Thermocouples in die casting:

- Surface Thermocouple

- Core Thermocouple

- Near Casting-Die Interface

- Multiple Thermocouples for Complex Dies

- General Installation Tips

Thermocouples play a crucial role in the die casting process, mainly used to monitor and control mold temperature, molten metal temperature, and interfacial heat transfer in real-time.

To ensure casting quality, optimize process parameters, and improve production efficiency.

Through real-time temperature monitoring in die casting, combined with cooling system optimization, thermocouples can effectively improve mold temperature control accuracy, improve production efficiency and product quality.

Thermocouple for Aluminium Foundry

In aluminum foundries, precise temperature measurement and control are absolutely critical for producing high-quality castings.

Thermocouples serve as the indispensable backbone of this temperature monitoring, providing real-time data on molten aluminum temperatures within melting furnaces, holding furnaces, and ladles.

The unique properties of aluminum, including its relatively low melting point but high reactivity, necessitate accurate temperature management to prevent issues such as excessive dross formation, gas porosity, and inconsistent mechanical properties in the final product.

Thermocouples used in this demanding environment must be robust, capable of withstanding extreme heat, thermal cycling, and potential chemical attack from the molten aluminum and fluxes.

The accurate data provided by thermocouples directly impacts the metallurgical integrity and efficiency of the aluminum casting process.

By allowing foundry operators to maintain molten metal at its optimal pouring temperature, thermocouples help ensure proper grain structure, minimize shrinkage, and reduce the occurrence of cold shuts and other casting defects.

Furthermore, precise temperature control contributes to energy efficiency by preventing overheating and allowing for more optimized furnace operations.

Various types of thermocouples, often with specialized protective sheaths made from ceramics or other high-temperature alloys, are employed to meet the specific challenges and accuracy requirements of different stages within an aluminum foundry.

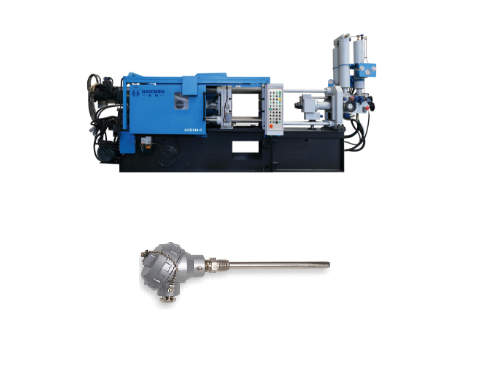

Haichen‘s thermocouples

Haichen carries the Thermocouple Assemblies for Molten Aluminum and Zinc.

The unitized construction combines a Cerite protection tube with an integral thermocouple element to form a COMPLETE THERMOCOUPLE ASSEMBLY.

Non-Wetting Cerite is cast around a 1/4″ NPT steel pipe, which contains an integral 14 gauge ceramic insulated thermocouple element, and the fiberglass-insulated leads.

This combination assembly is a Very COST EFFECTIVE means of measuring molten aluminum process temperatures. Available in various lengths. IN STOCK for immediate delivery.

Special thermocouple assemblies are also available to meet your requirements. Contact us for additional information.

Thermocouples types and Installation Locations

- Surface Thermocouple (Ts)

- Core Thermocouple (Tc)

- Near Casting-Die Interface

- Multiple Thermocouples for Complex Dies

- General Installation Tips

Surface Thermocouple (Ts)

- Location: The surface thermocouple hole should be located in the center of the largest area of the die on the backside. It should be at least 1/4T x 1/4W or mid-radius from the nearest corner.

- Depth and Diameter: The hole should be 1/8” to 1/4” (3.2mm to 6.4mm) in diameter and 0.625” ± 0.125” (15.9mm ± 3.2mm) deep. Thus, the thermocouple can accurately measure the surface temperature by maintaining an optimal position that avoids excessive exposure or recession.

Core Thermocouple (Tc)

- Location: Preferably, place the core thermocouple as close to the center of mass as possible, typically by utilizing existing coolant holes. If this is not possible, a representative load block with a thermocouple at its center of mass should be used.

- Purpose: This placement helps in monitoring the internal temperature of the die. It is essential for understanding the cooling rate and ensuring uniform heat treatment.

Near Casting-Die Interface

- Location: For accurately determining the heat transfer coefficient (HTC) between the casting and the die, thermocouples should be placed near the casting-die interface. This helps in capturing the temperature changes during the solidification process.

- Distance: The thermocouples should be placed 6–10 mm from the casting surface. This proximity ensures that the temperature measurements reflect the conditions at the interface accurately.

Multiple Thermocouples for Complex Dies

- Location: For example, in complex die designs, multiple thermocouples such as Ts1, Ts2, and Ts3 can monitor different sections of the die. This is particularly useful for large dies or those with varying thicknesses.

- Guidelines: Therefore, position each thermocouple to capture the temperature variations in its specific section. For example, thermocouples can be placed at different steps of a “step shape” casting to study the heat transfer profiles.

General Installation Tips

- Secure Wires: Thermocouple wires must be secured to prevent movement during quenching or other operations.

- Avoid Direct Contact:When using a waterline hole for a thermocouple, pack it with a fiber refractory material to prevent direct contact with the quenchant.

- Accessibility: The thermocouples should be accessible during the heat treatment process for monitoring and maintenance.

The Role of Thermocouples

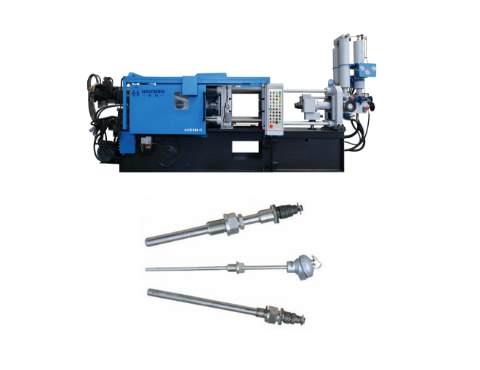

In die casting, operators often embed thermocouples inside the mold to measure temperature at specific points.

For instance, they typically mount these thermocouples at various distances from the inner surface, such as 2 mm, 4 mm, and 8 mm, to record temperature gradients inside the mold.

Some thermocouples measure the surface temperature of the casting directly, for example by bending the tip to ensure close contact with the mold surface.

The mounting method involves inserting the thermocouple from the back or side of the mold.

When inserted from the rear, holes need to be cleared to ensure proper installation.

To overcome installation uncertainty, engineers developed special temperature sensor units that first involve placing thermocouples in a processing tank, then terminating them at a specific distance from the surface, and finally welding them to a fixed position.

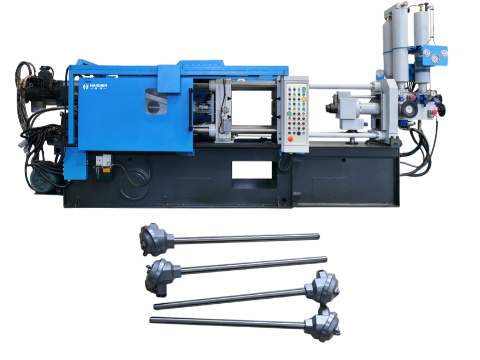

Die casting machine supplier: Haichen Machinery

Haichen Machinery is a supplier of die casting machines and related spear parts.

We specialize in providing die casting production solutions for various materials, including aluminum, magnesium, zinc, and copper alloys.

Our cold chamber and hot chamber die casting machines are used for manufacturing products such as automotive parts, LED lamp shells, radiators, and household appliance components.

It includes critical locations within the mold cavity, at the casting interface, in different areas of the mold, near cooling channels, on the mold cover and push-out side.

In addition, the use of special mounts or non-intrusive techniques can improve the accuracy and reliability of measurements.

Therefore, by properly placing thermocouples, operators can comprehensively monitor the temperature distribution during the die casting process, thus optimizing process parameters and improving product quality.