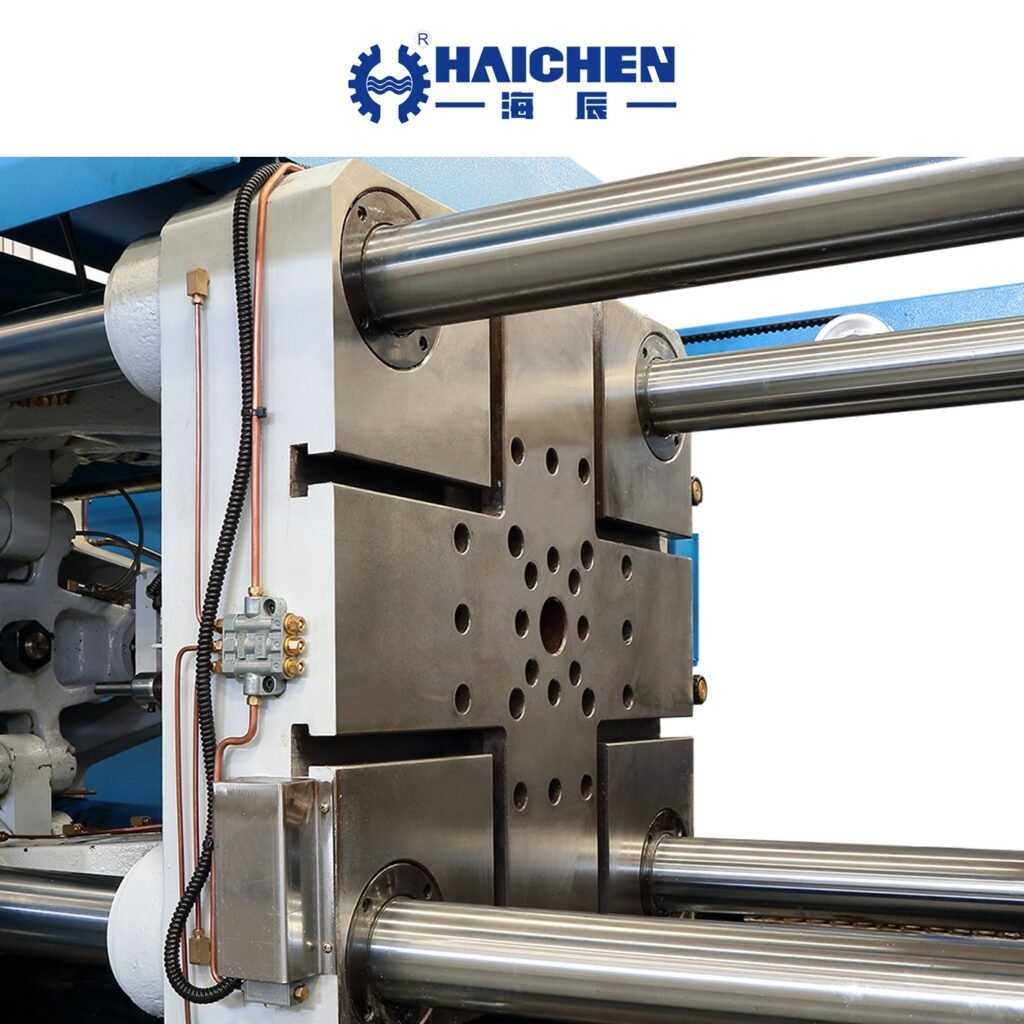

During the die-casting process, one of the common issues is related to the tie bars of the die-casting machine. It is critical components that connect the two halves of the die-casting mold, primarily functioning to transmit pressure to keep the mold closed.

Common Tie Bar Issues & Solutions

However, in actual operations, tie bars may encounter the following problems and corresponding solutions:

Tie Bar Over-Stretching or Breakage of die casting tie bars

Tie bars are stretched during each injection cycle to provide sufficient clamping force to resist the high-pressure injection force. If the machine settings are improper or the tie bars are subjected to excessive stretching, they may break.

Solutions:

- Regularly inspect the stress conditions of the tie bars, using measuring tools such as strain gauges to detect the elongation of the tie bars.

- Adjust the clamping force of the machine to avoid overloading the tie bars with excessive force.

- Ensure that the installation and maintenance of the machine comply with specifications to prevent tie bar failure due to equipment aging or damage.

Uneven Load Distribution on die casting Tie Bars

During high-pressure die-casting, changes in the mold’s center of gravity can lead to uneven load distribution on the tie bars, resulting in issues such as flash.

Solutions:

- Optimize mold design to align the mold’s center of gravity with the injection point, reducing the imbalance of load on the tie bars.

- During the mold design phase, use calculations and simulation analysis to determine the load distribution on each tie bar and allocate the load reasonably.

- Adjust the mold’s center of gravity, for example, by moving the injection point to balance the load on the tie bars.

Tie Bar Wear or Corrosion of die casting tie bars

Long-term use can lead to surface wear or corrosion of the tie bars, affecting their mechanical properties.

Solutions:

- Manufacture tie bars using high-quality materials and regularly lubricate and maintain them.

- For corrosive environments, apply anti-corrosion coatings or replace with corrosion-resistant materials.

Improper Installation of Tie Bars

If tie bars are installed incorrectly, it may prevent the mold from closing properly or create additional stress.

Solutions:

- Carefully inspect the dimensions and positioning of the tie bars before installation to ensure they match the mold and machine.

- Use specialized tools to measure the parallelism and elongation of the tie bars to ensure installation accuracy.

Incorrect Load Calculation for Tie Bars

In some cases, errors in calculation or improper parameter settings may lead to unreasonable load distribution on the tie bars, thereby affecting the quality of die-casting.

Solutions:

- Use professional die-casting simulation software for load calculations and adjust according to actual production conditions.

- Regularly calibrate and validate the calculation models to ensure their accuracy.

Unreasonable Mold Design Leading to Tie Bar Issues

Defects in mold design, such as uneven wall thickness or improper gate design, can cause uneven stress on the tie bars.

Solutions:

- Optimize mold design to ensure uniform wall thickness and proper gate placement.

- Use computer-aided design (CAD) tools for mold design and simulation to reduce design flaws.

Die casting machine supplier : Haichen Machinery

Haichen Machinery is a well-known Chinese manufacturer of cold chamber die casting machines and hot chamber die casting machines, primarily serving the aluminum, zinc, and magnesium die casting industries. Tie bars in Haichen die casting machines are critical for maintaining clamping force and ensuring machine stability during high-pressure injection.

By addressing these issues proactively, you can extend tie bar life, improve casting quality, and reduce machine downtime.