A servo motor in die casting is basically an electric motor that offers very fine control over motion at a certain position, over speed, and torque. Major parts include a rotor-the moving part inside the machine; stator- as the stationery part outside the moving component; encoder, or resolver- these devices provide information regarding where exactly the moving part is located; controller-this adjusts movement based on information from the encoder.

Servo motors give precision control of motion and are usually applied in applications needing accurate positioning with repeatability. Advanced feedback mechanisms enable precise position, speed, and torque control.

You would find use at various speeds for which high torque is available from servo motors, making possible application in complex machinery and robotics among others. They can accelerate, decelerate, and reverse very fast; hence improved performance in dynamic applications.

Servo motors in die casting machines are designed to be precise and durable. They’re also made to fit well with high-

Servo motor in die casting machines are engineered for precision, durability, and integration with high-force industrial processes.

What Servo Motor have in Die Casting machine?

Let‘s find out.

Below are the key components and their roles in this specialized application:

- Motor Stator and Rotor

- Encoder

- Servo Drive/Controller

- Feedback System

- Gearbox

- Cooling System

- Electromagnetic Brake

- Connectors and Cabling

- Mounting Hardware

- Protective Casing

Motor Stator and Rotor

- Function: The stator (stationary coils) and rotor (rotating magnets) generate motion through electromagnetic induction.

- Die Casting Relevance: Designed for high torque and rapid response to handle dynamic loads during injection and clamping.

Encoder

- Function: Provides real-time feedback on position, speed, and direction to ensure precise control.

- Die Casting Relevance: Critical for accurate mold alignment, injection velocity control, and repeatability in high-pressure cycles.

Servo Drive/Controller

- Function: Converts command signals into precise electrical currents to control motor operation.

- Die Casting Relevance: Adjusts injection pressure, clamping force, and ejection timing based on process requirements.

Feedback System

- Components servo motor in die casting: Encoders, temperature sensors, vibration monitors.

- Die Casting Relevance: Ensures stability under thermal stress and detects anomalies (e.g., overloads) to prevent defects.

Gearbox

- Function: Amplifies torque while reducing speed for high-force applications.

- Die Casting Relevance: Used in clamping units to apply thousands of tons of force securely.

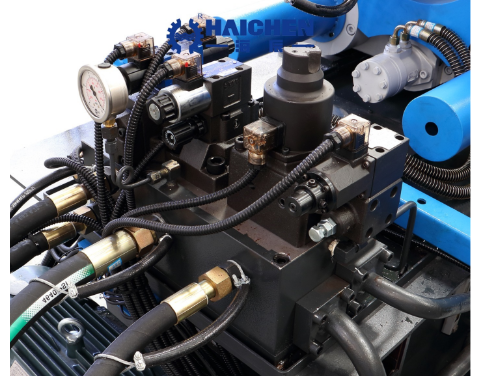

Cooling System

- Types: Air-cooled (fans) or liquid-cooled (water/glycol loops).

- Die Casting Relevance: Prevents overheating during continuous operation near molten metal (up to 700°C ambient).

Electromagnetic Brake

- Function: Locks the motor shaft when power is off.

- Die Casting Relevance: Ensures safety during maintenance and prevents unintended movement in heavy machinery.

Connectors and Cabling

- Specifications: Shielded cables and ruggedized connectors (e.g., IP67-rated).

- Die Casting Relevance: Resists electrical interference and environmental hazards (e.g., metal dust, coolant).

Mounting Hardware

- Examples: Flanges, brackets, and adapters.

- Die Casting Relevance: Secures the motor to withstand vibrations and mechanical stress during high-speed cycles.

Protective Casing

- Materials: Aluminum alloy or stainless steel with IP65/IP67 ratings.

- Die Casting Relevance: Shields against molten metal splatter, dust, and humidity.

Application-Specific Enhancements

- High-Temperature Resistance: Components like seals and bearings use heat-resistant materials (e.g., ceramic coatings) to endure proximity to molten alloys.

- Hybrid Integration: Interfaces with hydraulic systems for synchronized operation in machines like toggle-clamp or injection units.

- Overload Protection: Built-in sensors to detect excessive force, preventing damage during sudden pressure spikes.

Workflow in Die Casting

- Injection Phase: The servo drive signals the motor to push the plunger at a programmed velocity, while the encoder ensures precise displacement.

- Clamping Phase: The gearbox amplifies torque to lock the mold under high pressure, with feedback systems monitoring alignment.

- Cooling/Ejection: The motor adjusts ejection mechanisms smoothly, avoiding part deformation.

Key Considerations

- Environmental Resilience: Select motors rated for high temperatures and particulate ingress.

- Precision Calibration: Regular encoder alignment and drive tuning minimize cycle time deviations.

- Maintenance: Periodic lubrication of gearboxes and inspection of cooling systems extend lifespan.

Servo motor in die casting integrate robust mechanical components with advanced feedback systems to achieve precision in harsh industrial environments. Proper selection and maintenance of these components ensure efficiency, safety, and consistent product quality.

What are the practical advantages of servo motor in die casting?

Advantages of Servo Motors in Die Casting Applications

Servo motors offer significant practical benefits in die casting machines, particularly in energy efficiency, productivity, control precision, and operational cost reduction. Here’s a detailed breakdown:

- Energy Efficiency & Power Savings

- Shorter Cycle Times & Increased Productivity

- Precision Control & Quality Improvement

- Reduced Maintenance & Extended Equipment Life

- Environmental Benefits & Operational Flexibility

- Compact Design & Space Savings

Energy Efficiency & Power Savings

- Servo motors reduce energy consumption by 40–70% compared to traditional hydraulic systems, thanks to optimized hydraulic circuits and closed-loop control. For example, permanent magnet synchronous servo motors minimize energy loss from relief valves (which typically waste 25–80% of energy in conventional systems).

- High dynamic responsiveness (e.g., achieving 0–100% pressure changes within 30 milliseconds) enhances efficiency. Lower hydraulic oil temperatures reduce cooling water usage by 30%, extending component lifespan.

Shorter Cycle Times & Increased Productivity

- Rapid response and precise acceleration/deceleration improve production efficiency by 5–12%. In injection phases, servo pumps eliminate throttling losses from proportional valves, accelerating mold filling.

- Case studies show servo-driven systems improve energy efficiency by 65%, while simplified hydraulic designs (e.g., replacing dual pumps with a single servo pump) further shorten cycle times.

Precision Control & Quality Improvement

- Closed-loop control ensures micron-level accuracy in position and pressure, reducing defects like porosity and shrinkage. Dynamic adjustments during complex part formation enhance dimensional stability.

- Multi-stage pressure control (e.g., precise pressure management in early stages combined with accumulator support) optimizes energy use and process consistency.

Reduced Maintenance & Extended Equipment Life

- Lower thermal stress on hydraulic oil extends component life. Simplified systems (e.g., replacing proportional valves with on/off valves) reduce failure points.

- Oil-cooled servo motors (e.g., Yunsheng’s permanent magnet designs) minimize overheating, lowering downtime.

Environmental Benefits & Operational Flexibility

- Quieter operation and regenerative energy recovery (e.g., servo-controlled cushioning) enhance workplace sustainability.

- Modular control allows independent adjustment of process parameters (e.g., speed for horizontal/vertical die casting), enabling rapid adaptation to diverse production needs.

Compact Design & Space Savings

- Servo-driven systems simplify hydraulic circuits (e.g., single-pump setups replacing dual-pump configurations), reducing machine footprint and maintenance complexity.

Servo motors revolutionize die casting by slashing energy costs, boosting productivity, ensuring precision, and enhancing sustainability. Their integration represents a critical advancement in modern die casting technology.

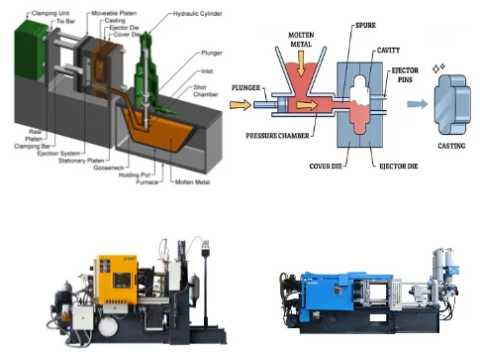

What machine is used for die casting?

The primary machine used in die casting is the die casting machine, which can be categorized into the following types based on process requirements and applications:

- Hot-Chamber Die Casting Machine

- Suitable for low-melting-point alloys (e.g., zinc, tin, lead, magnesium).

- Features a submerged injection system: The molten metal is stored in a heated chamber, and a piston injects the metal directly into the mold.

- High automation and material efficiency, ideal for high-volume production.

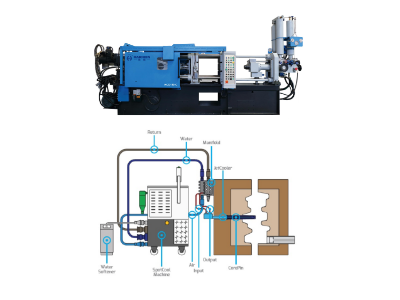

- Cold-Chamber Die Casting Machine

- Used for high-melting-point alloys (e.g., aluminum, copper, magnesium).

- Molten metal is ladled from an external furnace into a cold chamber, then injected into the mold. This design minimizes corrosion caused by prolonged contact with molten metal.

- Aluminum die casting (common in automotive parts) typically uses cold-chamber machines.

- Gravity Die Casting Machine

- Relies on gravity to fill the mold with molten metal.

- Used for materials like brass or iron alloys where high pressure is unnecessary.

- Ultra-Large Die Casting Machine

- Designed for integrated large-scale components (e.g., automotive structural parts). Examples include UBE’s UB6500iV2 and China’s Yizumi LEAP series (e.g., 9,000-ton machines).

- Reduces part count and simplifies manufacturing processes, especially in electric vehicle production.

Key Features

- High Pressure & Rapid Injection: Hydraulic systems apply extreme pressure (700–1,200 bar) to force molten metal into molds, enabling thin-walled, high-precision parts.

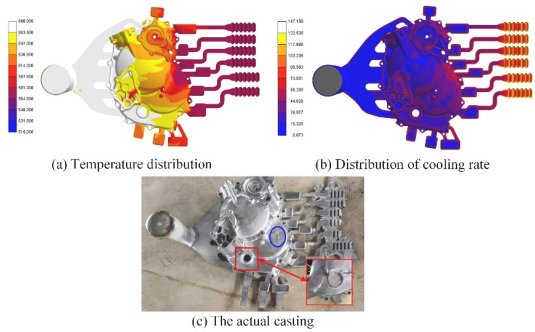

- Mold & Cooling Systems: Molds are made of hardened tool steel (e.g., H13 steel) with integrated cooling channels to solidify metal quickly and reduce porosity.

- Vacuum-Assisted Die Casting: Advanced machines use vacuum technology to evacuate air from the mold cavity, improving surface finish and density.

Applications

Die casting machines are widely used in automotive parts, household appliances, electronics, and industrial components. Integrated die casting (e.g., Tesla’s “Giga Press”) is revolutionizing electric vehicle manufacturing by producing large, complex parts in a single step.

Haichen widely uses servo motor technology in various die-casting machines produced by us, mainly for precise control of injection units, energy-saving optimization and automation integration.

Our servo system technical solutions have fully demonstrated the core role of servo systems in improving die-casting quality and efficiency. At the same time, it has achieved environmentally friendly production, which meets the needs of modern industry for green manufacturing.

Come and contact us if you have any needs for new technology die-casting industrial machinery and equipment.