Common Cooling Problems in Die Casting includes uneven cooling, improper mold temperature control, poure temperature is too high ect.

Cooling problems are very common and critical in the die casting process because they directly affect the quality of castings and production efficiency. The following summarizes common cooling problems and their solutions:

1. Common Cooling Problems in Die Casting: Uneven cooling

Uneven cooling can cause stress inside the casting, which can lead to defects such as shrinkage holes, thermal cracks, and deformation. For example, cooling too fast may cause cold spots or cracks on the surface of the casting, while cooling too slowly may cause pores or shrinkage holes inside the casting.

Solution:

Use appropriate cooling system design, including the size, shape, and location of the cooling channels.

Use a constant temperature control system to ensure uniform mold temperature.

Spray lubricant on the mold surface to reduce thermal shock.

2. Common Cooling Problems in Die Casting: Improper mold temperature control

Excessively high or low mold temperature will affect the quality of the casting. For example, if the mold temperature is too high, the molten metal may adhere to the mold, resulting in surface defects of the casting; while if the mold temperature is too low, the molten metal may have poor fluidity and increase the risk of cold closure.

Solution:

Check and adjust the mold temperature to ensure that it is within a reasonable range.

Optimize the pouring temperature to avoid too high or too low.

3. Common Cooling Problems in Die Casting: Pouring temperature is too high

Pouring temperature that is too high can aggravate the shrinkage problem of the casting, causing depressions or deformations on the casting surface

Solution:

Control the pouring temperature within an appropriate range to ensure that the molten metal can solidify evenly.

4. Insufficient cooling time

If the cooling time is insufficient, the casting may not be fully solidified, resulting in internal defects such as shrinkage cavities or unfilled areas.

Solution:

Extend the cooling time or increase the flow rate of the cooling medium.

5. Unreasonable mold design

Defects in mold design (such as poor venting and unreasonable gate design) can lead to uneven cooling, which in turn causes defects.

Solution:

Optimize mold design to ensure good venting and reasonable gate layout.

6. Thermal fatigue damage

The mold is prone to thermal fatigue damage during repeated heating and cooling, which shortens the mold life.

Solution:

Choose mold materials that are resistant to high temperatures and thermal fatigue.

Use appropriate heat treatment processes to improve the mold’s thermal fatigue resistance.

7. Mold surface temperature fluctuations

Severe fluctuations in mold surface temperature can lead to thermal stress concentration, which can cause mold cracking or deformation.

Solution:

Use a preheating system to gradually increase the mold temperature to a stable state.

Avoid rapid cooling, especially during mold downtime.

The cooling problem in the die casting process involves many aspects, including mold design, cooling system design, pouring temperature control, etc. By optimizing these factors, the quality of castings and production efficiency can be significantly improved.

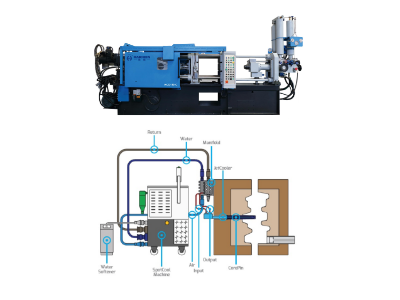

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.