Plunger Ring Issues in Die Casting include wear and tear, thermal fatigue, and material buildup, which can lead to reduced sealing efficiency, increased metal leakage, and inconsistent shot volumes.

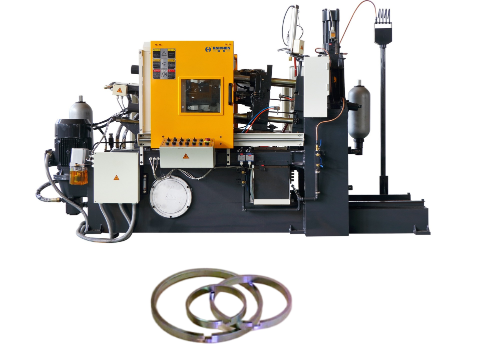

In die casting production, the pusher ring is directly related to whether the molten metal can be smoothly injected into the mold cavity.

This component needs to work continuously under high temperature and high pressure environment. Operators often encounter various problems caused by the pusher ring in actual production, such as uneven ejection force causing deformation of the casting, or improper pusher adjustment leaving surface marks. These failures not only affect production efficiency, but may also lead to scrapping of castings.

This article will specifically analyze the common failure modes of the pusher ring, such as force imbalance caused by uneven distribution of the ejector pin, and fit failure caused by wear on the end of the pusher pin, and provide targeted solutions to help engineers optimize the production process.

Functions and core roles of die-cast push rod rings

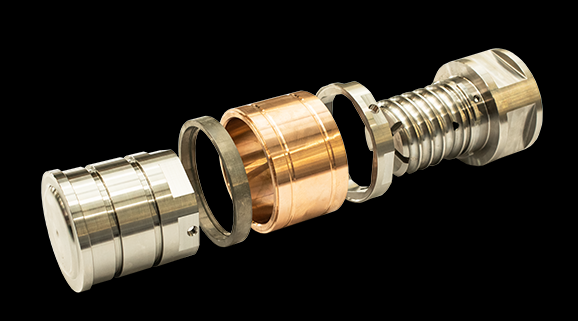

As one of the core components of the die-casting machine, the push rod ring is directly installed on the push rod head. It undertakes three key tasks:

- Sealing protection: forming a physical barrier when injecting molten metal under high pressure, effectively preventing metal liquid leakage and ensuring complete filling of the mold cavity;

- Force transmission: evenly distributing the axial thrust of the push rod to the entire mold contact surface to avoid deformation of the casting due to uneven force;

- Durability guarantee: buffering the impact force and mechanical friction of the metal liquid through special material design, significantly extending the service life of the push rod system

Plunger Ring Issues in Die Casting

Wear and Tear

The piston ring will wear out during the continuous contact with molten metal. The scouring effect of the hot metal will gradually erode the surface of the piston ring, resulting in reduced equipment accuracy and increased metal leakage.

Solution

Operators need to check the condition of the piston ring regularly and replace the worn parts in time. It is recommended to use high-quality materials that are resistant to high temperatures to make piston rings. This method can significantly extend the life of parts and reduce the frequency of replacement.

Thermal Expansion

When the plunger ring contacts the hot molten metal, the material will expand thermally. Engineers have observed that this expansion may cause the plunger ring to shift in position with the injection system. Once the shift occurs, the flow of the molten metal becomes unstable, and defects may occur on the surface of the final casting.

Solution

To address this problem, Haichen die-casting machines use a dual technical solution:

- Active temperature control system: The plunger ring temperature is adjusted in real time through an intelligent cooling device to keep it in a stable working range;

- Application of low-expansion materials: The plunger ring is made of a special alloy, and its thermal expansion coefficient is more than 30% lower than that of conventional materials, which reduces the risk of shifting from the root.

Metal Adhesion

Metal adhesion occurs when molten metal sticks to the plunger ring, creating a buildup that can affect the ring’s performance. This adhesion can lead to increased friction, wear, and potential damage to the ring.

Solution

To prevent metal adhesion, We suggests applying a high – temperature lubricant or anti – adhesion coating to the plunger ring. Regular cleaning of the ring to remove any metal buildup is also crucial in maintaining its performance.

Inconsistent Metal Flow

Inconsistent metal flow can be caused by issues with the plunger ring, such as uneven wear or damage. This inconsistency can result in defects like porosity, incomplete filling of the mold cavity, and surface imperfections.

Solution

Ensuring the plunger ring is in good condition and properly aligned with the injection system is key to maintaining consistent metal flow. HAICHEN‘s precision – engineered plunger rings and injection systems are designed to work together seamlessly. Providing optimal metal flow and high – quality castings.

Deep-seated analysis of push rod ring failure

| Cause category | Typical manifestations | Technical root cause |

| Material wear | Sealing surface scratches, ring body thinning | Insufficient precipitation of hard phase, hardness lower than HRC45 |

| Failure of thermal management | Thermal cracks, deformation | Coolant flow <10L/min or temperature difference >50℃ |

| Insufficient lubrication | Abnormal noise, friction coefficient >0.15 | Lubrication interval >500 cycles |

| Design defects | Local stress concentration | Push rod area <15% of the cavity projection area |

Performance comparison and selection suggestions of push rod rings made of different materials

| Material | Wear resistance | Temperature resistance (℃) | Thermal shock resistance | Applicable scenarios | Cost |

| H13 tool steel | ★★★★☆ | ≤600 | ★★★☆☆ | Heavy die casting (such as automotive parts) | Medium |

| Silicon carbide (SiC) | ★★★★★ | ≤1400 | ★★★★★ | High temperature alloy die casting | High |

| Reinforced polyimide | ★★☆☆☆ | ≤300 | ★★★☆☆ | Small precision parts | Low |

| Titanium alloy | ★★★☆☆ | ≤800 | ★★★★☆ | Lightweight demand scenario | High |

Selection principle:

- When the operating temperature exceeds 550°C, we usually choose silicon carbide (SiC) or H13 steel with surface nitriding because they can maintain stable performance at high temperatures;

- If there is a risk of corrosion in the environment, chrome-plated steel or titanium alloy will be a better option, and their anti-rust effect is better;

- When the budget is limited, reinforced polyester materials with a regular replacement plan will be more cost-effective.

To keep your die casting running smoothly and producing high-quality parts, you need to tackle the common problems that affect your plunger ring. Focus on understanding and fixing issues like wear and tear, heat expansion, metal sticking to the ring, and uneven metal flow. When you manage these well, your plunger rings will work at their best.