Common Die casting mold Problems & Solutions:

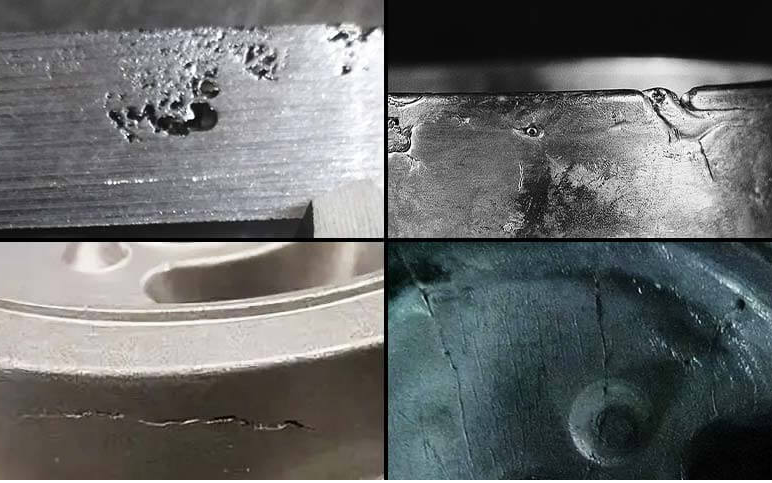

- Porosity & Blowholes

- Cold Shut & Cold Flow

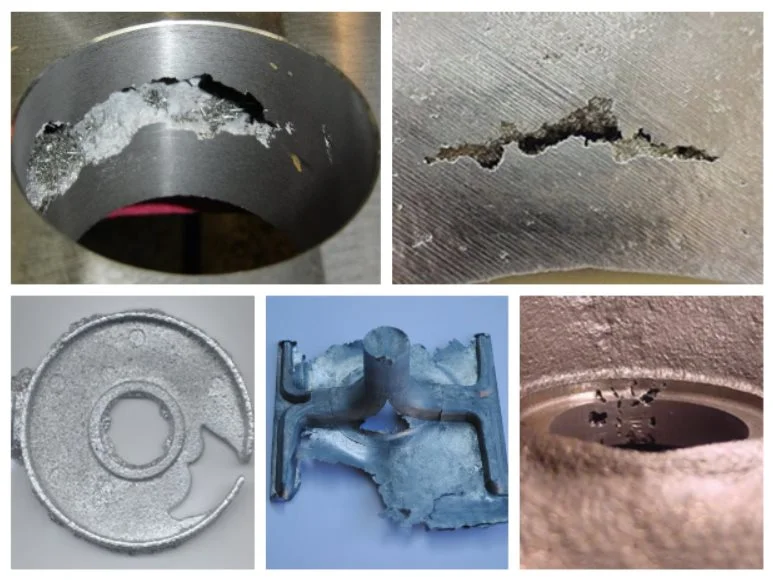

- Cracks & Fractures

- Shrinkage & Porosity

- Warpage & Dimensional Deviation

- Sticking & Erosion

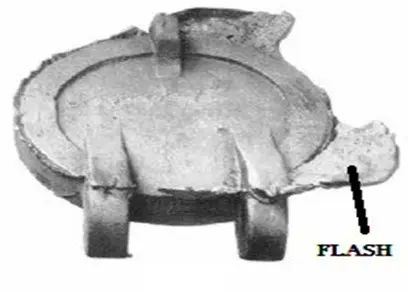

- Flash & Burrs

- Surface Roughness & Oxidation

Die casting mold problems are closely related to temperature control, mold design and process parameters.

Defects can be significantly reduced and yield improved through systematic optimization e.g., simulated filling analysis, vacuum assistance, precise mold temperature control.

And strict process management e.g., alloy composition control, degassing treatment.

Die casting mold problems

Die casting is a manufacturing process that utilizes high-pressure molten metal to create complex metal parts.

It is a versatile process that can be used to produce a wide variety of parts, including automotive parts, electronics enclosures, and medical devices.

At the beginning of the advent of zinc die casting technology, it quickly became an ideal subsessor for other alloys such as tin and lead due to its light weight and high cost performance.

The die casting process, while reliable, can sometimes be fraught with flaws.

Haichen will help you gain a comprehensive understanding of common die casting mold defects, their causes, and practical solutions, which are essential for creating high-quality castings.

Die-casting mold materials

Common die casting mold problems may also stem from the manufacturing materials you choose.

Among them, hard spots refer to the phenomenon where the hardness of a local area of a die-casting mold increases.

Therefore, the hardness distribution of the manufactured die-castings is uneven, which may affect the structural integrity of the die-castings.

This defect may be caused by issues such as uneven cooling during mold manufacturing, improper alloy composition, or poor temperature control during the cooling or solidification process.

Therefore, Haichen will control the die-casting temperature to ensure uniform heating and cooling, thereby eliminating these problems.

In addition, appropriate quality control measures should be taken, such as verifying the alloy composition before die-casting and checking each manufacturing stage during the die-casting process.

Die casting mold problems–Porosity & Blowholes

- Genesis

- Solution

Genesis

Gas entrapment: Molten metal is entrapped in air or release agents during the filling process.

Creating smooth round or oval cavities commonly found in thick-walled or intersecting areas .

Poor exhaust: The design of the mold exhaust system is unreasonable, and the gas cannot be effectively discharged.

High gas content of molten metal: incomplete degassing during the smelting process leads to residual dissolved gases such as hydrogen.

Solution

Optimize mold design

Add exhaust grooves and overflow grooves to ensure that the exhaust area is sufficient and the position is reasonable.

Process adjustments

Reduced filling speed to reduce turbulence, vacuum die casting technology is used to assist with venting.

Melting control

Inert gas (such as argon) is used for degassing, and the temperature of the molten metal is controlled to avoid overheating.

Die casting mold Problems–Cold Shut & Cold Flow

- Genesis

- Solution

Genesis

Insufficient temperature: The melt metal or mold temperature is too low, resulting in incomplete fusion of the flow front.

Low filling speed: The molten metal flows too slowly, and the two streams of metal cannot fuse when they meet.

Improper runner design: The flow path is too long or the cross-sectional area is too small, resulting in the loss of molten metal energy.

Solution

Temperature control

Increase the pouring temperature (e.g. aluminum suitable alloy temperature to 680-720°C) and mold preheating temperature (150-250°C recommended).

Optimized runner

Shorten the metal flow, increase the cross-sectional area of the inner gate, and adopt a multi-strand shunt design.

Increase injection pressure

Enhance metal-hydraulic kinetic energy to improve filling.

Die casting mold Problems–Cracks & Fractures

- Causes

- Solution

Causes

Stress concentration: unreasonable design of the casting structure.

Such as sharp corners, sudden changes in wall thickness, or uneven ejection force.

Improper alloy composition: High levels of impurities (e.g., iron, zinc) lead to increased brittleness.

Uneven mold temperature: local overheating or overcooling leads to differences in shrinkage stress.

Solution

Structural optimization: increase the rounded corner transition, avoid abrupt changes in wall thickness, and reasonably design the position of the ejector rod.

Process improvement: control the mold opening time to avoid premature ejection; Adjust the mold cooling system to uniform the temperature.

Material management: Strictly control the alloy composition and reduce the impurity content.

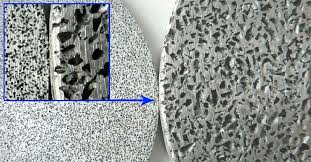

Shrinkage & Porosity

- Causes

- Solution

Causes

Insufficient shrinkage: The volume shrinkage is not effectively compensated for when the molten metal is solidified.

Local overheating: The hot joint area of the mold cools too slowly, forming rough shrinkage holes.

Solution

Pressurized compression: Increase the specific pressure of the shot (e.g., 2000-20000 psi) and extend the dwell time.

Mold optimization: Setting up quenching blocks or local intensive cooling in the hot joint area.

Gating System Adjustments: Place the inner gate in a thick-walled area to prioritize shrinkage.

Warpage & Dimensional Deviation

- Causes

- Solution

Causes

Improper mold fit: Misalignment of the moving and fixed mold or core deviation leads to out-of-tolerance of the size.

Large temperature gradient: uneven mold spraying leads to local shrinkage differences in castings. Residual stress: Deformation caused by premature ejection or insufficient concession.

Solution

Mold maintenance: Regularly check the accuracy of the core and parting surface, and repair the worn parts.

Spray optimization: Evenly spray the release agent to avoid local temperature drops.

Process control: Extend the mold retention time and release the residual stress by annealing process.

Sticking & Erosion

- Causes

- Solution

Causes

Rough surface of the mold: the surface finish of the cavity or sprue is insufficient, and the molten metal adheres to it.

Excessive temperature: Local overheating of the mold causes the alloy to react with the steel mold.

Solution

Surface Treatment: Nitride, chrome or PVD coating of the mold to improve wear resistance.

Temperature control: Use a mold temperature machine to equalize the mold temperature and prevent overheating.

Flash & Burrs

- Causes

- Solution

Causes

Insufficient clamping force: The gap between the parting surfaces of the mold leads to the overflow of molten metal.

Mold wear: After long-term use, the matching accuracy of the parting surface or core decreases.

Solution

Equipment calibration: Increase clamping force or replace a larger tonnage die casting machine.

Mold repair: re-grind the parting surface and replace the worn core.

Surface Roughness & Oxidation

- Causes

- Solution

Causes

Mold contamination: residual mold release agent or oxide in the cavity.

Metal oxidation: Exposure to air during smelting or pouring.

Solution

Cleaning and maintenance: Regularly clean the mold and use ultrasonic cleaning.

Inert protection: Shielding gases (e.g. nitrogen) are used to cover the furnace and pouring process.

What are the reasons for the pattern of die castings after anodizing?

After anodizing, die-cast aluminum parts usually show uneven, dark, spotted or gray patterns because their complex and uneven surfaces contain a high silicon content.

Which hinders the formation of a clear oxide layer, resulting in black spots or gray films instead of a bright surface.

The patterns can include “voids” produced by polishing, defects exposed beneath the surface, or spots of silicon separation.

Achieving uniform surface treatment requires specific pretreatment and anodizing techniques (such as sulfuric acid) for processing.