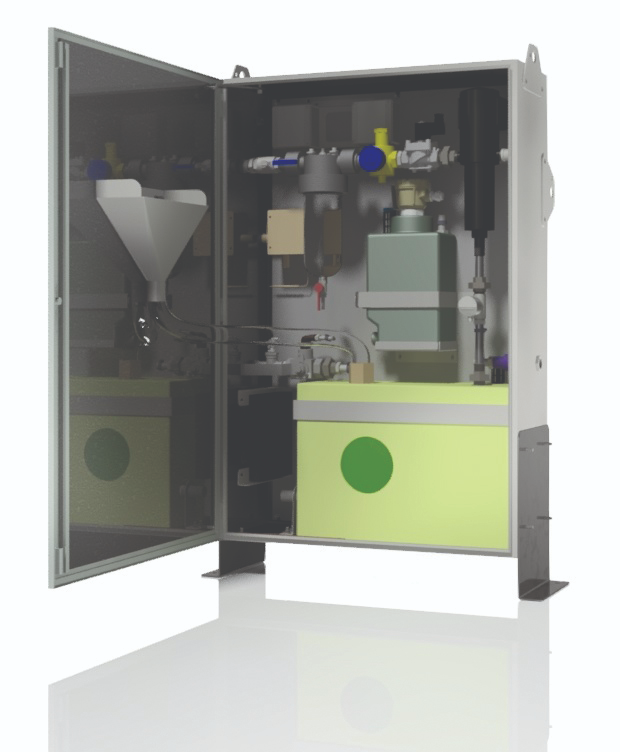

Components of release agent mixer includes components such as the mixing container, stirring mechanism, control system, auxiliary system.

The mold release agent mixer is mainly used in the preparation of mold release agents in industrial production.

To ensure the uniform mixing of mold release agent components and improve the mold release effect.

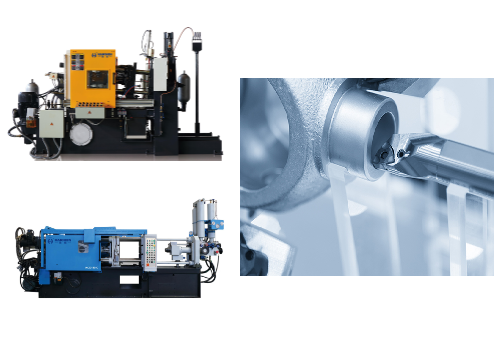

The fully automatic die-casting release agent automatic mixer is suitable for the foundry industry.

Especially for die-casting aluminum and cast iron materials.

Mold release agents are very important in industries such as casting, automotive manufacturing (especially integrated die-casting), plastics and rubber products.

Therefore, as a device for preparing mold release agents, the demand for mixers increases along with the growth of these industries.

The definition and core functions of the mold release agent mixer

- High-efficiency mixing

- Automation control

- Adapt to diverse demands

The mold release agent mixer is an industrial equipment specifically designed for preparing mold release agents.

It uniformly mixes the various components of the mold release agent.

Such as oil, water, emulsifiers, additives, etc, through physical or mechanical means to ensure the stable performance of the mold release agent.

High-efficiency mixing

Solve the stratification problem of solid suspensions such as wax, silicone oil.

And liquids in mold release agents, ensuring the uniformity of components.

Automation control

The fully automatic model equips itself with a PLC system to precisely adjust the stirring time and speed, reducing manual intervention.

The equipment’s inherent automation features reflect the automation of the release agent mixer in the Haichen die-casting machine.

Such as fully automatic mixing and the overall automation trend of the die-casting system such as central control systems, robotic control, etc.

However, despite the limited independent automation control details for the release agent mixer itself, the automation technologies of the overall die-casting system.

Such as automated control, sensors, PLCs,provide support for the automation application of the release agent.

Adapt to diverse demands

It can handle water-based, oil-based and mixed mold release agents, meeting the requirements of different industries for the viscosity, temperature resistance and other characteristics of mold release agents.

Mold release agent mixer

We designed the mold release agent mixer to mix the mold release agent with other materials or liquids.

Its primary role is to disperse the mold release agent uniformly into the required medium.

Through methods such as grinding, it achieves high-efficiency and uniform mixing.

Drawing on Haichen’s production experience, we widely use the equipment in die-casting industries.

It ensures the formation of a separation layer between the metal processing mold surfaces, facilitating demolding operations and improving product quality.

Mold release agent

Release agent (e. g. Chem-Trend) usually water-miscible, sprayed onto the wall of the die casting mold during pressure die casting.

Which prevents soldering of the metal to the mold and facilitates demolding of the casting.

In pressure die casting, the use of high-quality release agents and their correct application contribute considerably to achieving a high uniform product quality of castings.

In addition, the resource-efficient use of materials has a significant influence on economic efficiency.

Thus, when choosing the right release agent, this results in low material requirements.

And disposal costs, in a prolonged service life of the molds and reduced rejection rates.

In the production of light-metal die castings, the selection of raw materials for release agents plays a critical role.

When it comes to the quality of components and the cycle time of the pressure die casting process.

Requirements for release agents vary depending on the type of metal and alloy.

It is therefore important to not only consider quality-related influencing factors.

Such as film formation, demolding and cooling effect when using water-based release agents for the various die casting alloys.

Such as aluminum, magnesium and zinc alloys, but to also meet the overall requirement profile.

Components of release agent mixer

- Mixing container

- Stirring mechanism

- Control system

- Auxiliary system

Mixing container

Material: Stainless steel (such as 1Gr18Ni9Ti austenitic stainless steel) is usually adopted, which has corrosion resistance, weldability and strength.

It is especially suitable for mold release agents containing corrosive components (such as silicone oil, organic acids, etc.).

Volume: Adjusted according to the production scale, the volume of laboratory-grade equipment can be as low as 1.5L, while that of industrial-grade equipment can reach over 200L.

Sealing design: The airtight structure prevents evaporation or leakage.

Some equipment adopts clamp-type flange sealing and butterfly valve discharge ports to reduce residue.

Stirring mechanism

Low-viscosity liquids (such as water-based release agents) : paddle type, turbine type, and propeller type agitators, operated under turbulent conditions, with the ratio of impeller diameter to container diameter being 0.3-0.6.

High-viscosity liquids (such as wax-based mold release agents) : Anchor, helical ribbon or screw agitators are used to achieve uniform mixing through laminar or transitional flow.

Drive system: The motor power range is from 1.5kW (for small equipment) to 18.5kW.

For industrial equipment, and the speed is adjustable to meet different mixing requirements.

Control system

Automation function: The fully automatic model integrates PLC control to achieve parameter setting (such as stirring time and speed) and process monitoring.

Safety protection: Overload protection, temperature sensor (for high-temperature release agents) and emergency stop function.

Auxiliary system

Heating/cooling device: Some release agents need to be mixed at specific temperatures such as high-temperature resistant silicone oil release agents.

And the equipment may be equipped with jackets or electric heating elements.

Atomization module: The aerosol type mold release agent mixer integrates a high-pressure nozzle to atomize and spray the mixed liquid onto the mold surface.

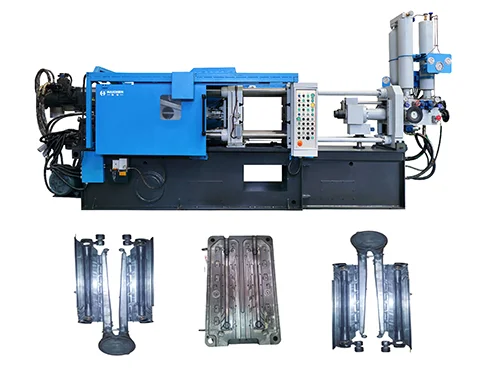

Mold release agent mixer and metal die-casting process

Under the die-casting processes of different types of metals, the mixture of release agents will also vary:

- Aluminum alloy die casting

- Magnesium alloy die-casting

- Zinc alloy die casting

Aluminum alloy die casting

The release agent mixer is widely used in aluminum alloy die casting.

It is used to spray the surface of the mold to form an isolation film, preventing the metal liquid from directly eroding the mold, and improving the forming quality of the casting and production efficiency.

Magnesium alloy die-casting

During the magnesium alloy die-casting process, the release agent mixer reduces mold wear by spraying release agent, ensuring the integrity and surface quality of the castings.

Zinc alloy die casting

The release agent mixer is used in zinc alloy die casting to help the molten metal enter the cavity.

And form a uniform isolation film, thereby improving the demolding performance and quality of the casting.

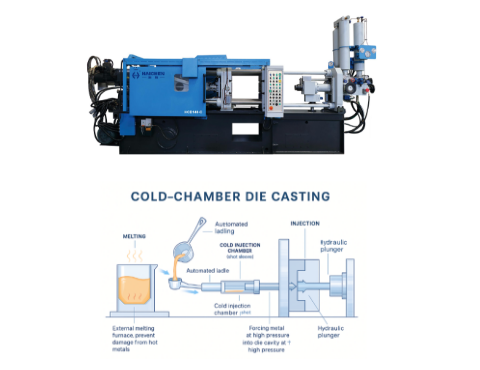

The collaborative process of mold release agent mixer in die-casting technology

- Mold release agent preparation stage

- Pre-treatment stage of die-casting

- Die-casting and post-processing stage

Mold release agent preparation stage

The mixer blends the original mold release agent solution with water in a specific ratio (e.g., 1:140) and forms a stable emulsion via agitators or emulsifying pumps.

Haichen’s mold release agent mixer comes with a recovery device that separates oil and water from unused mold release agent, filters and reclaims them, thus reducing production costs.

Pre-treatment stage of die-casting

The mixed release agent is conveyed through pipelines to the spraying device of the die-casting machine.

And evenly covers the surface of the mold in the form of atomization, forming a high-temperature resistant (400-600℃) isolation film.

The spraying volume needs to be precisely controlled (usually 0.1-0.3L/m²).

Excessive spraying will cause gas holes on the surface of the casting, while insufficient spraying is prone to sticking to the mold.

Die-casting and post-processing stage

The release agent reduces the thermal shock of the mold during the metal liquid filling process, lubricates the flow channels at the same time, and improves the filling integrity.

After the casting is demolded, the residual mold release agent is collected through the collection system of the die-casting machine chassis and enters the oil separator for treatment to prevent environmental pollution.