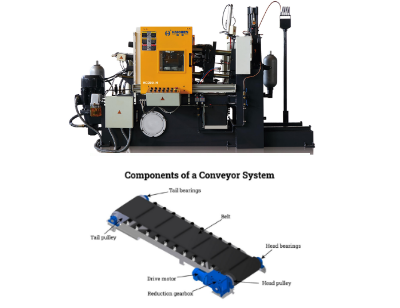

Components of Belt Conveyor in die casting inclues conveyor belts, ldlers, drive pulleys, tensioning devices, loading and unloading devices,etc.

What is belt conveyor ?

Belt conveyor is a continuous transportation equipment. It widely uses in industries, mining, ports, logistics, etc., It uses to transport various bulk materials or finished goods. Its main features include high efficiency, low energy consumption, simple structure, easy maintenance and strong adaptability.

These components work together to ensure that the belt conveyor operates efficiently in die casting production. For example, during the die casting process, hot castings that have just left the mold are grabbed by a robot. And place on a slow-moving conveyor belt for cooling.

In addition, the conveyor belt can also equip with an RFID scanning system for casting identification in automated production lines.

Conveyor belts

Conveyor belts are the core components of belt conveyors. Usually it made of textile materials covered with rubber or plastic, with longitudinal and transverse strength.

Its structure includes woven fiber fabric and covering layer, which can withstand tensile forces and maintain shape.

Structural Composition

- Textile Base Fabric: Made of a warp-and-weft interwoven fabric, it provides longitudinal and transverse strength.

- Cover: A rubber or plastic layer covers the base fabric to enhance wear, oil, and high-temperature resistance.

- This composite structure maintains its shape under tensile stress, ensuring smooth conveying.

Common Materials and Types

(Suitable for the high-temperature, oily environments of die-casting workshops)

- Ordinary Rubber Belts: Suitable for conveying general materials.

- Oil-Resistant Rubber Belts: Suitable for die-casting scrap containing oil or lubricants.

- High-Temperature Resistant (T3) Rubber Belts: Withstand operating temperatures of 150°C–175°C, suitable for high-temperature conveying of post-hot die-casting material blocks.

- Specialized belts, such as flame-retardant, wear-resistant, and acid- and alkali-resistant, can be selected based on site requirements.

Performance Requirements

- High Tensile Strength: Able to withstand the weight and impact loads of die-casting scrap.

- Abrasion and Corrosion Resistance: Maintains surface integrity after extended operation, reducing replacement frequency.

- Flexibility and elasticity: Ensures smooth operation on turns, slopes, and climbs.

- Sealing: Prevents metal chips and coolant leaks, keeping your workshop clean.

Idlers

Idlers use to support and protect conveyor belts. Moreover, it can ensure that they remain stable during operation. Idlers are divided into two types: straight rollers and self-aligning rollers. They usually install on the load-bearing side of the conveyor route to support loads and materials.

The basic functions

- Supporting the conveyor belt: Bearing the weight of the conveyor belt and its load.

- Maintaining belt tension and alignment: Preventing deviation and minimizing lateral movement.

- Reducing impact: Elastic padding absorbs shock at loading points or turns, extending the life of the conveyor belt.

Materials

- The frame and shaft are typically made of high-strength carbon steel with a rust-proof surface treatment (hot-dip galvanizing or painting).

- Sealed ball bearings or roller bearings are used to meet dust and water resistance requirements and are suitable for high-temperature and humid workshop environments.

Dimensions and Load Capacity

- Common pulley diameters range from 6 to 8 inches, with widths selected based on the conveyor belt width (300 to 800 mm).

- Load ratings are determined according to CEMA standards (Classes C, D, and E). Die-cast scrap is generally rated for CEMA Class D or higher.

Mounting Location

- Linear or trough rollers are used on the load side (material inlet, conveyor section).

- Self-aligning or impact rollers are used at bends and lifting points to prevent deviation and impact.

- On the return side, return rollers or self-aligning return rollers are used to ensure smooth rewinding of the empty belt.

Drive Pulleys

Drive pulleys drive the conveyor belt through a motor. They are usually made of steel plate or cast iron. And they equip with bearings to reduce friction and wear. Then the position of the drive pulley determines the direction of movement of the conveyor belt.

Materials

Most are made of steel or cast iron, balancing strength and processing cost.

Bearing Configuration

Heavy-duty anti-friction bearings are used to reduce operating resistance and extend service life.

Position Determines Direction of Movement

The drive pulley’s mounting position (head or tail) directly determines the belt’s direction of travel, often placed at the discharge end for greater traction.

Structural Integrity

The housing, end plates, hub, and bearings are formed into a rigid unit through locking devices and couplings, ensuring stability under high loads and long-term operation.

Tensioning Devices

Tensioning devices use to adjust the tension of the conveyor belt. So that can ensure that it does not slip or slack during operation. Common tensioning methods include weight tensioning and spring tensioning.

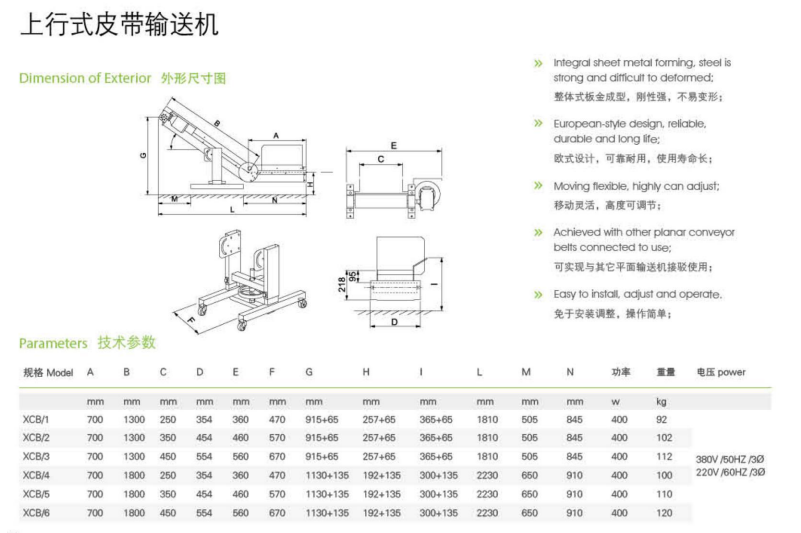

Haichen conveyor advantages

Haichen’s dedicated conveyor systems are engineered to streamline post-casting automation, offering key advantages in efficiency and reliability.

Their robust construction ensures seamless, continuous transport of hot castings from the machine to downstream processes like trimming or cooling. Customizable in length and speed, they synchronize perfectly with production cycles to eliminate bottlenecks. Designed for low maintenance and durability in harsh foundry environments, these conveyors enhance workplace safety by removing manual part handling, reduce labor costs, and significantly boost overall production line throughput.

This integration ensures a smooth, automated workflow for maximum operational productivity. Please see attached Haichen conveyor belt parameter.

Loading and Unloading Devices

These devices use to feed material into or remove material from the conveyor belt. For example, when material loading through a hopper, feeder or side plate/skirt, or material is unloaded using a push plate or scraper.

Cleaning Devices

Cleaning devices use to remove material residues accumulated on the conveyor belt. That to prevent conveyor belt wear. Common cleaning methods include scraper cleaning and rotating brush cleaning.

Auxiliary Components

Auxiliary components include protective covers, sealing blocks, impact plates, buffer pads, and so on. Which are used to protect the conveyor belt and ensure smooth flow of materials.

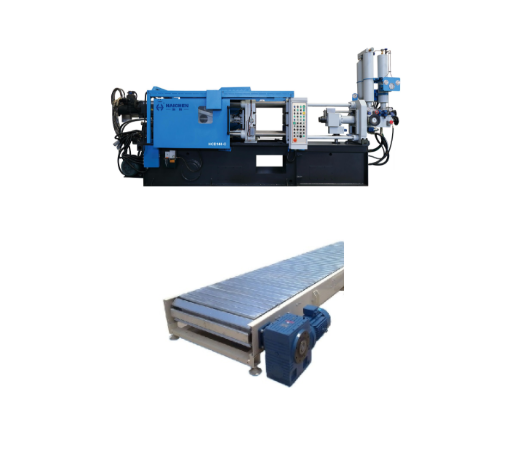

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.