Defects in zinc die casting can occur due to improper mold design, inadequate material flow, or incorrect process parameters. Some of the defects include surface defects, porosity, and cold shuts.

Zinc die casting is famous for it’s usage in producing parts abundant in detail and intricate features. However, like other processes, it suffers from defects that can affect the operation and performance of the final product.

As with any other process, a good die casting design should guarantee optimal material flow and control of the process parameters to avoid defects. Maintaining best practices also ensures achievable product quality.

Common Defects in zinc die casting

Lowering customer complains and maintaining production standards heavily relies on understanding the defects. In the following section of the article, we attempt to outline the most common problems of zinc die casting.

- Porosity

- Cold Shut

- Inclusions

- Warpage

- Surface Defects

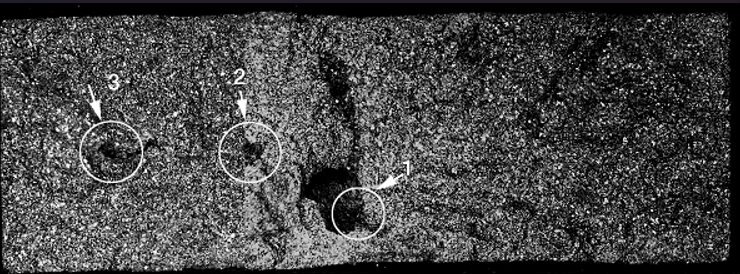

Porosity

Presence of voids or empty spaces in a particualar casting makes it porous. Porosity in die casting comes from air that was trapped in the cavity both during injection and the subsequent die venting process. These voids can weaken zinc parts structurally.

Porosity problem can be rapid injecting of gas, lack of proper vents in the mold, and high temperature within the mold itself.

One method of solving this is to reduce the injection speed. Another could be active going into the vents to remove blockages while providing positive control on the gas and improving temperature control.

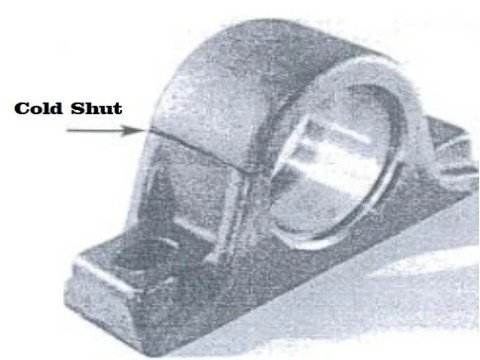

Cold Shut

Failure to unite two or more molten metal fronts properly leads to cold shut where seams or cracks affect the strength and appearance of the metal further hindering its usefulness. This phenomenon occurs in the course of casting if there is low injection speed, low mold temperature or both.

In case the mold temperature is extremely low, the surface layer of the molten metal will cool quickly leading to incomplete fusion on the contact surface, further hindering a seamless part. Cold shut features prominently as seams and cracks which render the part structurally powerless.

A balanced injection of metal into the forming place serves to combine the fluid streams thereby removing the cold shut features. An equably warmer mold also ensures tempered cooling of metal with a balanced level of solidification.

Inclusions

Inclusions refer to a capture of unwanted substance inside a casting. Such unwanted substances may be made up in the form of oxides or other refuse materials. Inclusion can occur due to introduction of impure metal piece, lack of mold care, or flawed feeding systems.

Inclusion can occur due to introduction of impure metal piece, lack of mold care, or flawed feeding systems.

If the zinc alloy has impurities or if the mold is not properly cleaned, these contaminants will mix with the molten metal which makes it very difficult to create clean, contaminate-free final products.

An improperly constructed gating system can trap filthy molten metal beneath the surface which produces inclusions which can lead to premature failures.

In order to make sure no inclusions form in the die casted parts, appropriate measures should be taken to prevent contaminants and inclusions from high purity materials, regular mold maintenance and appropriate gating systems that enables smooth and straightforward direction for the molten metal.

Warpage

Warpage refers to the unusual bending or displacement of a part due to features like improper cooling, uneven temperature gradients, or improper ejection from a mold. Warping can occur due to internal stresses forming from disproportionate cooling of certain sections of a casting. This abnormality impacts the operation and the movement of the part in context to other components.

Surface Defects

Surface imperfections comprise cracks, discoloration, and other non uniform features. Such damage may come from a worn out mold, mold release issues, or contamination on the surface of the mold. Defects that impacts the surface of the part to high degree lead to failure in functionality on the component despite the wanted appearance.

Eliminating Defects in Zinc Die Casting

Proper quality control and process management are needed to prevent the aforementioned defect issues. Maintaining the mold regularly, proper monitoring of the injection parameters, and guaranteeing flawless materials are essential.

Reducing Defects Using HAICHEN Die Casting Machines

At HAICHEN, we know how critical minimizing defects is in zinc die casting for parts accuracy and reliability.

Our die casting machines are efficient and precise. They offer solutions to problems like porosity, cold shut, and inclusions.

Our machines maintain the utmost control over the injection speed, mold temperature, and gating systems. This enables smooth and uniform solidification of the molten zinc, lowering the chances of defects.

Our machines also come with advanced monitoring systems that helps the operator to detect and solve problems in real time, making the product better every time.

Knowing about defects in zinc die casting critically impacts reliability and quality. These processes enable meeting the required standards for quality within the production zinc die castings.