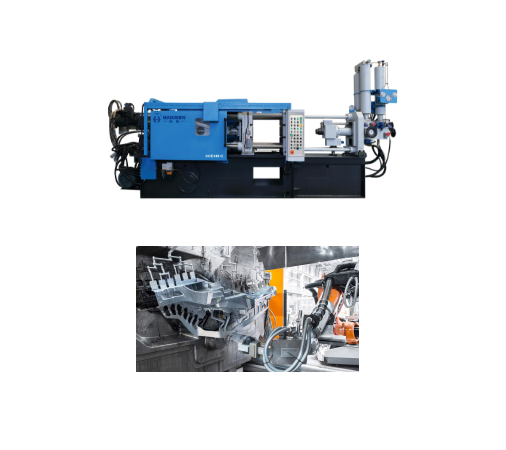

Ningbo Haitian Metal Forming Equipment Co., Ltd.

Haitian Die Casting was established in 1966 and has 50 years of manufacturing experience.

Its HDC series cold chamber die casting machine has a variety of models, ranging from 180T to 4000T.

And adopts advanced automatic production lines and servo systems to ensure the high precision and stability of the products.

Sanji Foundry Equipment

“Sanji began operations in 1996. Since then, this high-tech enterprise has specialized in R&D, production, and sales of: (1) squeeze-casting and die-casting machines; (2) precision castings; and (3) related automated equipment and intelligent production management software.

In over 20 years of development, Sanji has successfully provided the whole set solution of precision casting for hundreds of companies.

The company has many new products and technologies that have filled the technology gaps in China and reached the international advanced level.

What is cold chamber die casting machine?

Cold chamber die casting machine excels at manufacturing complex and large-sized components.

Unlike other die casting methods, it uses a separate furnace to melt metals with high melting points, such as aluminum.

This separation process can precisely control the metal during die-casting, thereby producing complex-shaped components with outstanding strength.

Application of cold chamber die casting machine

- Car & Motorcycle Parts

- Industrial parts

- Building material parts

- Furniture

- Consumer Electronics & Communication

- Other Industries

Car & Motorcycle Parts

Cold chamber die casting machines from Chinese manufacturers can be used to manufacture parts for cars and motorcycles.

For example, the IMPRESS series die casting machine is one of the main products of LK Group.

With clamping forces ranging from 130 tons to 900 tons, which can meet the production needs of high-precision and complex die castings.

Industrial parts

The manufacture of industrial parts is also an important application area for cold chamber die casting machines.

These parts usually require high strength and high precision.

And LK’s die casting machines are supported by advanced technology and equipment to efficiently produce high-quality industrial parts.

Building material parts

Such as door and window frames, building structural parts, etc.

These parts have high requirements for material properties.

And the equipment of Chinese manufacturers is able to provide stable production capacity and high-quality products.

Furniture

Particularly in the furniture manufacturing sector, Furnishings LK’s cold chamber die casting machines find extensive application for producing complex hardware components.

For example, components such as metal frames, connectors.

And other components in furniture can be produced efficiently by cold chamber die casting machines.

Consumer Electronics & Communication

Equipment Cold chamber die casting machines also have important applications in the field of consumer electronics and communication equipment.

For example, in the fields of smartphones, computers, and telecommunications infrastructure.

LK’s die-casting machines are capable of producing lightweight, high-strength metal parts.

Other Industries

Cold chamber die casting machines are also used in the production of other non-ferrous metal die castings such as escalator steps, industrial/road lamp housings, etc.

Haichen’s cold chamber die casting machine

- High precision and high quality

- Efficient production and automation

- Energy saving and environmental protection

- Technological Advantages and Innovation

High precision and high quality

Haichen‘s cold chamber die casting machines occupy an advantage in the market with high precision and high-quality casting production capacity.

Among them, the cold chamber die-casting machine of HCD series better controls the temperature and stability of the metal liquid.

Making the casting more uniform and dense, the surface is smooth and delicate.

And the strength and hardness are good, which meets the needs of high-quality products.

Efficient production and automation

Haichen’s cold chamber die casting machines are significantly more efficient than conventional machines.

For example, the HCD series is available in a variety of tonnages and cavities, significantly increasing production efficiency.

In addition, the cold chamber die-casting machine has a high degree of automation.

Which can realize unmanned operation and further improve production efficiency.

Energy saving and environmental protection

Haichen’s cold chamber die casting machines have significant advantages in terms of energy saving and environmental protection.

During its operation, the crystallization time and curing time in the pouring process are reduced.

The energy consumption and waste rate are reduced, and the emission of harmful gases and wastewater is effectively controlled.

Which meets the requirements of environmental protection and embodies the concept of sustainable development.

Technological Advantages and Innovation

Haichen’s die-casting equipment has certain advantages in terms of technology research and development.

For example, HCD series cold chamber die-casting machines have a variety of models, including automatic cold-chamber die-casting machines.

Zinc-aluminum alloy die-casting machines, etc., which can meet the needs of different customers.

In addition, Haichen also pays attention to the customization of products, providing customers with manipulators and other auxiliary equipment, etc.

And can provide personalized solutions according to customer needs.