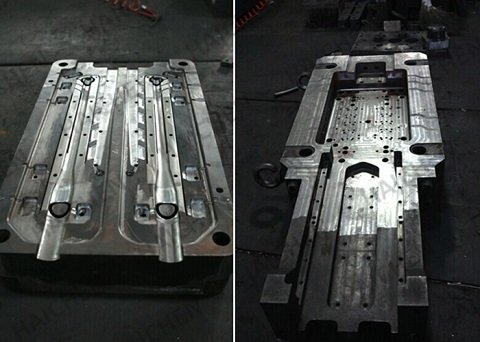

Composition of the quick mold change system: clamp, mould transfer arm, mould lifter, pneumatic and hydraulic power unit, control system and so on.

The Quick Mold Change System is a mold replacement solution for molding equipment. Such as injection molding machines, stamping machines, and die casting machines. Its main purpose is to shorten mold replacement time, improve production efficiency, reduce costs, and improve product quality.

The quick mold change system composition consists of a clamp, a mold transfer arm, a mold lifter, a gas-liquid power unit, a control system and a mold change cart, etc.

It uses hydraulic or pneumatic power to achieve quick mold change. Its main advantages are shortening mold change time, improving production efficiency and reducing costs. It is suitable for a variety of molding equipment and industry scenarios.

Main components

- Clamp of quick mold change system composition

- Mould transfer arm of quick mold change system composition

- Mould lifter of quick mold change system composition

- Pneumatic and hydraulic power unit

- Control system

- Mold change car of quick mold change system composition

Clamp of quick mold change system composition

It used to fix the mold to ensure the stability and safety of the mold during the replacement process.

Mould transfer arm of quick mold change system composition

It’s responsible for moving the mold from one position to another. And it usually used in conjunction with the mold lifter.

Mould lifter of quick mold change system composition

Lifts or lowers the mold from the platen through pneumatic or hydraulic power to facilitate the installation and removal of the mold.

Pneumatic and hydraulic power unit

Provides the necessary power support to ensure the efficient operation of the system.

Control system

Control the entire system through a touch screen or operation panel to simplify the operation process.

Mold change car of quick mold change system composition

Used to transport molds and improve the automation of mold transportation and storage.

Quick mold change system working principle

The quick mold change system completes the steps of unlocking, separating, installing and positioning the mold through automated operations. The specific process includes:

- Positioning and clamping

- Unlocking and separating

- Installation and positioning of the new mold

- Clamping and locking

Positioning and clamping

Fix the old mold on the equipment to ensure its stability.

Unlocking and separating

Separate the mold from the equipment through the unlocking mechanism.

Installation and positioning of the new mold

Install the new mold in place and position it.

Clamping and locking

Use the clamp to fix the new mold on the equipment.

Advantage of the quick mold change system

- Improved production efficiency

- Enhanced production flexibility

- Reduced labor costs

- Stable quality

Improved production efficiency

Mold change time is reduced by 30-60%, significantly reducing machine downtime.

Enhanced production flexibility

The same machine can complete small batch production of multiple varieties within the same day.

Reduced labor costs

Standardized mold change procedures enable minimal or no human operation.

Quick mold change system composition: Stable quality

Fast and precise positioning reduces human error and lowers defective product rates.

Future trend

- Rising demand for flexible manufacturing

- Integration of digitalization and intelligence

- Standardization of modular molds

Rising demand for flexible manufacturing

Industries like automotive and consumer electronics require small batches and a wide variety of products, making rapid mold change a key technology for achieving flexible production.

For example, Haichen adopts aluminum die casting machine techniques to proudce high-quality aluminium alloy cookware pans. Under high-pressure die casting (HPDC) cold chamber die casting machine.with exceptional efficiency and performance.

By injecting molten aluminum into precision steel molds under intense pressure, this process enables the rapid production of pots with complex, thin-walled geometries and excellent dimensional consistency. The result is lightweight yet durable cookware with superior heat distribution.

Key advantages include high production speeds, minimal material waste, and the ability to integrate reinforced structures and intricate surface details directly into the casting, ensuring both functional excellence and aesthetic appeal in every piece.

Haichen can also produce replaceable pot bottom moulds for same diameter with different bottom shape pans. That can help save and reduce customer’s significant cost.

Integration of digitalization and intelligence

Industrial Internet platforms enable predictive maintenance and automated scheduling of mold change processes, further shortening mold change windows.

Standardization of modular molds

Suppliers are introducing standardized mold interfaces (such as the Quick-Mold series from Germany and the United States), reducing companies’ in-house R&D costs.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine and hot chamber die casting machine. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.